C I R R U S

A I R P L A N E M A I N T E N A N C E M A N U A L

M O D E L S R 2 0

51-20

Page 37

All

EFFECTIVITY:

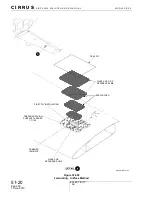

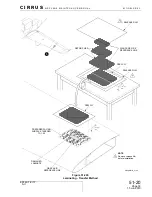

For a repair to achieve full strength, the resin system used in the repair must be properly cured. The

curing processes involves heating the entire repair area using an artificial heat source, namely, a com-

mon hot air dryer. A typical arrangement for hot air dryer enclosure and monitoring system is included

below.

Cure temperatures noted are part temperature not ambient air temperature. During hot air cures, ambi-

ent air temperature should be approximately 15° - 25° F (8.3° - 13.9° C) higher than the desired repair

temperature. However, because the exact ambient air temperature required is dependent on many

factors such as shop temperature, insulation of the enclosure, thickness of the repair, etc., ambient air

temperature can be monitored using a thermometer.

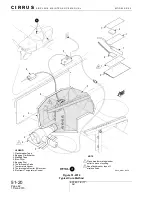

Proper thermocouple placement is crucial for proper high-temperature repairs using portable heating

systems. Most composite parts contain variances in thickness and/or temperature conductivity of the

materials which will create this temperature variation during cure. There may also be heat sinks and

non-uniformity in underlying structure.

If the technician is properly trained and thoroughly familiar with the curing technique, thermal blankets

offer very good control of curing temperature and even distribution of heating. Thermal blankets typi-

cally are made with wires embedded in silicone rubber and can be used at high temperatures. Thermal

blankets must be considerably larger than the area being cured. For example, an 8 inches (200 mm)

diameter circular repair will require at least a 12 inches (300 mm) diameter heat blanket. Using this

size of blanket allows for thermocouple placement well inside the blanket edges.

When thermal blankets are used, multiple thermocouples are required. This is because thermocouple

failures are common and replacement during a running cure is virtually impossible. Also, temperatures

can easily vary widely across a repair area during cure: 60 - 80ºF (35 - 45ºC) spreads are not uncom-

mon.

Other curing techniques such as vacuum bagging and ovens may also be used if available and the

technician is properly trained and thoroughly familiar with the curing technique.

For repairs performed to sandwich structure, it is often difficult to properly heat the inner laminate com-

pletely and is therefore necessary to perform two post-cure cycles. This is accomplished by repairing

the structure in two phases; the inner laminate is repaired and fully cured then the core and outer lam-

inate are repaired and a complete cure cycle is performed.

Part temperature should be raised at a rate of 1.0° - 5.0° F (0.6° - 2.8° C) per minute. Part temperature

should be lowered at a rate of 1.0° - 15.0° F (0.6° - 8.4° C) per minute. Bringing the part temperature

up slowly is preferred as this allows the resin to solidify at a lower temperature. During the first part of

the cure cycle the repair plies should be observed frequently. Any air trapped within the repair will

expand when heat is applied. Before the resin solidifies, it is important to lance any bubbles that form

with a scribe or pin, and push the ply down with a brush.

Multi-step post-cures may be used providing the total time at temperature meets the minimum require-

ment.

Note:

A multi-step post cure may be used providing the total time at temperature meets the

minimum requirement. Initial cure requirements must be met if assembly will be handled

between post cure steps

CAUTION:

Room temperature cures of MGS L418/H418 and MGS L285/H287 are not allowed.

These structural resin repair systems will not cure to a suitable condition at room tem-

peratures.

Do not allow part temperature to exceed 210° F (93° C) and do not allow ambient air

temperature to exceed 205° F (96° C).

15 Jun 2010