FILTRATION

FILTRATION

WWW.CLEANCOMFORT.COM

6

IO-AE14-5

INSTALLATION

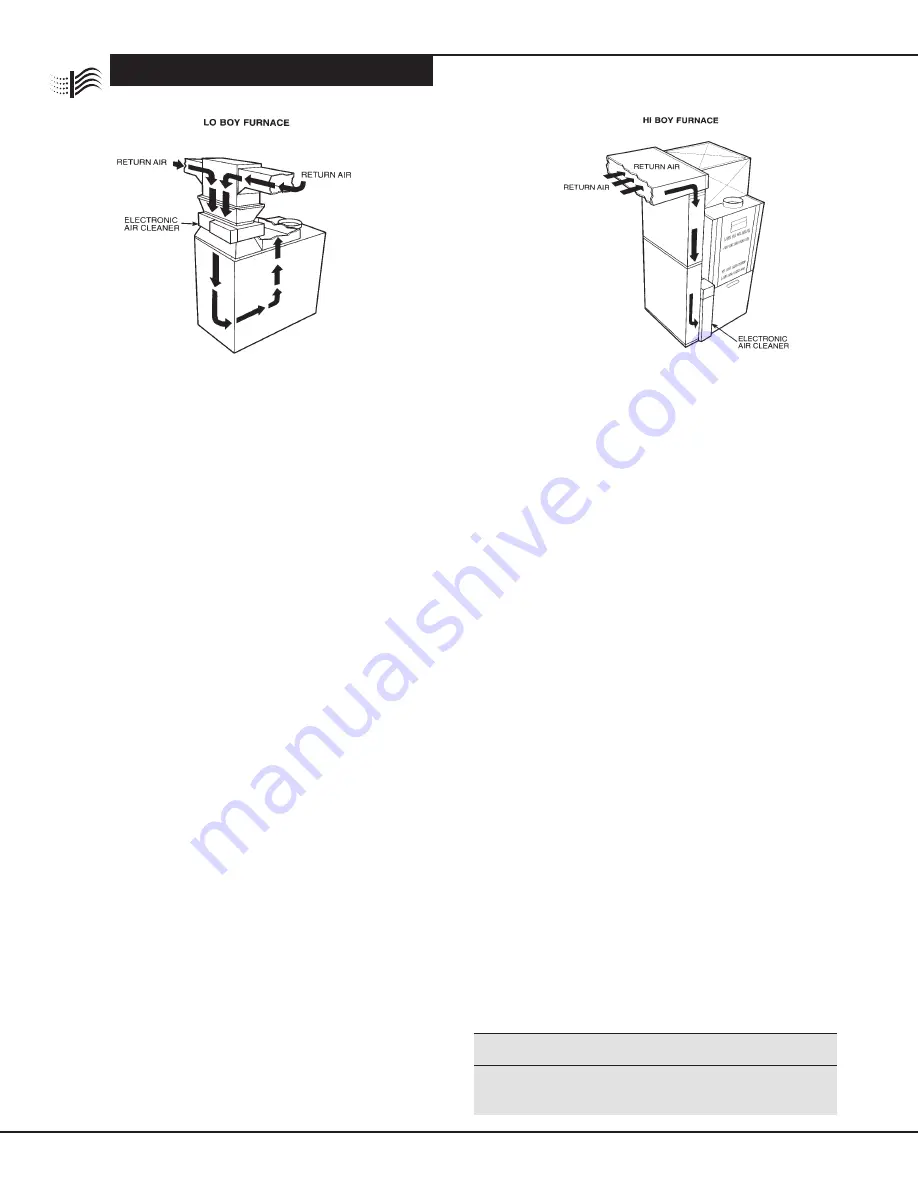

Figure 5:

Air Cleaner

Installation Location

Allow 24 in. (60 cm) clearance for maintaining air cleaner

Allow 6 in. (15 cm) clearance for power box removal.

Installation Location with Humidifier

A humidifier should be installed in the furnace warm

air duct. However, it may be installed in the return duct

without causing problems to the air cleaner. Care must

be taken to ensure that the humidifier does not leak, as

this may cause arcing and a mineral deposit to build up

on the collecting cells.

An atomizing type humidifier should be installed

downstream from the air cleaner. If the atomizing type

humidifier is installed upstream, high humidity, salts and

minerals may decrease the efficiency of the collecting

cells and cause service problems.

If the atomizing type humidifier must be installed

upstream, the following precautions should be taken:

1. Atomizing type humidifier must be installed as far

from the air cleaner as possible.

2. Collecting cells must be washed frequently to

prevent a mineral deposit build-up.

Installation Location with Air Conditioner

Whenever possible, the air cleaner should be installed

upstream of the cooling coil. This location will clean the

air before it reaches the evaporator coil.

Installation Steps

1.

Remove existing equipment filter (if present) and

clean blower compartment:

Thoroughly clean the

blower compartment, since your air cleaner can not

remove accumulated dirt from the blower chamber

and distribution ducts.

2.

Open air cleaner access door. Slide filters and

collecting cells out of cabinet.

3. Installing the cabinet: Holes are provided to attach

cabinet to ductwork or equipment. If the adjoining

ductwork is flanged, install the screws so that the

screw heads are inside the cabinet. This will help

prevent damage to prefilter and carbon VOC filters

during removal for cleaning. Never put screws or

rivets into the removable power box.

4.

Transitions: If the air duct does not fit the air cleaner

opening, a gradual transition is recommended to

reduce air turbulence through the air cleaner and

ensure its efficient operation. A maximum of 20° of

expansion, or approximately 4 inches per running foot

(10 cm per 30 cm ), is recommended for each side of

the transition fitting.

Do not reduce ductwork size to fit a smaller

air cleaner. This will increase the velocity of

airflow and may decrease cleaning efficiency.

5.

Turning vanes: If the air cleaner is installed adjacent

to an elbow or angle fitting, field-installed turning

vanes are recommended to improve air distribution

across the collecting cells.

6.

Seal the joints in the return air system: All joints

between the air cleaner, the heating / cooling

equipment and the return air duct should be sealed

to prevent dust from entering the clean air stream.

7.

Replace the prefilters in the track on the air entering

side of the air cleaner. Place new carbon VOC filters

into the air cleaner. Space filters evenly across the

discharge opening of air cleaner. Never put more

than 3 carbon VOC filters in the air cleaner, as this

may cause a problem with airflow.

The collecting cells are placed between the tracks, with

the arrow on cell pointing towards the fan. The cell

handle may need to be repositioned if the airflow is in

a different direction than the left to right set up. The

handle should face the door. Close access door.

i

WARNING!

Electrical shock can cause injury or death. Be certain main

line disconnect switch is

OFF

before wiring.