CT-S651 Series Service Manual

- 31 -

2-3. Troubleshooting

Procedure

When a fault occurs, confirm its phenomenon, locate the problem in accordance with “2.2 Troubleshooting

Guide”, and troubleshoot it as described below.

Phenomenon

Find the fault phenomenon in this column. If there are multiple phenomena, take all the applicable

items into consideration. This will help you locate hidden problems as well.

Cause

Possible causes are listed here. Find probable causes from the list and follow the check method to

identify the cause of the fault.

Check Method

The check method for identifying the cause of the fault is described.

Remedies

Take the remedies described in this column.

By following the above-mentioned procedure, you can troubleshoot problems efficiently with fewer

misjudgments.

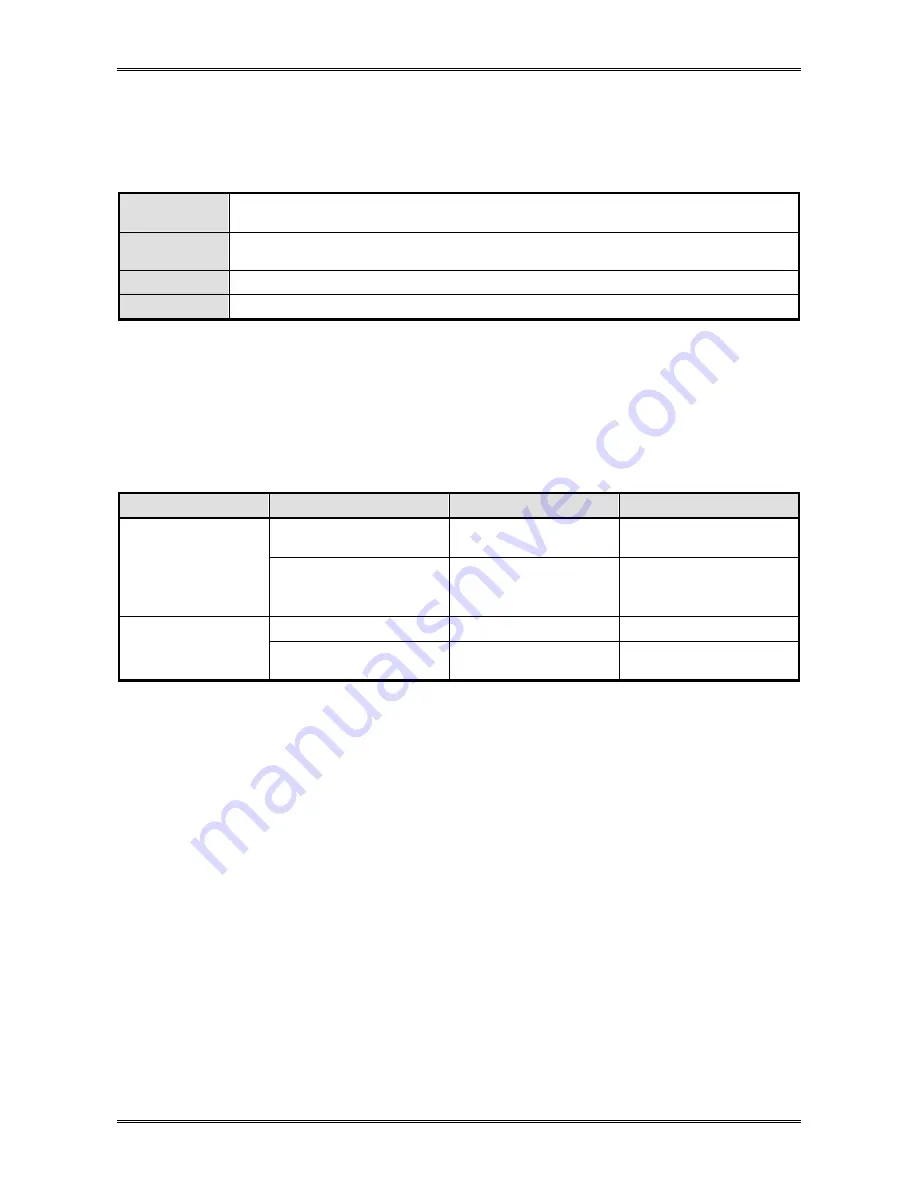

2-4. Troubleshooting

Guide

●

Power Supply Failure

Phenomenon

Cause

Check Method

Remedies

The power cable is not

connected.

