EM12-SP User Manual

5. Description of Function Code

21

The acceleration/deceleration time indicates the time for the frequency inverter to increase from 0 Hz to the

frequency set in

F0-25

,

figure

6-1

is the acceleration/deceleration time diagram.

If this parameter is set to 1, the acceleration/deceleration time is related to the set frequency. If the set frequency

changes frequently, the motor's acceleration/deceleration also changes.

Pay attention for this in on-site application.

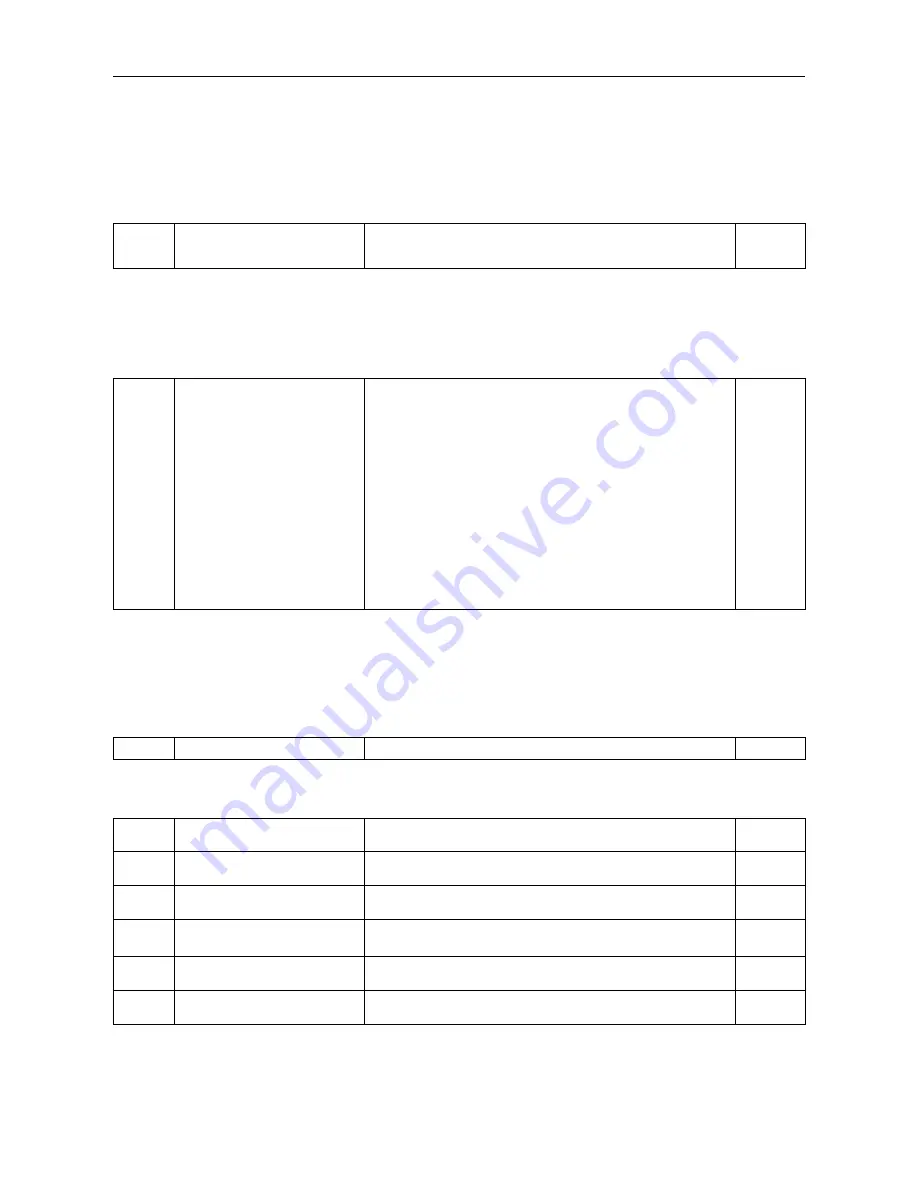

F0-26

Base frequency for UP/ DOWN

modification during running

0: Running frequency

1: Setting frequency

0

This parameter is valid only when the frequency source is digital setting.

It is used to set the base frequency to be modified by using keys

▲

and

▼

or the terminal UP/DOWN function.If the

running frequency and setting frequency are different, there will be a large difference between the frequency

inverter's performance during the acceleration/ deceleration process.

F0-27

Binding command source to

frequency source

Unit's digit: Binding keypad command to following frequency

source.

0: No binding

1: Frequency source by digital settin

2: AI1

3: AI2

4: AI3

9: Communication setting

Ten's digit: Binding terminal command to frequency source.

Hundred's digit: Binding communication command to frequency

source.

0000

It is used to bind the three running command sources with the nine frequency sources, facilitating to implement

synchronous switchover.

For details on the frequency sources, see the description of

F0-03

(Main frequency source X selection).Different

running command sources can be bound to the same frequency source.

If a command source has bound to a frequency source, this frequency source set in

,

F0-03~F0-07

no longer takes

effect when this command source is effective.

F0-28

Serial communication protocol 0: Protocol MODBUS-RTU

0

The use of EM12-SP serial port communication protocol MODBUS.

F1 Motor Parameter

F1-00 Motor type selection

0: General asynchronous motor

1: Variable frequency asynchronous motor

0

F1-01 Rated motor power

0.1kW

~

1000.0kW

Model

dependent

F1-02 Rated motor voltage

1V

~

2000V

Model

dependent

F1-03 Rated motor current

0.01A

~

655.35A(Frequency inverter power

≤55kW

)

0.1A

~

6553.5A(Frequency inverter power >55kW)

Model

dependent

F1-04 Rated motor frequency

0.01Hz

~

maximum frequency

Model

dependent

F1-05 Rated motor rotational speed

1rpm

~

65535rpm

Model

dependent

Set the parameters according to the motor nameplate no matter whether V/F control or vector control is adopted.

To achieve better V/F or vector control performance, motor auto-tuning is required. The motor auto-tuning

accuracy depends on the correct setting of motor nameplate parameters.