Chiltrix Inc.

Purging Air From DHW Tank & Fan Coils

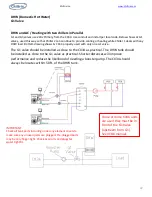

If a DHW tank is installed, it should be the first device on the loop as shown. The G1 valves should

always be as close to the CX34 as possible. The tank should be as close to the G1 valve as possible.

To purge the air from its coil, remove the actuator from the valve body and rotate the valve stub 90°

clockwise to force the water through the coil. Return the valve stub back to its original position

when all of the air is purged. Close the input valve to each fan coil except the first coil (1). Turn the

pump on and run it, when the bubbles stop coming out of the discharge hose turn on the ball valve

on coil (2), wait for the bubbles to stop, then do the same for coil number (3), then (4). All CX

Chillers have a flow switch installed in the loop. Air in the system may cause a flow switch alarm; the

controller will display a P05 error code.

All CXI fan coils have an air purge screw near the water inlet port, always purge the fan coils before

starting the chiller. The CX34 chiller also has a bleeder valve with a ¼” clear tube attached to it

located near the brazed plate heat exchanger.

Fan Coil Flow Balancing (Performed at time of commissioning)

Proper and even flow through each fan coil is important for both heating and cooling. , (Coil

temperature can be displayed by pressing the up and down temperature arrow keys at the same

time), This can be done with balancing valves or ball valves installed at each fan coil supply or return

pipe. This must be done with the CX34 in heating mode, set loop AC target to the maximum temp

setting for commissioning.

DO NOT DO THIS IN COOLING MODE OR DAMAGE MAY OCCUR.

Adjust valve positions until each fan coil has the same leaving fluid temperature, with all CXIs set to

max manual fan speed and in heating mode. When all leaving fluid temps are the same, the units

are properly balanced. If a fan coil is powered on but the fan isn’t running, there is a good possibility

that there is air trapped in that particular part of the loop. Also verify the parameters with the CXI

FCU manual, page 34.

http://www.chiltrix.com/documents/Chiltrix-hydronic-FCU-ver-1.5.pdf

Note – while only one ball valve per CXI is needed for balancing, best-practice would be to use 2

valves, one on supply and one on return, so that the fan coil unit could be isolated if needed.

30

Содержание CX34-4

Страница 4: ...Chiltrix Inc www chiltrix com CX34 Components 4 ...

Страница 18: ...Chiltrix Inc www chiltrix com Electric Connections and Component Locator 18 ...

Страница 19: ...Chiltrix Inc www chiltrix com CX34 System Wiring Diagram 19 ...

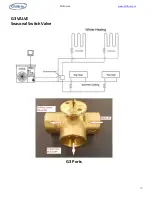

Страница 25: ...Chiltrix Inc www chiltrix com G3 VALVE Seasonal Switch Valve G3 Ports 25 ...

Страница 34: ...Chiltrix Inc www chiltrix com 34 Language Screen Screen Saver ...

Страница 35: ...Chiltrix Inc www chiltrix com 35 Touch Screen Fixing Calibration Time Setting ...

Страница 52: ...Chiltrix Inc www chiltrix com 52 ...

Страница 53: ...Chiltrix Inc www chiltrix com 53 ...

Страница 54: ...Chiltrix Inc www chiltrix com 54 Chiltrix CX34 Internal Pump Wilo Yonos PARA RS 25 7 5 PWM1 Ku ...