3. By changing the tool post angle and adjusting the compound rest, you can do internal cutting

(figure 15).

4. After adjusting the angle of the compound rest, you can do bevel cutting (figure 16).

Set-Up Instructions for Threading Gears

By changing the gear set-up it is possible to cut any thread size. The factory set-up for Mini Lathe

gears is as follows (see illustration below):

To change the thread size, use the gear box settings shown on the table on the next page.

B

D

D

A A

C C B

Position A= 20T

Position B= 80T

Position C= 20T

Position D= 80T

SKU #33684

Page 10

Содержание 33684

Страница 12: ...SKU 33684 Page 13...

Страница 13: ...SKU 33684 Page 14...

Страница 14: ...SKU 33684 Page 15 Parts Diagram...

Страница 16: ...SKU 33684 Page 16...

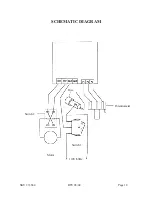

Страница 18: ...SKU 33684 Page 18 Potentiometer Switch2 Motor Switch1 110V 60Hz Fuse SCHEMATIC DIAGRAM REV 08 04...