11

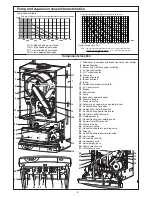

REMOVAL AND REPLACEMENT OF PARTS

Before removing appliance case, isolate

the gas and electrical supplies. Isolate

boiler from the system and drain before

removing any component in the water-

ways. Ensure that the appliance is cool.

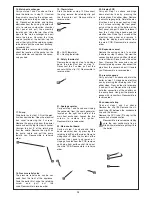

1. Outer Case

Remove four screws in base of case and

lift free. When replacing, carefully locate

on lugs

T on top edge of chassis.

2. Sealed chamber front panel

Unscrew four self taping screws secur-

ing the sealed chamber front panel and

lift over top corner locating lugs.

Reassemble in reverse order.

3. Combustion Chamber front panel

and air/gas connection

Carry out step 1 and 2 as above.

Unscrew three screws securing the

air/gas connection pipe onto the gas

valve assembly. Disconnect Ionisation

and lighting electrodes from their wiring.

Unscrew six nuts to release combustion

chamber front panel and pull the assem-

bly towards you. Reassemble in reverse

order.

4. Ionisation electrode

Carry out step 1 and 2 as above.

Disconnect ionisation electrode from its

wiring. Loosen the 2 screws and pull it

out from the combustion chamber front

panel. Replace the ionisation gasket

provided. Reassemble in reverse order.

5. Lighting electrode

Carry out step 1 and 2 as above.

Disconnect lighting electrode from its

wiring. Loosen the 2 screws and pull it

out from the combustion chamber front

panel. Replace the ionisation gasket

provided. Reassemble in reverse order.

6. Burner

Carry out step 1, 2 and 3 as above.

Remove the 4 Philips screw retaining the

burner onto the combustion chamber.

Pull it out with care to avoid any damage

to the ceramic panel protecting the com-

bustion chamber front panel. Replace

the burner gasket. Reassemble in

reverse order.

7. Gas vale assembly

Carry out step 1 and 2 as above.

Unscrew three screws securing the

air/gas connection pipe onto the gas

valve assembly. Disconnect the connec-

tors from gas solenoids and fan. Loosen

the gas pipe nut. Unscrew six nuts to

release combustion chamber front panel

and pull the assembly towards you.

Replace gas filter before fitting the full

assembly back in the boiler.

8. Fan assembly

Carry out all operations mentioned in

step 7. Unscrew the three screws secur-

ing the air/gas connection pipe onto the

gas valve assembly. Separate the gas

valve assembly and the venturi from the

fan assembly by loosen the two hexago-

nal head screws. Reassemble in reverse

order and replace the necessary gas-

kets.

9. Gas section

Carry out all operations mentioned in

step 7. Unscrew the three screws secur-

ing the air/gas connection pipe onto the

gas valve assembly. Separate the gas

valve assembly and the venturi from the

fan assembly by loosen the two hexago-

nal head screws. The venturi and the

gas section can be separated loosing

the 2 screw located at the top of the gas

valve. Replace necessary gaskets

before reassemble in reverse order.

10. Venturi in the gas section

Carry out all operations mentioned in

step 7. Unscrew the three screws secur-

ing the air/gas connection pipe onto the

gas valve assembly. Separate the gas

valve assembly and the venturi from the

fan assembly by loosen the two hexago-

nal head screws. The venturi and the

gas section can be separated loosing

the 2 screw located at the top of the gas

valve. Replace necessary gaskets

before reassemble in reverse order.

11. Drain down

3 drain points are located on the boiler.

1 = DHW circuit drain point

2 = Heating circuit drain point

12. Water filters ( DHW and Heating)

The DHW filter ensures a seal between

the connecting bracket and the pipe to

the DHW flow switch. Drain the boiler as

in step 12. Unscrew the pipe nut and

remove the clip on the hydraulic assy.

Pull the pipe toward you and remove the

water filter from its location.

The C/H filter is located in the right

hydraulic assembly. Remove the return

pipe as described previously and with-

draw the filter. Reassemble in reverse

order.

13. Flow switches

Drain boiler as in step 12. Disconnect

the electrical plug, turn the top cover

anti-clockwise, remove the O-ring and

the brass piston. Reassemble in reverse

order.

14. 3-Way valve

Drain boiler as in step 12. Remove the 3

clips on the 3 way valve. Remove the

clip on the exchanger flow pipe. Pull the

pipe down then pull it out of the 3 way

valve. Disconnect the plug from the

motor. Unscrew the nut on the pipe

between the connecting bracket and the

3 way valve and pull it toward you.

Rotate the 3 way valve body anti-clock-

wise to unclip it from the left hydraulic

assembly.

15. Secondary heat exchanger

Drain both circuits of the boiler as in step

12. Unscrew the 2 fixing screws D and

remove the DHW exchanger from the

front. Prior to reassembly, check that the

4 gaskets are correctly positioned. The

heat exchanger is so designed that it

cannot be remounted incorrectly.

A A

A

A

T

T

1

2

1

2

air separator

D