7

Parts & Service: 020 8988 7400 / E-mail: [email protected] or [email protected]

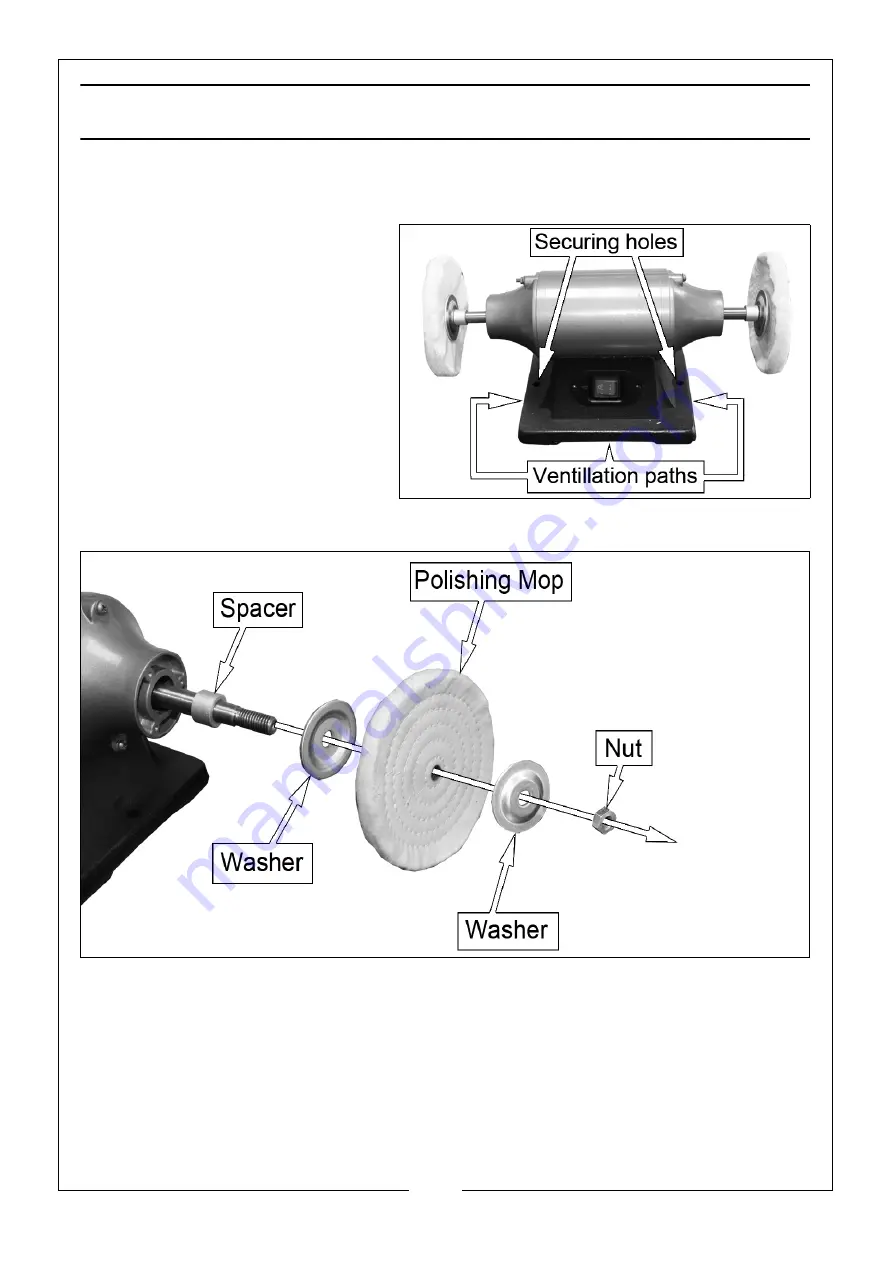

ASSEMBLY

MOUNTING THE MACHINE

1. Bolt the buffer/polisher to a

workbench using the

securing holes shown.

• Check that all assembly

nuts and bolts are secure

before turning the

machine on.

• DO NOT block the

ventilation paths through

the base.

FITTING BUFFING/POLISHING PADS

1. Place the spacer over the shaft.

2. Place the polishing mop between the washers and secure with the retaining

nut, hand tight.

• The shaft threaded ends are handed LH and RH.

3. Tighten the nuts enough to grip without crushing the buffing/polishing pad.

NOTE:

Wheel rotation, in use, will tighten the retaining nut.

Содержание 6500485

Страница 12: ......