Chiltrix Inc.

39

Timer 1 Start time and Days of the week selected (TU and WE),

timers 1-4 use the same menu

Administrator Functions

Click

“Administrator”

button, you need to enter the password

“2222” to enter the “P” parameters setting page as shown below.

Refer to “P” parameter section for parameter list. Example below.

NOTE: Any changes to P59 or P61 require a 15-second reboot at the

circuit breaker panel or Disconnect

Содержание CX34-4

Страница 4: ...Chiltrix Inc www chiltrix com CX34 Components 4 ...

Страница 18: ...Chiltrix Inc www chiltrix com Electric Connections and Component Locator 18 ...

Страница 19: ...Chiltrix Inc www chiltrix com CX34 System Wiring Diagram 19 ...

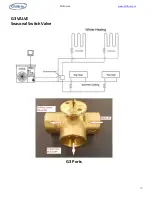

Страница 25: ...Chiltrix Inc www chiltrix com G3 VALVE Seasonal Switch Valve G3 Ports 25 ...

Страница 34: ...Chiltrix Inc www chiltrix com 34 Language Screen Screen Saver ...

Страница 35: ...Chiltrix Inc www chiltrix com 35 Touch Screen Fixing Calibration Time Setting ...

Страница 52: ...Chiltrix Inc www chiltrix com 52 ...

Страница 53: ...Chiltrix Inc www chiltrix com 53 ...

Страница 54: ...Chiltrix Inc www chiltrix com 54 Chiltrix CX34 Internal Pump Wilo Yonos PARA RS 25 7 5 PWM1 Ku ...