Page 10

For equipment technical questions, please call 1-888-866-5797.

For engine technical questions, please call 1-800-520-0882.

ITEM 61924

SAFETY

SETUP

O

PERA

TION

M

AINTENANCE

Break-in Period:

a. Breaking-in the engine will help to ensure

proper equipment and engine operation.

b. The operational break-in period will last

about 3 hours of use. During this period:

• Do not apply a heavy load to the equipment.

• Do not operate the engine at

its maximum speed.

c. The maintenance break-in period

will last about 20 hours of use.

• Change the engine fuel/oil

mixture after this period.

Under normal operating conditions subsequent

maintenance follows the schedule explained

in the MAINTENANCE section.

General Operating Instructions

TO PREVENT SERIOUS INJURY:

Wear ANSI-approved safety goggles, ear protection, steel-toe boots, and dust mask during use.

Keep feet clear of Breaker Hammer.

Keep children and animals well clear of the work area.

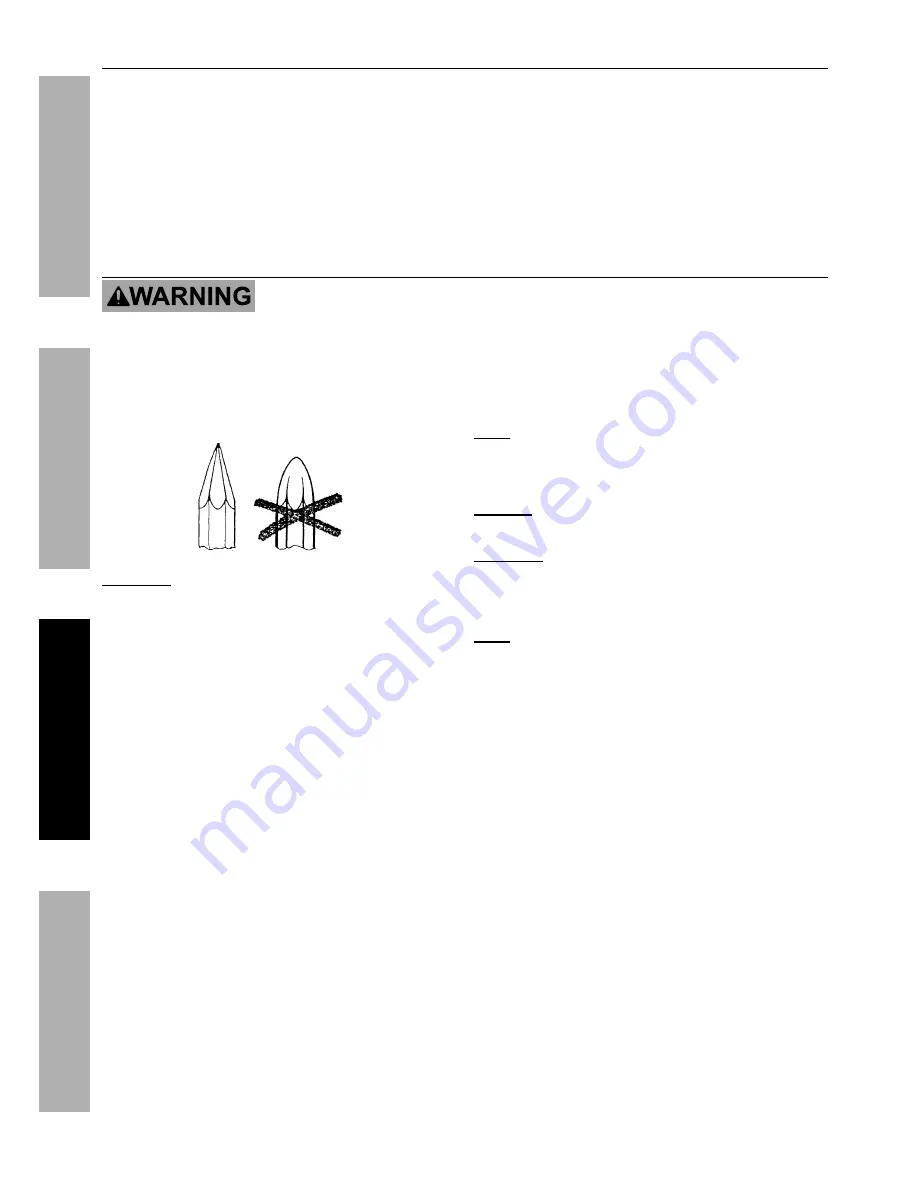

1. Check Chisel for dullness, cracks, or other

damage. Sharpen or replace if necessary.

CAUTION!

Dull tipped chisels can cause unnecessary

chisel movement, resulting in tool wear and

possible injury. Use only sharp tipped chisels.

2. Clearly mark the work area.

3. Start the Engine as detailed in

Starting

the Engine

on page 8.

4. Grip the Handlebar of the

Breaker Hammer with both hands.

5. Set the bit against the work area.

6. Press down on the Throttle.

Note:

Throttle does not lock. Keep pressure

on the Throttle to keep running the tool.

7. Push the tool down to begin striking material.

NOTICE:

Running tool with no load or “empty

blows” will damage the Breaker Hammer.

CAUTION!

Once activated, do not press,

bear down, or thrust forcibly against the work

surface. Allow the Breaker Hammer’s own

weight to supply the needed force.

Note:

If the Breaker Hammer has not been used for

a long time or is being used in low temperatures,

the tool may require 3-5 minutes to warm up.

8. When work is complete, release the

Throttle and shut off the Engine. Refer to

Stopping the Engine

on page 11.

9. Clean, then store the tool indoors

out of children’s reach.