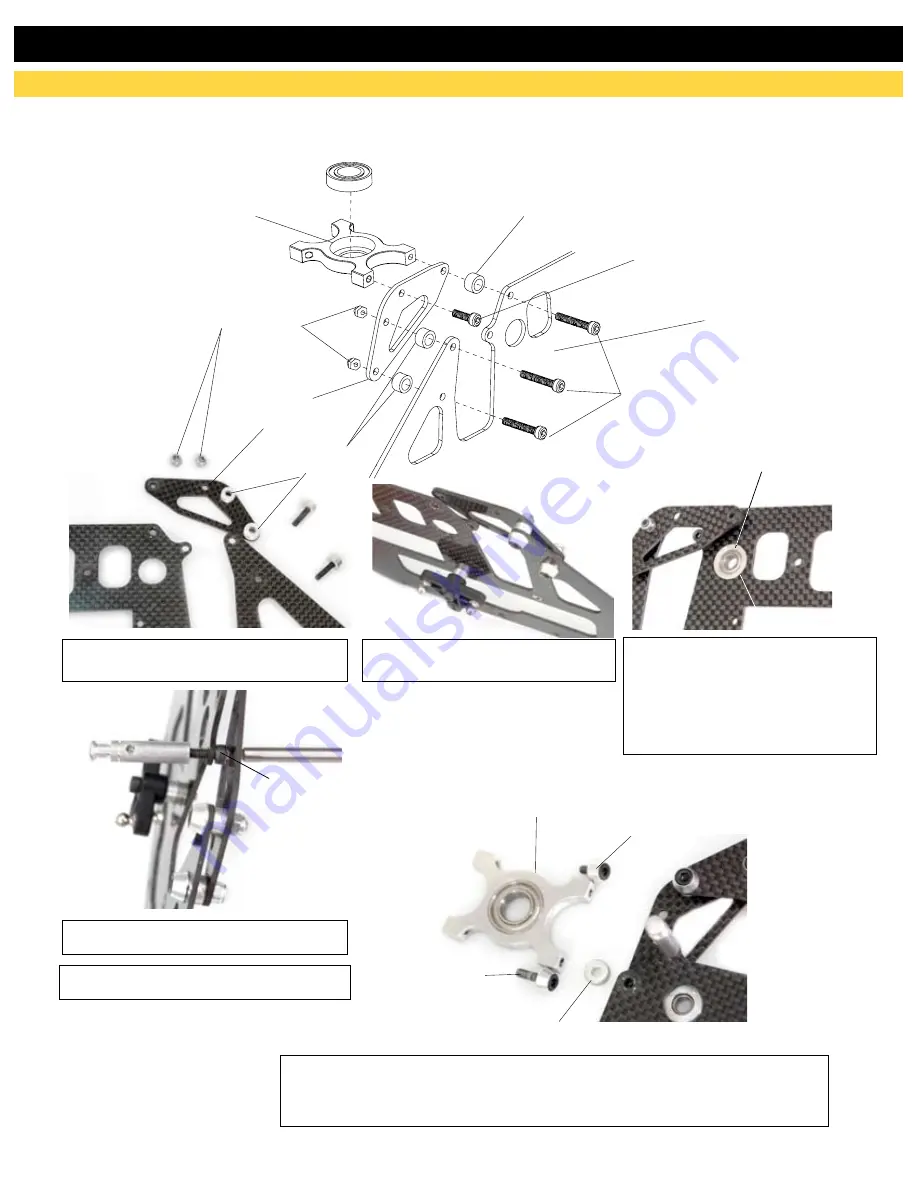

Uppper Bearing Block Assembly

6. Assembly Instructions

CF Main

Shaft Support

(CNE577)

A-Arm

Bearing

(CNE582)

Aluminum

Spacer 3.5mm

(CNE586)

Cap Screws M3x12

(CNM3x12CS)

Aluminum

Spacer 3.5mm

(CNE586)

Upper Bearing

Block, Bearing

(CNBB1019)

Upper Bearing

Block

(CNE593)

Cap Screw M3x8

(CNM3x8CS)

M3 Hex Lock Nut

(CNM3LOCK)

1.

Lay down part; CF Main Shaft Support over

the holes to ensure correct orientation.

2. Be sure to install the plate on the op-

posite side to the bellcrank

3. The hole for the A-arm bearing is

tight and may require sanding in order

for the bearing to fit. Remember to do

this in a well ventilated area and use a

mask.

The bearing should be pushed through

from the inside of the frame.

Flange this side

4. Screw the canopy mount through the main

frames using a M3x8 Cap Screw.

Cap Screw M3x8

(CNM3x8CS)

Upper Bearing

Block

(CNE593)

Aluminum

Spacer 3.5mm

(CNE586)

Cap Screw M3x12

(CNM3x12CS)

Cap Screw M3x8

(CNM3x8CS)

6. Insert the Aluminum spacer between the two carbon pieces. Apply blue lock tight to

the cap screws and insert them through the frame into the bearing block. Make sure the

bearing is facing up.

Do not attach the other side of the frame at this stage.

5. Perform steps 1 to 3 in a mirror fashion to the

other side of the frame.

10

Main Frames

(CNE503)