22

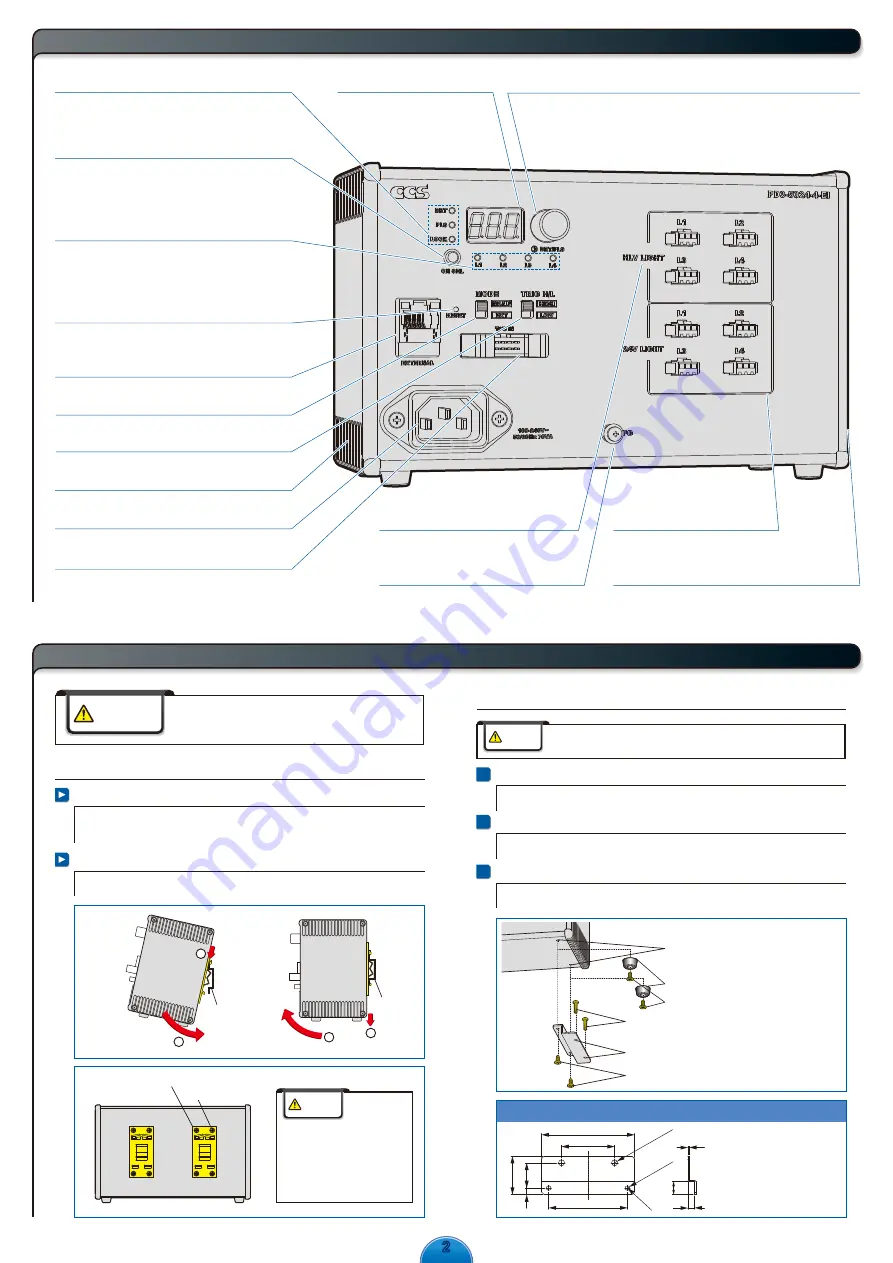

Rear

2

Names and Functions of Parts

Pressed with a pointed object to reset

network settings to their default values.

External Control Reset Switch

Select a Light Unit that is connected to an

output connector from between L1 and L4.

