TROUBLE SHOOTING

PROBLEM

PROBABLE CAUSE

SOLUTION

Planer will not start

Not plugged in

Plug in.

Fuse or circuit blown

Replace fuse or reset circuit

Socket

Test socket with current tester

of try another tool in socket.

If socket does not function

properly, have it replaced by a

qualified technician.

Worn brushes

Replace Brushes.

Damaged cord of plug

Have cord replaced by a

qualified technician.

Switch not working

Have switch replaced by a

qualified technician.

Motor not working

Contact Harbor Freight Tools

for servicing.

Planer starts, but cutterhead

Worn or broken belt

Replace belt.

does not move

Planer starts, cutterhead moves,

Blade not extended beyond foot

Adjust for more cutting

but wood remains uncut

depth.

Belt worn and slipping

Replace belt.

Operation interrupted

Forcing Unit

Apply less pressure.

Overloaded circuit

Use on an isolated circuit.

Check for adequate amp rating

and, if necessary, install proper

fuses/breaker to allow for

sufficient amperage.

Rough/fuzzy grain

Blade setting too deep

Reduce depth setting and use

more passes.

High moisture content

Dry wood before planing.

Grain is torn grain

Blade setting too deep

Reduce depth setting and use

more passes.

Dull cutter blades

Replace blades.

Page 11 -- SKU: 32222

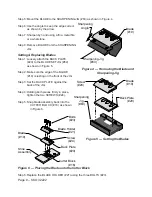

Содержание 32222

Страница 13: ...EXPLODED VIEW DRAWING Page 13 SKU 32222 ...