−

Connect the power cable.

Power cannot be turned

on.

(The POWER LED not

illuminated.)

The fuse is blown.

Check if the specified fuse is

used.

Use the specified fuse.

The control PCB is faulty.

−

Replace “SA, MAIN PCB”.

The fuse is blown soon if

it is replaced with a new

one.

The circuit drive power is

abnormal.

Use a tester and measure

the circuit drive voltage.

Replace “SA, MAIN PCB”.

* If the fuse is blown with the specified AC adapter used, the thermal head or control PCB may be defective. Replace

the defective part with a new one. Check wiring of the interface cable.

Содержание CT-S651 Series

Страница 1: ...Service Manual COMPACT LINE THERMAL PRINTER CT S651 Series Revision 1 00 2010 3 29...

Страница 2: ......

Страница 50: ...CT S651 Series Service Manual 48 3 2 Parts Layout 3 2 1 SA MAIN PCB...

Страница 51: ...CT S651 Series Service Manual 49...

Страница 52: ...CT S651 Series Service Manual 50 3 2 2 SA OPEPANE PCB 651 3 2 3 SA SERIAL I F PCB...

Страница 53: ...CT S651 Series Service Manual 51 3 2 4 SA PARALLEL I F PCB 3 2 5 SA USB I F PCB...

Страница 54: ...CT S651 Series Service Manual 52 3 2 6 SA USB HUB I F PCB 3 2 7 SA POWERED USB I F PCB...

Страница 55: ...CT S651 Series Service Manual 53 3 2 8 SA ETHERNET E Type I F PCB...

Страница 56: ...CT S651 Series Service Manual 54 4 CIRCUIT DIAGRAMS 4 1 MAIN PCB 4 1 1 Main Control Board CPU1...

Страница 57: ...CT S651 Series Service Manual 55 4 1 2 Main Control Board CPU2 DAC...

Страница 58: ...CT S651 Series Service Manual 56 4 1 3 Main Control Board ROM...

Страница 59: ...CT S651 Series Service Manual 57 4 1 4 Main Control Board RAM...

Страница 60: ...CT S651 Series Service Manual 58 4 1 5 Main Control Board GATE_ARRAY...

Страница 61: ...CT S651 Series Service Manual 59 4 1 6 Main Control Board HEAD OP PANEL...

Страница 62: ...CT S651 Series Service Manual 60 4 1 7 Main Control Board PF MOTOR...

Страница 63: ...CT S651 Series Service Manual 61 4 1 8 Main Control Board SENSOR...

Страница 64: ...CT S651 Series Service Manual 62 4 1 9 Main Control Board POWER DRAWER BUZZER...

Страница 65: ...CT S651 Series Service Manual 63 4 1 10 Main Control Board IF PCB CON OPTION IF...

Страница 66: ...CT S651 Series Service Manual 64 4 1 11 Main Control Board CUTTER...

Страница 67: ...CT S651 Series Service Manual 65 4 2 PE PNE Sensor 4 3 Operation Panel...

Страница 68: ...CT S651 Series Service Manual 66 4 4 Serial I F PCB...

Страница 69: ...CT S651 Series Service Manual 67 4 5 Parallel I F PCB...

Страница 70: ...CT S651 Series Service Manual 68 4 6 USB I F PCB...

Страница 71: ...CT S651 Series Service Manual 69 4 7 USB HUB I F PCB...

Страница 72: ...CT S651 Series Service Manual 70 4 8 POWERED USB I F PCB...

Страница 73: ...CT S651 Series Service Manual 71 4 9 ETHERNET E Type I F PCB 4 9 1 CPU1...

Страница 74: ...CT S651 Series Service Manual 72 4 9 2 CPU2 4 9 3 SD RAM...

Страница 75: ...CT S651 Series Service Manual 73 4 9 4 PHY...

Страница 76: ...CT S651 Series Service Manual 74 4 9 5 I F...