7 - LGN UNIT CONNECTIONS

7.1 - Recommendations for the installation

of liquid chillers with remote condenser.

LGN units (split units to connect to air-cooled condensers) have

been specially designed to optimise the operation of split

installations using air-cooled condensers as a cooler heat

rejection system.

The cooling installation of an operational system is therefore

limited to connect the LGN unit air-cooled condenser inlet and

outlet.

Components such as the check valve (on the discharge line),

liquid sight glass, solenoid valves are fitted and factory wired.

The drier is provided with the unit and must be installed upstream

of the solenoid valve on the liquid line

The Pro- LGN control integrates logics allowing the

different fixed and variable speed fan variants to be controlled.

To ensure optimum and reliable performance of the units, it is

necessary to respect several regulations mentioned below when

these machines are connected to remote condensers:

-

Size the discharge and liquid line pipes according to the

recommendations in the following paragraphs (if required,

install a double riser column to ensure correct oil circulation

in the refrigerant circuit).

-

Select a condenser with an integrated subcooler to obtain a

minimum of 3 K subcooling at the expansion valve inlet.

-

Install the drier provided with the unit as close as possible to

the liquid line drier

-

Install the outside air temperature sensor provided near the

air-cooled condenser. For units with remote condenser control

(option 154), the sensor is provided. The outside air

temperature is vital in order for the entire system to run

smoothly.

For remote air-cooled condenser control (option 154):

-

Connect the fan stages electrically on the control panel using

the auxiliary electronic board "AUX 1". Refer to chapters 14

and 15 for the description of the analogue and discrete inputs

and outputs for assigning fan stages.

-

Make the communication BUS (twisted and shielded BUS

type communication cable RS485) between the specific

electronic AUX 1 board, that must be integrated in the

condenser control box, and the NRCP master board of the

Dynaciat LG unit.

-

Configuration in Pro- the number of fan stages and

fan type based on the air-cooled condenser used in the

installation. Use of a variable speed drive on the first fan stage

is recommended for low ambient temperatures at partial load

and for condensers with few fans.

It is essential to select an air-cooled condenser with

a subcooler. Generally, 8°C of subcooling is

recommended at the condenser outlet.

7.2 - Pipe routing and connection

On all units release the holding charge pressure before opening

the circuit.

Use different valves and/or remove the safety cap provided from

the conical Schraeder connections, press on the valve tip to

release all the standby charge in the system (nitrogen).

Preparation before debrazing the liquid and discharge plugs:

-

Remove all components that may be damaged during

debrazing procedures

-

Braze the pipes: Remove the conical Schrader connections

near the area, remove the pipe collars, remove the casing

panels and the metal crossbars.

-

These components must be replaced before start-up of the

system.

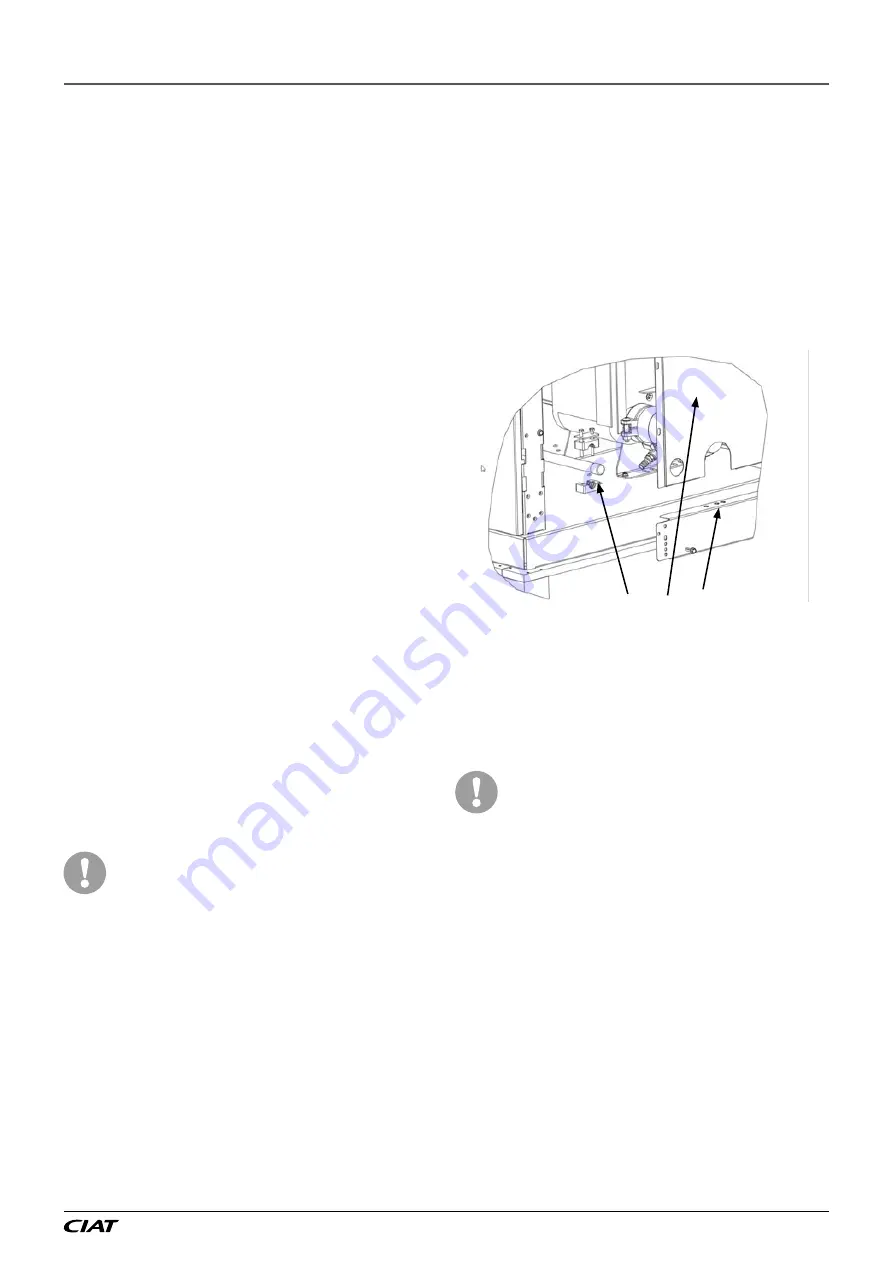

Components to remove for brazing

Unweld the caps and prepare the tubes for connection.

Connect the liquid line to the system, fit the drier upstream of

the unit

Make the high-pressure connections (discharge line) between

the unit and the condenser.

During these operations, allow an inert gas such as nitrogen to

circulate in the ducts to prevent the formation of copper oxide.

The condenser circuit routing must primarily

respect industry practices concerning the static

support and the thermal expansion of copper pipes.

To control vibration in the system, the collar

positions on the machine pipes must not be

changed. Clamps for securing the pipes are

provided at the refrigeration unit outlet. It is

essential that these clamps are tightened to prevent

vibrations and potential ruptures.

The pipes between the unit and the condenser must

be correctly supported, according to their size and

their operating weight. The pipes must be supported

in order to ensure that the vibration levels on the

pipes is lower than the existing values on the

compressor. If resonance occurs, reduce the range

between the collar until the vibration levels are

acceptable.

EN-39

Dynaciat LG/LGN

Содержание DYNACIAT LG 080

Страница 1: ...DYNACIAT LG LGN 07 2018 10188 Instruction manual...

Страница 2: ...Dynaciat LG LGN EN 2...

Страница 3: ...EN 3 Dynaciat LG LGN...

Страница 67: ...EN 67 Dynaciat LG LGN...