CI-340 Operation Manual rev. 6/7/2017

CID Bio-Science

1554 NE 3

rd

Ave

Camas, WA 98607, USA

Phone: +1 (360) 833-8835

Fax: +1 (360) 833-1914

[email protected]

www.cid-inc.com

3

Technical Information

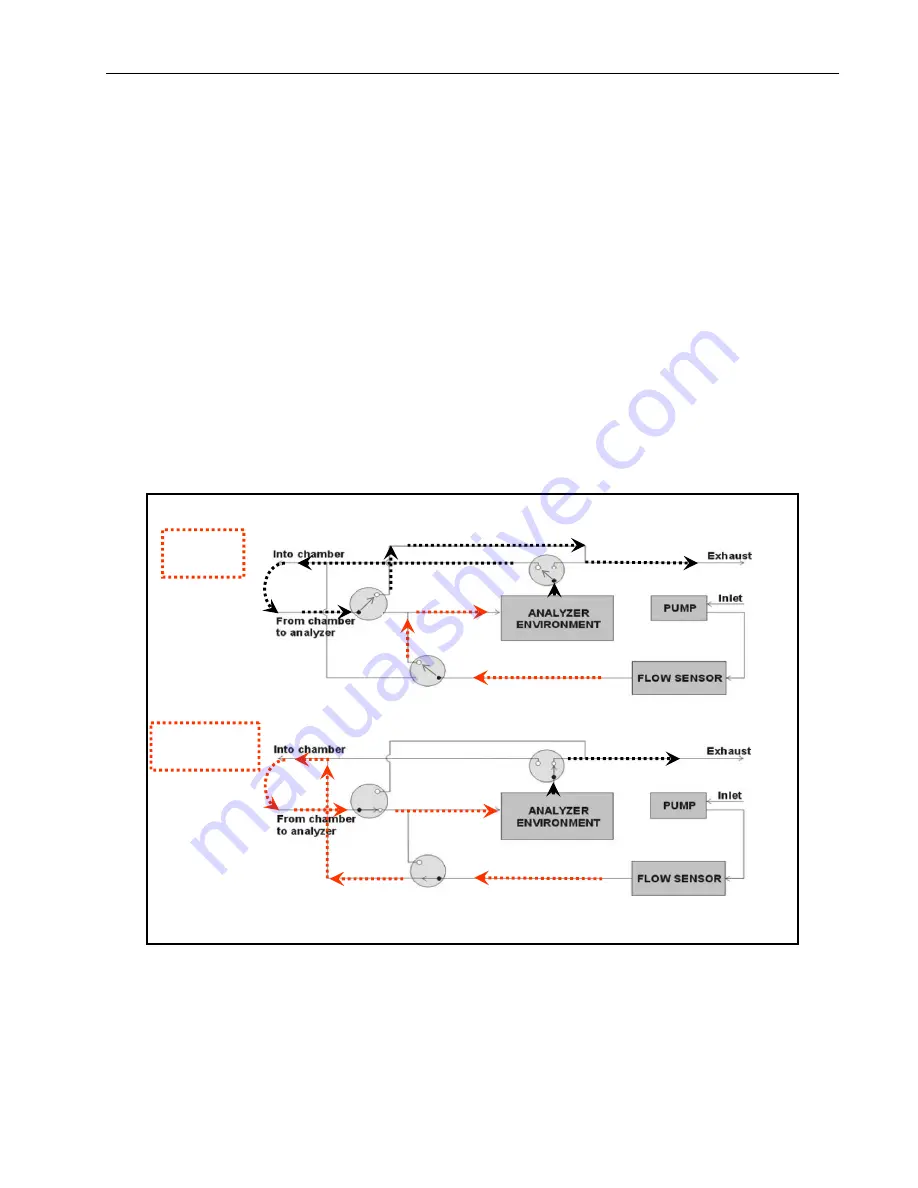

The CI-340 is a highly technologically advanced photosynthesis system. It contains a pump along with a

mass airflow sensor. A built-in microprocessor regulates the airflow rate, which is set by the user.

Specifically, the CI-340 is a non-dispersive IRGA in which the infrared light is shone through the gas in

the sampling chamber and then focused on a detector. The energy received at the detector is the total

energy entering the system minus the energy absorbed by the CO

2

in the sampling chamber. A

technical diagram (Figure 1) illustrates a flow chart for this instrument. An illustration of the CI-340

can be found in Figure 2.

The measurement process starts with the gas or air sample passing a solid-state CO

2

analyzer. The

output of the analyzer is amplified, sampled by an analog-to-digital (A-D) converter, and sent to the

microprocessor. The processor averages these readings and corrects them for any non-linearity

present in the analyzer. A relative value of CO

2

concentration is continually updated by the

microprocessor. Each reading reflects a sample being taken every second during a specified time

period. This can be determined by setting the time interval. The rate at which samples are saved in

memory is determined by the “sampling rate” or the time interval input at the beginning of each

measurement session. If you listen carefully during analysis, you can hear the valves switching from

reading the “in” values to the “out” values and the sample number or count will increase by one.

Inlet

Outlet

Figure 1: The pathway of airflow through the CI-340 during measurement. The top figure illustrates

the valve placement and air flow during an “in” reading and the lower

figure illustrates the valve

placement and air flow during and “out” reading.

Содержание CI-340

Страница 3: ......