6

Parts & Service: 020 8988 7400 / E-mail: [email protected] or [email protected]

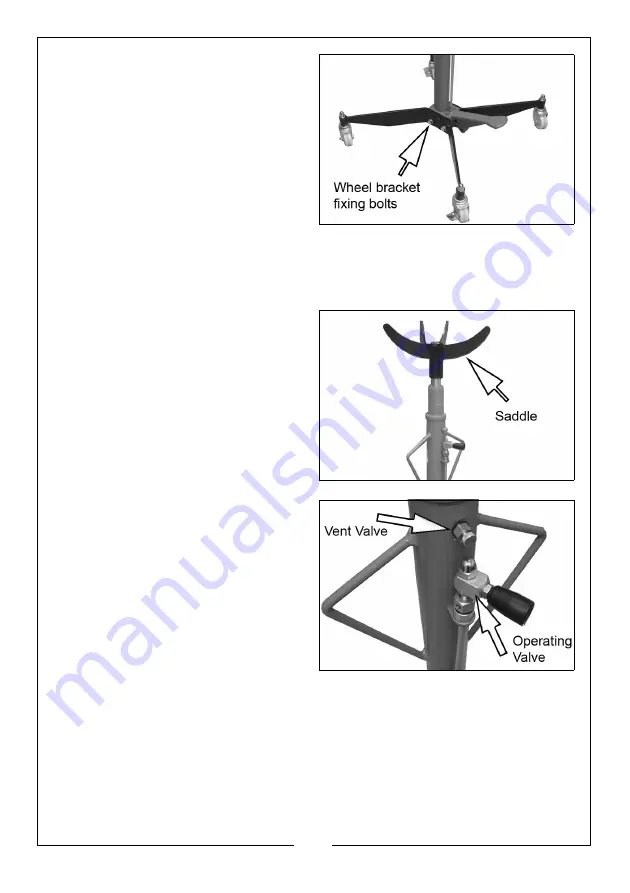

4. Lay the column on its side, and

bolt on the two wheel bracket

assemblies, with the castors facing

downwards ensuring the bracket

sits over the locating peg. Use the

two bolts and washers. Loosely

tighten the bolts, but DO NOT fully

tighten at this stage.

5. Raise the jack to the upright

position, resting on its castors and

ensure it is on firm level ground.

6. Using a set-square, and testing in two directions at 90° to each other,

ensure the column is vertical. When satisfied, tighten the column securing

bolts fully.

7. Place the saddle on top of the

ram.

8. Loosen the vent valve by hand.

• This will allow air to be vented

when the ram is descending.

NOTE:S

During transit or storage, it is possible that an air pocket may have developed

within the hydraulic ram, and the ram action may therefore appear to be

‘spongy’. As the ram is self bleeding, any air will be dispelled via the vent valve

and the ram action normalised, by raising and lowering the column a few

times while not under load.

If the column does not reach its full height, the ram oil level may require

topping up, as described in the Maintenance section.