L1 for the 24V Light Units (24V LIGHT) and L1 for

the Spotlights (HLV LIGHT) use the same channel.

Channel Selection Switch

Used for external control with Ethernet communications.

External Control Connector

External Trigger Input Connector

Ground the FG terminal.

FG Terminal

Connect these connectors to the 24V DC Light Units.

(L1 to L4)

Output Connectors

(24V LIGHT)

Fan Air Inlet

(Left side)

This is the air inlet for the cooling fan.

Fan Exhaust Outlet

(Right side)

This is the air outlet for the cooling fan.

Connect these connectors to the Spotlights.

(L to L4)

Output Connectors

(HLV LIGHT)

Setting Indicators

The indicator for the selected channel will light.

When the L1 indicator is lit, the settings for the L1 Light

Unit in the 24V Light Units (24V LIGHT) and the L1 Light

Unit in the Spotlights (HLV LIGHT) can be changed.

Channel Indicators

Press: Switches between the light intensity setting and lighting mode setting.

Press for at least 2 seconds: Locks the settings.

Rotate: Sets the light intensity or lighting mode.

Setting Switch

Displays the setting of the

light intensity or the setting of

the lighting mode.

Digital Display

Selects manual (MANU) or external (EXT) control mode.

Manual/External Mode Selector

Selects the logic of the trigger signal.

Trigger Logic Switch

Connects the power source to the Control Unit.

AC Inlet

BRT lit: The light intensity can be set.

PLS lit: The lighting mode can be set.

LOCK lit: The settings are locked.

Inputs the ON/OFF signal for ON/OFF Mode.

Inputs the trigger signal for Strobe Mode.

3

Installation

Do not place any objects within 20mm from the fan air inlets

or fan exhaust outlets. Insufficient ventilation may cause

heat to accumulate inside the product and result in a fire.

Mounting the Unit to DIN Rail

Mounting to DIN Rail

Hook the tab on the upper part of the Unit on the DIN rail and press the

Unit in the direction indicated by arrow 2 while pressing it in the direction

indicated by arrow 1.

Removing from DIN Rail

Press the Unit down in the direction indicated by arrow 3 and pull it out in

the direction indicated by arrow 4.

DIN Rail

1

2

DIN Rail

3

4

WARNING

Mounting

Removing

1

Removing the Rubber Feet from the Bottom of the Unit

Remove the screws that hold the rubber feet in place using a Phillips

screwdriver.

2

Securing the Brackets to the Base of the Unit

Secure the Brackets to the base of the Unit with the four screws that

come with the Brackets.

3

Securing the Unit with Mounting Screws

Secure the Unit in place with mounting screws. The mounting screws must

be provided by the user.

Securing the Unit with Base Brackets

(Accessories)

* Attach the Bracket to the other side as well.

70

Two, 3.5 dia.

holes

±0.2

±0.2

59.3

29

4-C2

40

Two, 4.5 dia.

holes

19

5

(1)

5

10

Model: BK-PD3

Base Brackets

Rubber foot

Installation screw holes

(Insert the screws to a depth of no more than 5 mm

and use a tightening torque of 0.3 N·m max.)

M3 screws for the rubber feet

Screws for securing the Brackets to the mounting surface

(Prepare the mounting screws yourself according to the installation conditions.)

M3 screws for mounting the Brackets (included with the Brackets)

Holes for the mounting screws (4.5 mm dia.)

Includes two Base Brackets and

four mounting screws

(+ one spare screw)

Do not remove the DIN rail brackets.

If they must be removed and attached

again, make sure that you use the original

screws (or M3 × 4 mm screws).

If other screws are used, they may

short-circuit internal components and

electric shock may occur.

Caution

Always use Base Brackets (model: BK-PD3) when securing the Unit at

its base. If it is secured without the Brackets, the Unit may be damaged.

Caution

DIN rail brackets x 2

Screws x 8

(Unit: mm)