11

Parts & Service: 020 8988 7400 / E-mail: [email protected] or [email protected]

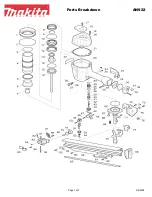

SPARE PARTS LIST

No

Description

Part No

No

Description

Part No

01

Hex. Skt Hd Screw

HTCSN1D01

42

Compression Spring

HTCSN1D42

02

Compression Spring

HTCSN1D02

43

Roll Pin 2.5x16

HTCSN1D43

03

Air Deflector

HTCSN1D03

44

Safety Plate

HTCSN1D44

04

Cap Screw M5x20

HTCSN1D04

45

Trigger

HTCSN1D45

05

Lock Washer 5mm

HTCSN1D05

46

Cap Screw M4x10

HTCSN1D46

06

Cylinder Cover

HTCSN1D06

47

Lock Waher

HTCSN1D47

07

O-Ring 13.7x2.4

HTCSN1D07

48

Nose Cover

HTCSN1D48

08

Sealing Washer

HTCSN1D08

49

Drive Guider

HTCSN1D49

09

Compression Spring

HTCSN1D09

50

Spacer

HTCSN1D50

10

Head Valve

HTCSN1D10

51

Nose

HTCSN1D51

11

Sealing Washer

HTCSN1D11

52

Cap Screw M4x14

HTCSN1D52

12

O-Ring 31.2x2.5

HTCSN1D12

53

Bar

HTCSN1D53

13

O-Ring 24.8x3.5

HTCSN1D13

54

Roll Pin 1.5x10

HTCSN1D54

14

Sealing Gasket

HTCSN1D14

55

Insert

HTCSN1D55

15

Collar

HTCSN1D15

56

Magazine

HTCSN1D56

16

O-Ring 41.7x3

HTCSN1D16

57

Scale

HTCSN1D57

17

O-Ring 26.2x2.4

HTCSN1D17

58

Magazine Label

HTCSN1D58

18

Cylinder

HTCSN1D18

59

Inlay Slice

HTCSN1D59

19

O-Ring 21x3

HTCSN1D19

60

Tube

HTCSN1D60

20

Piston Assembly

HTCSN1D20

61

Catch Lever

HTCSN1D61

21

Bumper

HTCSN1D21

62

Compression Spring

HTCSN1D62

22

Gun Body

HTCSN1D22

63

Pusher Pipe

HTCSN1D63

23

Rubber Washer

HTCSN1D23

64

Pusher

HTCSN1D64

24

O-Ring 1.7x2

HTCSN1D24

65

Compression Spring

HTCSN1D65

25

Pin

HTCSN1D25

66

Washer

HTCSN1D66

26

Safety Seat

HTCSN1D26

67

Fixed Seat

HTCSN1D67

27

Compression Spring

HTCSN1D27

68

Cap Screw M4x38

HTCSN1D68

28

E-Clip 6mm

HTCSN1D28

69

Pin

HTCSN1D69

29

TUV Drive Stand

HTCSN1D29

70

Flat Head Screw

HTCSN1D70

30

TUV Adjusting Nut

HTCSN1D30

71

Cap Screw M4x6

HTCSN1D71

31

Hex Nut M4

HTCSN1D31

72

Support Seat

HTCSN1D72

32

Compression Spring

HTCSN1D32

73

Washer

HTCSN1D73

33

Steel Ball 2mm

HTCSN1D33

74

Cap Screw M4x20

HTCSN1D74

34

Safety Yoke

HTCSN1D34

75

Rubber Handle Grip

HTCSN1D75

35

Rectangle Washer

HTCSN1D35

76

O-Ring 36.3x3.55

HTCSN1D76

36

Piston Valve

HTCSN1D36

77

End Cap

HTCSN1D77

37

Compression Spring

HTCSN1D37

78

Air Plug

HTCSN1D78

38

Valve Stem

HTCSN1D38

79

Air Plug Cover

HTCSN1D79

39

O-Ring 2.5x1.5

HTCSN1D39

80

O-Ring 2.4x1.6

HTCSN1D80

40

Trigger Valve Guide

HTCSN1D40

81

Cap Screw M4x14

HTCSN1D81

41

O-Ring 11.2x2

HTCSN1D41