Operation

1. Never force the tool or attachment to

do the work of a larger industrial tool. It is

designed to do the job better and more

safely at the rate for which it was intended.

2. Do not carry the tool by its power

cord.

3. Always unplug the cord by the plug.

Never yank the cord out of the wall.

4. Always turn off the machine before

unplugging.

IF THERE IS ANY QUESTION

ABOUT A CONDITION BEING

SAFE OR UNSAFE, DO NOT

OPERATE THE TOOL!

Grounding Instructions and

Voltage Warning

Common household current is 110-120 volts.

As long as your tool is rated from 110-120V

there will be no complications using this tool

with household receptacles. NEVER try to

plug a 110-120V tool into a 220-240V circuit

(or vice-versa) or serious complications and

possible serious injury to the operator can

occur. The plugs have different shapes to

prevent this.

Check to see if your tool has a two or three-

prong plug. If your tool has a two-prong plug,

you may proceed past the next paragraph. If

your tool has a three-prong plug, please continue

reading the following precautions and instruc-

tions.

If the tool or machine has a three-prong plug, the

third (round) prong is the ground. Plug this cord

only into a three-prong receptacle. Do not

attempt to defeat the protection the ground wire

provides by cutting off the round prong. Cutting

off the ground will result in a safety hazard and

void the warranty.

If a three-prong receptacle is not available, you

may use an adapter, but you must then connect

the green ear on the adapter to the outlet.

Unscrew the center screw of the outlet cover

and put the screw through the green ear. Plug

the adapter’s two prongs into the outlet, and

replace the center screw. Now plug the tool or

machine into the adapter.

DO NOT MODIFY THE PLUG IN ANY

WAY. IF YOU HAVE ANY DOUBT, CALL

A QUALIFIED ELECTRICIAN.

Extension Cords

____________________________________________________________________________

If your tool is double insulated and has a two-prong plug, you may use either a two or three-prong

extension cord. If your tool has a grounded, three-prong plug, you must use a three-prong extension

cord with three-prong receptacles. Only use rounded jacket extension cords listed by the Under-

writers Laboratories (UL). If you are using the tool outdoors, use an extension cord rated for

outdoor use (signified by “WA” on the jacket).

The extension cord must have a minimum wire size depending on the amperage of the tool and the

length of the extension cord. The size is determined by its AWG (American Wire Gauge) rating. The

smaller the gauge, the greater the cable’s capacity. The amount of cords used does not matter. Total

length determines the minimum AWG rating. Every cord must meet the AWG rating. Use the chart

below to determine what AWG rating is required for your situation. Cord length is rated in feet.

Harbor Freight Tools can supply UL listed and outdoor rated extension cords in multiple AWG

ratings if needed.

SKU #33684

Page 3

AMP

Total Extension Cord Length In Feet

Rating

25’

50’

75’

100’

125’

150’

175’

200’

0.0 -10.0

18

18

16

16

14

14

12

12

10.1-13.0

16

16

14

14

14

12

12

12

13.1-15.0

14

14

12

12

12

12

12

--

15.1-18.0

14

12

12

12

12

12

--

--

Содержание 33684

Страница 12: ...SKU 33684 Page 13...

Страница 13: ...SKU 33684 Page 14...

Страница 14: ...SKU 33684 Page 15 Parts Diagram...

Страница 16: ...SKU 33684 Page 16...

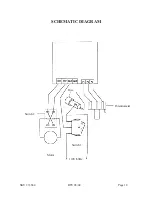

Страница 18: ...SKU 33684 Page 18 Potentiometer Switch2 Motor Switch1 110V 60Hz Fuse SCHEMATIC DIAGRAM REV 08 04...