Rated control supply voltage Us(V)

Operating voltage (V)

Power dissipation (W)

Energy storage time

Frequency of operation

Rated voltage(V)

AC

300VA

DC

60W

230

400

220

AC230 AC400

(0.85~1.1)Us

75/150VA

<

4s

At most 3 times in a minute

Rated thermal current Ith(A)

DC220 DC110

75/150W

Rated control capacity

6

(Inm=1600A)

(Inm=3200A,

)

6300A

6

(Inm=3200A,

)

6300A

(Inm=1600A)

9. Installation

10. Common faults and troubleshooting

2

No.

1

Breaker fails

to close

Technical problems

Breaker tripping

(fault indicator on)

Earthing fault tripping

(earthing fault indicator on)

Under voltage release

Tripping

Mechanical interlock action

Under voltage release

No attracting

Reset button fails to reset

Open frame (draw-out) circuit

breaker fails to be put to the righ

t position by rocking

Open frame (draw-out) circuit breaker

Bad contact for the secondary circuit

Breaker fails to pre-store energy

Overload fault tripping

(long time delay indicator on)

Short-circuit fault tripping

(short time-delay or

instantaneous overcurrent

indicator on)

Possible causes

1 Check the breaking current and operating time on the intelligent controller

2 Promptly find and shoot the trouble if it is confirmed that there is a earthing fault

3 If no earthing fault is detected, please determine whether the earthing fault

current setting is proper, and can be well matched with the actual protection;

if not, the setting shall be modified

4 Press the reset button to close the breaker again

1 Check to see if the power voltage is lower than 70%Ue

2 Check the under voltage release and control unit for fault

Check the working condition of two breakers equipped with mechanical interlock.

Diagnosis and trouble shooting

1 Check the breaking current and operating time on the intelligent controller

2 Analyze the operation of the load and power network

3 Promptly find and shoot the trouble if overload is confirmed

4 For lack of match between the actual running current and the long time delay

operating current, please modify the long time-delay operating current setting

for a proper match and protection according to the actual running current

5 Press the reset button to close the breaker again

1 Check the breaking current and operating time on the intelligent controlle

2 Promptly find and shoot the trouble if overload is confirmed

3 Check the setting value of the intelligentcontroller

4 Check to see whether the breaker is in good condition, and determine whether

it can be closed for operation

5 Press the reset button to close the breaker again

Closing electromagnet trouble

1 Whether the under voltage release has been energized

2 Whether the power voltage is lower than 85%Ue

3 Whether the under voltage release or control unit malfunctions,

if so, the release shall be replaced.

Press the reset button to close the breaker again.

Put the open frame (draw-out) circuit breaker to the right position

by rocking (with it locked in the connected position)

Check the contract status of the secondary circuit,

and shoot the trouble, if any

1 Check the motor control power supply and see if it is well

providing power, and the voltage must be

≥

85%Us

2 Check the status of the motor energy storage mechanism.

1 Check the power voltage of the closing electromagnet,

and it must be higher than or equal to 85%Us

2 If there is any trouble in the closing electromagnet to enable the attracting,

it shall be replaced.

NA8G

Air Circuit Breaker

P-036

P-035

NA8G

Air Circuit Breaker

9.1

Following

items

to

be

checked

before

installation

Check

the

label

plate

on

the

breaker

panel

to

see

if

it

is

conform

to

the

specifications

of

the

ordered

goods

.

a

.

Rated

current

b

.

Under

voltage

release

voltage

and

delay

time

c

.

Shunt

release

voltage

d

.

Closing

electromagnet

voltage

e

.

Motor

voltage

9.2

Before

installation

,

operation

,

maintenance

and

inspection

,

you

shall

read

this

manual

,

and

consult

the

manufacturer

for

questions

,

if

any

.

9.3

Preparations

before

installation

Before

the

breaker

is

installed

,

check

the

insulation

resistance

of

the

breaker

by

using

a

1000

V

megohmmeter

according

to

regulations

;

when

the

surrounding

media

temperature

is

25℃±5℃

and

the

relative

humidity

50% - 70%,

the

insulation

resistance

shall

not

be

less

than

20

megohm

.

