Einbau- und Betriebsanleitung

Installation and Operating instructions

Instructions de montage et de service

6139-8010

07/2018

9

Troubleshooting

9.2

Position regulator

doesn’t respond to the input signal

.

9.2.1

Check the supply pressure level, which must be at least 1.4 bar. On drives with return springs the pressure must be higher than

the total spring force.

9.2.2

Return springs - verify the input signal is routed correctly on the position regulator. The signal should be 4-20 mA DC.

9.2.3

Verify the zero point and stroke range are correctly set.

9.2.4

Check the jet on the position regulator for blockages. Also verify the compressed air is in contact with the regulator and air is

being emitted from the jet. If the jet was blocked please return the product for repair.

9.2.5

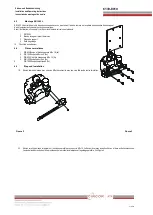

Verify the lever is installed correctly.

9.3

Pressure at the OUT1

output reaches the output pressure but doesn’t drop

.

9.3.1

Check the A/M switch. If the switch is damaged replace the switch or install a relay.

9.3.2

Check the space between the armature shaft and jet and check the mechanism for damage. If damaged, please send the

product to Regeltechnik Kornwestheim for repair.

9.4

Air only escapes from the A/M switch.

9.4.1

Check the regulator jet for blockages. Verify the compressed air is in contact with the regulator and compressed air is being

emitted from the jet. If the jet is blocked please return the product for repair.

9.5

Swinging regulator

9.5.1

Check if the locking spring is dislocated. (Next to the pilot relay valve).

9.5.2

Check if the drive is too small. If so, install a cover to reduce the flow rate.

9.5.3

Check for excessive friction between the drive and the valve. If so, install a larger drive or reduce the friction level.

9.6

The drive will only operate on On/Off.

9.6.1

Check the functionality of the drive and regulator. On the SR 1000 L compressed air will escape from output OUT1 as the input

signal increases. Thus it is standard practice to connect to output OUT1 when using a single-acting drive. Verify the stroke

width is correctly set according to the valve system.

9.7

Linearity too low.

9.7.1

Check if the regulator is installed correctly. Particularly verify the lever is horizontal at 50% stroke.

9.7.2

Verify the zero point and stroke width are set correctly. If a value is adjusted the other must be readjusted.

9.7.3

Verify the compressed air supply is solid. If not, replace the compressed air regulator.

9.8

Hysteresis too low.

9.8.1

Clearance may exist if the lever and the spiral spring are loose. To avoid clearance, adjust the spiral spring.

9.8.2

Verify if the actuating pin is connected to the lever without clearance.

1 Identification du produit