- 2 -

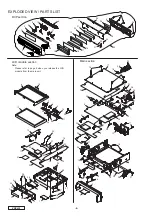

VRX630

COMPONENTS

QC-6710B-A

Main unit

-----------

1

Remote control unit

RCB-130-601

1

Battery(SUM-3)

-----------

2

Universal mounting bracket

300-9677-00

1

DCP case

335-6035-41

1

Power supply lead

854-6356-51

1

Outer escutcheon

940-7715-04

1

Parts bag(No.1)

-----------

Flat head screw(M5x8)

714-5008-41

4

Sems hexagonal bolt(M5x8)

716-0496-01

5

Parts bag(No.2)

-----------

Hook plate

331-0488-20

2

Cord clamp

335-0833-07

1

Spacer

345-3653-20

1

Screw

716-0726-01

1

To engineers in charge of repair or

inspection of our products.

Before repair or inspection, make sure to follow the

instructions so that customers and Engineers in

charge of repair or inspection can avoid suffering

any risk or injury.

1. Use specified parts.

The system uses parts with special safety features against

fire and voltage. Use only parts with equivalent character-

istics when replacing them.

The use of unspecified parts shall be regarded as remod-

eling for which we shall not be liable. The onus of product

liability (PL) shall not be our responsibility in cases where

an accident or failure is as a result of unspecified parts

being used.

2. Place the parts and wiring back in their original positions

after replacement or re-wiring.

For proper circuit construction, use of insulation tubes,

bonding,gaps to PWB, etc, is involved. The wiring connec-

tion and routing to the PWB are specially planned using

clamps to keep away from heated and high voltage parts.

Ensure that they are placed back in their original positions

after repair or inspection.

If extended damage is caused due to negligence during

repair, the legal responsibility shall be with the repairing

company.

3. Check for safety after repair.

Check that the screws, parts and wires are put back se-

curely in their original position after repair. Ensure for

safety reasons there is no possibility of secondary ploblems

around the repaired spots.

If extended damage is caused due to negligence of repair,

the legal responsibility shall be with the repairing company.

4. Caution in removal and making wiring connection to the

parts for the automobile.

Disconnect the battery terminal after turning the ignition

key off. If wrong wiring connections are made with the bat-

tery connected, a short circuit and/or fire may occur. If ex-

tensive damage is caused due to negligence of repair, the

legal responsibility shall be with the repairing company.

5. Cautions regarding chips.

Do not reuse removed chips even when no abnormality is

observed in their appearance. Always replace them with

new ones. (The chip parts include resistors, capacitors,

diodes, transistors, etc). The negative pole of tantalum

capacitors is highly susceptible to heat, so use special care

when replacing them and check the operation afterwards.

6. Cautions in handling flexible PWB

Before working with a soldering iron, make sure that the

iron tip temperature is around 270 . Take care not to ap-

ply the iron tip repeatedly(more than three times)to the

same patterns. Also take care not to apply the tip with force.

7. Turn the unit OFF during disassembly and parts replace-

ment. Recheck all work before you apply power to the unit.

ERROR DISPLAYS

If an error occurs,one of the following displays is displayed.Take the measures described below to eliminate the problem.

CD

changer

MD

changer

Error display

ERROR 2

ERROR 3

ERROR 6

ERROR H

EEROR 2

ERROR 3

ERROR 6

Cause

A CD inside the CD changer is not loaded.

A CD inside the CD changer cannot be played due to

scratches,etc.

A CD inside the CD changer cannot be played because it

is loaded upside-down.

Displayed when the temperature in the MD changer is

too high and playback has been stopped automatically.

An MD inside the MD changer is not loaded.

An MD inside the MD changer cannot be played due to

scratches,etc.

A MD inside the MD changer cannot be played because

it is loaded upside-down.

Displayed when a non-recorded MD is loaded in the MD

changer.

Measure

This is a failure of CD changer's mechanism.

Replace with a non-scratched,non-warped

disc.

Eject the disc then reload it properly.

Lower the surrounding temperature and wait

for a while to cool off MD changer.

This is a failure of MD changer's mechanism.

Replace with a non-scratched,non-warped

disc.

Eject the disc then reload it properly.

Load a pre-recorded MD in the MD changer.

Note:

1. For the DVD changer,refer to the service manual provided with the DVD changer.

2. If an error display other than the ones described above appears, press the reset button.

3. When the reset button is pressed,frequencies of TV/radio stations,titles,etc. stored in the memory are cleared.

Содержание pro audio vrx 630

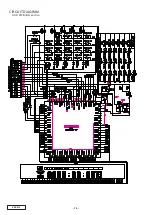

Страница 14: ...DCP PWB B4 section 14 VRX630 CIRCUIT DIAGRAM ...

Страница 15: ...LCD PWB B3 section 15 VRX630 ...

Страница 18: ...Main PWB B1 section 1 2 18 VRX630 CIRCUIT DIAGRAM ...

Страница 22: ...Digital PWB B2 section 1 2 22 VRX630 CIRCUIT DIAGRAM ...

Страница 23: ...Digital PWB B2 section 2 2 23 VRX630 ...