8

Parts & Service: 020 8988 7400/E-mail:[email protected] or [email protected]

ELECTRICAL CONNECTIONS

WARNING! Read these electrical safety instructions thoroughly

before connecting the product to the mains supply.

Before switching the product on, make sure that the voltage of your electric-

ity supply is the same as that indicated on the rating plate. This product is

designed to operate on 230VAC 50Hz. Do not connect it to any other power

source.

This product may be fitted with a non-rewireable plug. If it is necessary to

change the fuse in the plug, the fuse cover must be refitted. If the fuse cover

becomes lost or damaged, the plug must not be used until a suitable re-

placement is obtained.

If the plug has to be changed because it is not suitable for your socket, or

due to damage, it should be cut off and a replacement fitted, following the

wiring instructions shown below. The old plug must be disposed of safely, as

insertion into a mains socket could cause an electrical hazard.

WARNING! The wires in the power cable of this product are

coloured in accordance with the following code:

Blue = Neutral Brown = Live

If the colours of the wires in the power cable of this product do not corre-

spond with the terminal markings of your plug, proceed as follows.

•

The wire which is coloured

Blue

must be connected to the terminal which

is marked

N

or coloured

Black

.

•

The wire which is coloured

Brown

must be connected to the terminal

which is marked

L

or coloured

Red

.

Plug must be BS1363/A approved.

Always fit a 13 Amp fuse.

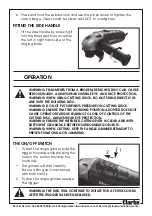

Neutral

Live

(Blue)

(Brown)

Ensure that the outer sheath of the cable is firmly held by the clamp

We strongly recommend that this productis connected to the mains supply

via a Residual Current Device (RCD).

If in doubt, consult a qualified electrician. DO NOT attempt repairs yourself.

This symbol indicates that this is a Class II product and does not require

an earth connection.

Содержание 6470144

Страница 1: ...OPERATING MAINTENANCE INSTRUCTIONS Model No CAG900 PART NO 6470144 GC0614 ANGLE GRINDER...

Страница 20: ......