GENERAL INFORMATION - A-13

79019435B

FIG. 8

I-5485

FIG. 9

I-5486

FIG. 10

I-5487

1

1

Snap rings

Snap ring installers should be designed so as not to per-

manently deform the snap rings, 1.

Installed snap rings should be seated securely in the

groove.

Be careful not to overload the snap ring to the extent that

it is permanently deformed.

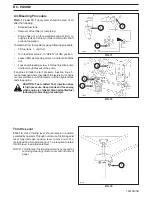

FIG. 8: How to install the snap ring:

When installing a snap ring, install it as shown in the

figure with its round edge turned toward the part to be

retained. This round edge is formed when the snap ring is

pressed out.

Spring (roll) pin

FIG. 9: Spring pins should fit tightly.

Spring pins should be installed so that their seams face

the direction from which the load is applied.

The roll pins installed in the transmission or other parts

where much force is applied should be retained with wire.

Cotter pins

FIG. 10: When installed, cotter pins should be bent se-

curely at the ends as shown in the figure.