561105-10 en ma 2012.10

15/22

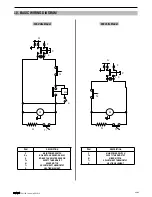

Fig. 34 shows a seal which is not correctly assembled; here the seal does NOT

perfectly adhere to the bowl edge.

5-liter and 10-liter models: (1.32 and 2.64 Gal US):

• fi t the bowl back into place, pushing fi rmly downward, after moistening the

seal with water;

DO NOT USE GREASE OR VASELINE.

Warning: make sure that the bowl is correctly fitted to the ma-

chine; an incorrectly fitted bowl will cause the product to leak

out; risk of scalding!

Fig. 36 shows a bowl correctly assembled; here the bowl perfectly adhere to

the machine edge.

7.7. Washing and sanitizing the components

All of the component parts previously disassembled (tap, mixer, mixing auger,

gasket and bowl) must be carefully washed and sanitised.

To carry out this procedure correctly proceed as follows:

• fill a container with detergent and hot water with a temperature of 50-60°C

(122-140°F);

• wash the disassembled components with the detergent solution;

• rinse with hot water;

• clean only with warm water and a sanitising product made from sodium

hypochlorite diluted in water to obtain an active chloride concentration of

0.02%;

• immerse the disassembled component parts in the sanitising solution;

• leave the components inside the container of sanitising solution for about 30

minutes;

• rinse with clean water;

• clean the bowl lid,

(see paragraph 7.11);

• place the components on a clean surface and dry them.

7.8. Assembling the washed components.

All washed and sanitised component parts must be re-assembled with care and

then subsequently refitted to the machine, following the relevant steps.

7.8.1. Assembling the bowl

Warning: make sure that the gasket is correctly fitted; an incor-

rectly fitted gasket will cause the product to leak out; risk of

scalding!

Before assembling the bowl in the machine, check that the seal is correctly

assembled.

Fig. 33 shows a seal correctly assembled; here the seal perfectly adheres to

the bowl edge.

Fig. 33

OK!

NO!

Fig. 34

Fig. 35

Fig. 36