The

place

with

the

insulation

resistance

to

be

tested

includes

:

the

place

between

various

phases

and

between

various

phases

and

the

frame

when

the

breaker

is

closed

;

the

place

between

in

-

and

out

-

lines

of

various

phases

.

Listed below are the problems which users may encounter

during installation, adjustment, and operation of the breaker,

and the possible reasons and elimination methods.

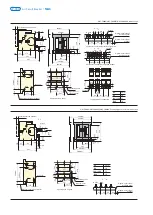

9.4 Installation of the fixed type breaker

Place the breaker into the distribution cabinet, and fasten it

by using 4 pieces of M6(In=1600A) or M10(In=3200A or

more) bolts and washers. The breaker shall be installed stably

with no additional mechanical stress to avoid damage of the

breaker or bad contact of the main bus bar.

9.5 Installation of the open frame (draw-out) circuit breaker Take

the breaker body out of the draw-out socket, and install the

socket in the distribution cabinet, and fasten it by using 4

pieces of M6(In=1600A) or M10(In=3200A or more) bolts and

washers; the breaker shall be installed stably with no

additional mechanical stress to avoid damage of the breaker

or bad contact of the main bus bar. After the work is

completed, mount the body into the draw-out socket.

9.6 The specifications of the wiring copper bars for the primary

circuit of the breaker shall meet the copper bar specifications

used under the conditions of conventional heating in IEC/EN

60947-2.

9.7 The breaker shall be grounded substantially.

8.4 Motor-driven energy storage mechanism

The functions of motor-driven energy storage and automatic energy

re-storage after the breaker comes on are available to ensure that

the breaker can come on immediately after it gets

8.6 Phases barrier

Phases barrier is installed between the phases of the line bank to improve the

insulating ability between the phases of the breaker

.

8.7 Key lock

The OFF pushbutton of the breaker can be locked in the position of depress,

and at this time, the breaker cannot be closed for operation; When the user

selects the option, the factory provides locks and keys; One breaker is provided

with one lock and one key for the lock; Two breakers are two provided with

locks and one key for the locks; Three breakers are provided with three same

locks and two same keys for the locks.

Note:

For the air circuit breaker with key lock, when the key has to be pulled out, it is

necessary to first press the OFF key, turn the key anticlockwise, and then pull

out the key.

8.8 Button locking device

It is used to lock the button for opening and closing the breaker with the

padlock used for such a purpose. (Padlock is provided by users themselves)

8.9 Doorcase

They are installed on the door of the distribution cabinet room to seal it with a

protection level of up to IP40.

8.10 “Disconnected” pation locking device for the draw-out.

For the “separation” position of the open frame (draw-out) circuit breaker, a

lock rod can be pulled out to lock the matter, and the breaker locked will be

unable to be turned towards the TEST or CONNECTION position. Padlocks

have to be provided by users themselves.

8.11 Three-position locking device for the draw-out.

After the breaker body is locked automatically in any working position, it is

necessary to turn the key to unlock the matter so that the break body can be

moved to the next working position by turning the handle. (this function

available for 3200 to 6300).

8.12 Door interlock

Door interlock for the breaker status

When the breaker is closed, the cabinet door must not be opened; when the

breaker is switched off, the cabinet door is allowed to be opened. Door

interlock for the breaker position When the breaker is in the position of

connection and test, the cabinet door must not be opened; when the breaker

is the separation position, the cabinet door is allowed to be opened.

8.13 Mechanical interlock

It can realize the interlock of two horizontal or vertical-installed,three poles or

four poles,drawout or fixed breakers.

8.5 Auxiliary contact

Standard type:4 switch contact

Special type:5 switch contact

6 switch contact (Only for I =1600A, and not available for DC)

nm

3 N.O. and 3 N.C.

4 N.O. and 4 N.C.(I =3200A and 6300A provided)

nm

disconnected.Operating characteristic:

Technical parameters:

Содержание NA1

Страница 1: ...Air Circuit Breaker Leading every step reliable new height ...

Страница 2: ...Air Circuit Breaker Leading every step reliable new height ...

Страница 3: ......

Страница 4: ...Page P 001 Page P 039 ACB Air Circuit Breaker NA8G NA1 ...

Страница 45: ...P 041 NA1 Air Circuit Breaker 1 3 4 5 7 8 11 12 13 14 15 ...