Page 5

SKU 96382

for technical questions, please call 1-800-444-3353.

operation

filling and adjusting the air spray Gun

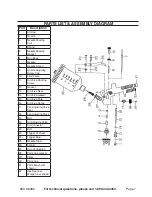

Remove the cover of the Paint Cup (30) and fill with the paint to be sprayed.

Replace and tighten the cup’s cover.

Prepare a spraying test area.

Turn on the air supply and adjust the air regulator on the compressor to no more than

50 PSI.

Point the Spray Gun in the direction of the spray test area and press the Trigger (26).

Adjust the spray pattern (horizontal or vertical) by turning the Air Cap (1).

Adjust the air-to-material mixture by adjusting the Air Adjusting Valve (20).

Adjust the spray width using the Fan Adjustment Valve (18). Do not unscrew com-

pletely.

Adjust the amount of paint flow by using the Fluid Valve (10).

paint preparation

Verify the percentage of paint thinning required for use with a HVLP (High Volume, Low

Pressure) Spray Gun, with the paint or materials supplier. Try thinning a small amount and

testing the spray action. Thoroughly mix material before testing.

spraying techniques

Clean area with a mild detergent and allow to dry prior to beginning.

While spraying, move the Spray Gun in parallel strokes to the object being painted.

Keep 4 to 12 inches between the Spray Gun and the object being painted. This may

be slightly different depending on the flow adjustment and the type of paint being

sprayed.

Release the Trigger (26) at the end of each forward movement; Pull the Trigger again

on the return movement.

When using a vertical pattern, move the Spray Gun in a horizontal motion; With a hori-

zontal pattern, move the Spray Gun in a vertical motion. The round pattern requires a

greater distance from the object being painted.

Maintenance

The Spray Gun must be cleaned

immediately

after use. If the paint drys inside the Spray

Gun, cleaning is much more difficult and the unit may be permanently damaged.

1.

2.

3.

4.

5.

6.

7.

8.

9.

1.

2.

3.

4.

5.