Adjustments

4-4

750-297

Profire E/LNE Series Manual

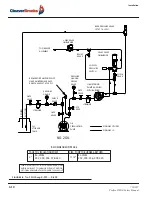

4.4.6 — High Gas Pressure Switch

Turn the adjusting screw until the indicator moves to a pressure setting slightly above the maximum operating gas

pressure. The control will break a circuit if pressure exceeds this value. The control should be adjusted to prevent

operation with excessive gas pressure, but not at a pressure so close to normal operating pressure that unnecessary

shutdowns occur.This switch must be manually reset after tripping. To reset, allow gas pressure to drop and press the

manual reset button.

4.4.7 — Gas Combustion Adjustment

After operating for a sufficient period of time to assure a warm boiler, make adjustments for most efficient

combustion.The butterfly gas valve directly controls the rate of flow. The low fire light-off setting should be regarded

as preliminary until proper gas pressure for high fire operation is established.

Determine the actual gas flow from a meter reading at high fire. With the butterfly valve open and with regulated gas

pressure set, the actual flow rate should be quite close to the required input. If corrections are necessary, increase or

decrease the gas pressure by adjusting the gas pressure regulator, following manufacturer's directions for regulator

adjustment.

When proper gas flow is obtained, take a flue gas analysis reading.

With the high fire air-fuel ratio established, the gas pressure regulator needs no further adjusting.

Recheck low fire and adjust if necessary.

Proper setting of the air-fuel ratios at all rates must be determined by combustion analysis. See Section 4.2 of this

chapter for additional information.

4.5 — Oil System

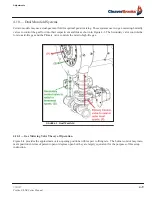

4.5.1 — Oil Metering System

Fuel oil supply to the separate metering unit must be 10 psi to 20 psi. The oil spray should ignite as soon as the oil

solenoid valve opens. If the oil spray fails to ignite, move the metering unit adjustment lever a few degrees

counterclockwise. This increases the amount of oil at low fire and makes ignition easier, it will also increase the oil on

high fire, and this must be checked later. Once adjusted, the pump should operate with a minimum amount of

adjustment. If a burner failure is caused by the oil metering pump, check the following:

1.

Oil tanks are not empty.

2.

All oil valves between the burner and the tank are open.

3.

The suction line is not airbound.

4.

The low fire setting has not been disturbed.

5.

There is pressure at the separate metering unit, but not exceeding 20 psi.

6.

The pump turns freely.

7.

The strainer at the suction side of the circulating pump is not clogged.

8.

The burner strainer is not dirty.

NOTE:

Check for CO through the entire firing range.

Содержание Profire E Series

Страница 2: ...E LNE SERIES Installation Operation and Service Manual Manual Number 750 297 Release Date July 2019...

Страница 24: ...Introduction 1 10 750 297 Profire E LNE Series Manual...

Страница 44: ...Operation 3 8 750 297 Profire E LNE Series Manual...

Страница 70: ...Troubleshooting 6 6 750 297 Profire E LNE Series Manual...

Страница 79: ...750 297 Profire E LNE Series Manual 8 5 LNE Series FGR System FIGURE 8 4 Temperature Interlocks...

Страница 82: ...750 297 Profire E LNE Series Manual...