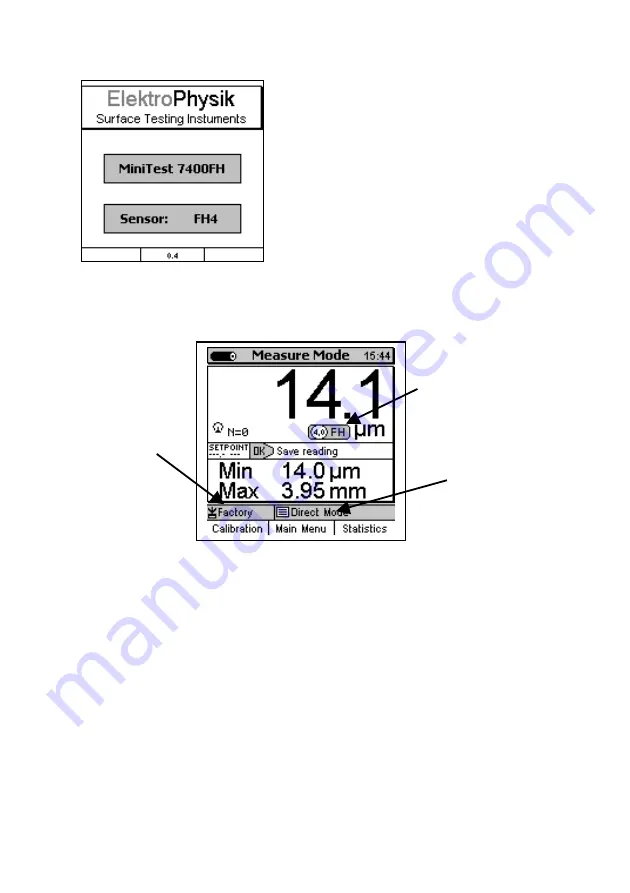

a) Start Screen appears showing company

logo, gauge version and sensor type that is

currently connected (see illustr. on the left.)

b) After approx. 2 seconds, the gauge switches

automatically into measure mode and is

ready to take readings. The Measure

Screen will appear without any reading

being shown.

c)

At initial switch-on the gauge is in “Direct

Mode“. For this mode, the factory calibration

is preset. Please check whether the target

ball size as adjusted matches your

application.

a) The factory calibration is for quick and easy measurement when larger

measuring errors are acceptable. For other calibration methods please refer to

section 6.2.

b) For measurement, please use the sensor stand supplied with the gauge. Place

the measuring object on the sensor. Place the target ball on the opposite side.

For measuring hollow parts, place the ball inside the sample. Equipped with a

strong permanent magnet, the sensor attracts the target ball and holds it

exactly over its sensor tip. Hold the measuring object in rectangular position to

the sensor and move it smoothly over the sensor. Press OK to store the

reading into memory. Press Function key “Statistics” to view readings and the

numerical statistics.

For measuring large-sized sheeting material or large hollow parts, place the

sensor on the surface of sample. The target ball is placed on the opposite side

near the sensor. Keep the sensor in rectangular position to the surface and

move it across the surface of sample.

Target ball size

current setting: 4.0

mm dia.

Calibration mode

Current setting:

Factory calibration

Current measuring series:

„Direct Mode“