7

Parts & Service: 020 8988 7400 / E-mail: [email protected] or [email protected]

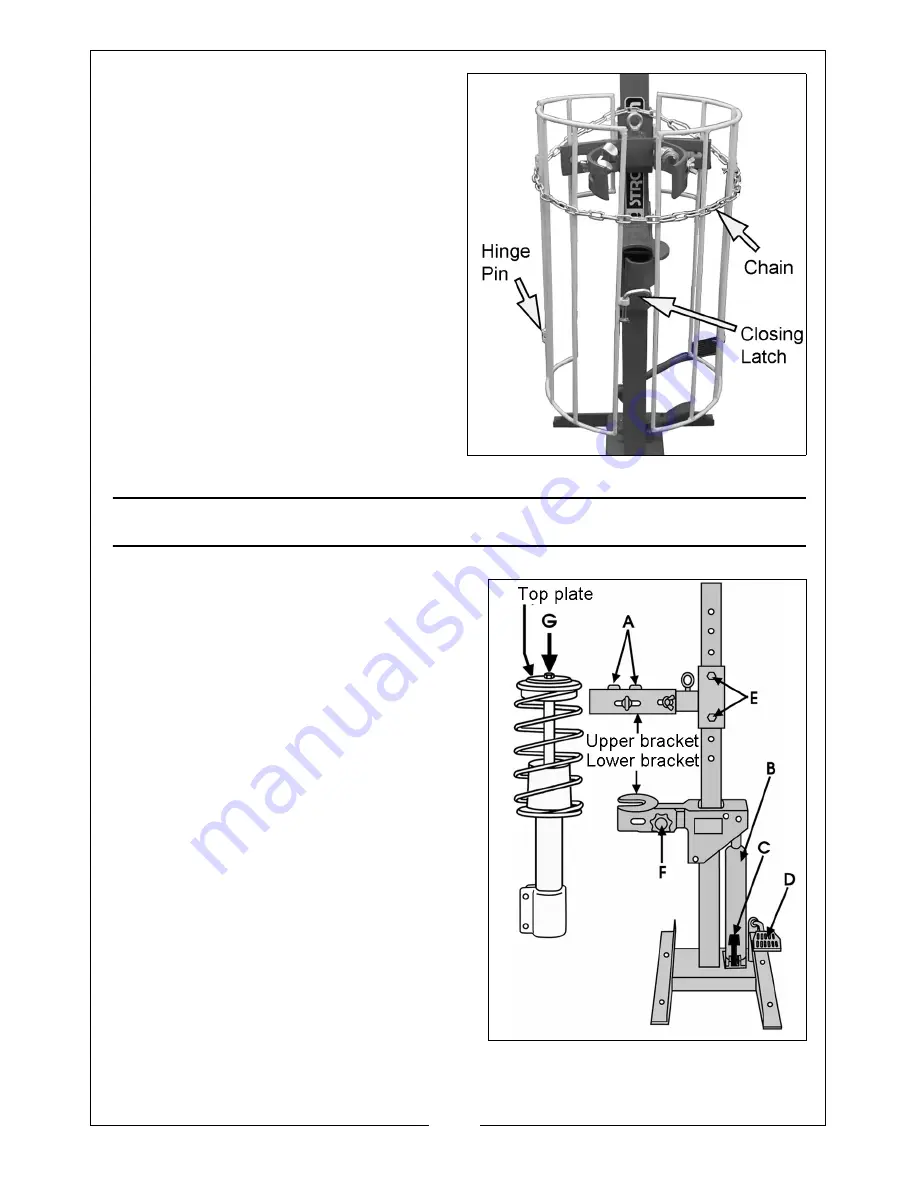

2. Add the outer guards to the inner

guards, locating them using the

hinge pins supplied and lock with

split pins.

3. Fit the closing latch to the guards.

4. Before operating the compressor,

the safety chain should be

wrapped around the inner and

outer guards as shown,

connecting the two chain ends

with the snap hook.

OPERATION

1. Press and hold down the release

valve pedal ‘C’ to lower the ram to

its lowest position.

2. Hinge the upper brackets back,

3. Slide the suspension leg into the

lower bracket and clamp in place

using the clasp and knob ‘F’. Do not

overtighten - it should only be firm.

4. Position the upper bracket so that

the two clamps ‘A’ fit snugly and

squarely around the spring coils, as

near to the top of the assembly as

possible.

•

It may be necessary to remove the

two pins securing the upper bracket

assembly ‘E’ and slide the bracket up

or down by the appropriate amount

in order to locate the clamps ‘A’

correctly. Ensure the pins ‘E’ are

locked by the R-clips before

proceedin

g.

Содержание SSC1000G

Страница 12: ......