IOM-DA0

5

11. Clean all reusable metal parts according to

owner's procedures.

D. Inspection of Parts:

1. After inspection remove from the work area

and dis card the old “soft goods” parts (i.e.

o-rings, seals, gaskets, etc.) after in spec tion.

These parts MUST be re placed with fac to ry

supplied new parts.

2. Inspect the metal parts that will be reused. The

parts should be free of surface con tam i nants,

burrs, oxides, and scale. Rework and clean

parts as necessary. Surface con di tions that

affect the regulator performance are stated

below; replace parts that can not be re worked

or cleaned.

3. QC

Requirements:

a. Plug

(20);

1. 16 rms finish on its seating surface

for tight shutoff.

2. No major defects on bottom guide

spin dle.

b. Cage

(19);

1. 16 rms finish on cylinder bore. No

“ledges” formed due to wear from

moving dynamic side seal (27) or

wiper seal (16).

c. Lower guide bushing (24) (non-re place-

able):

1. 16 rms finish in bore.

2. Max 0.015 inch (0.38 mm) clearance

be tween plug (20) spindle and lower

guide bushing (24).

4. Staging Material for Reassembly.

a. Inspect and clean parts, as necessary,

from the spare parts kit.

b. Lay out all the regulator parts and check

against the bill of material.

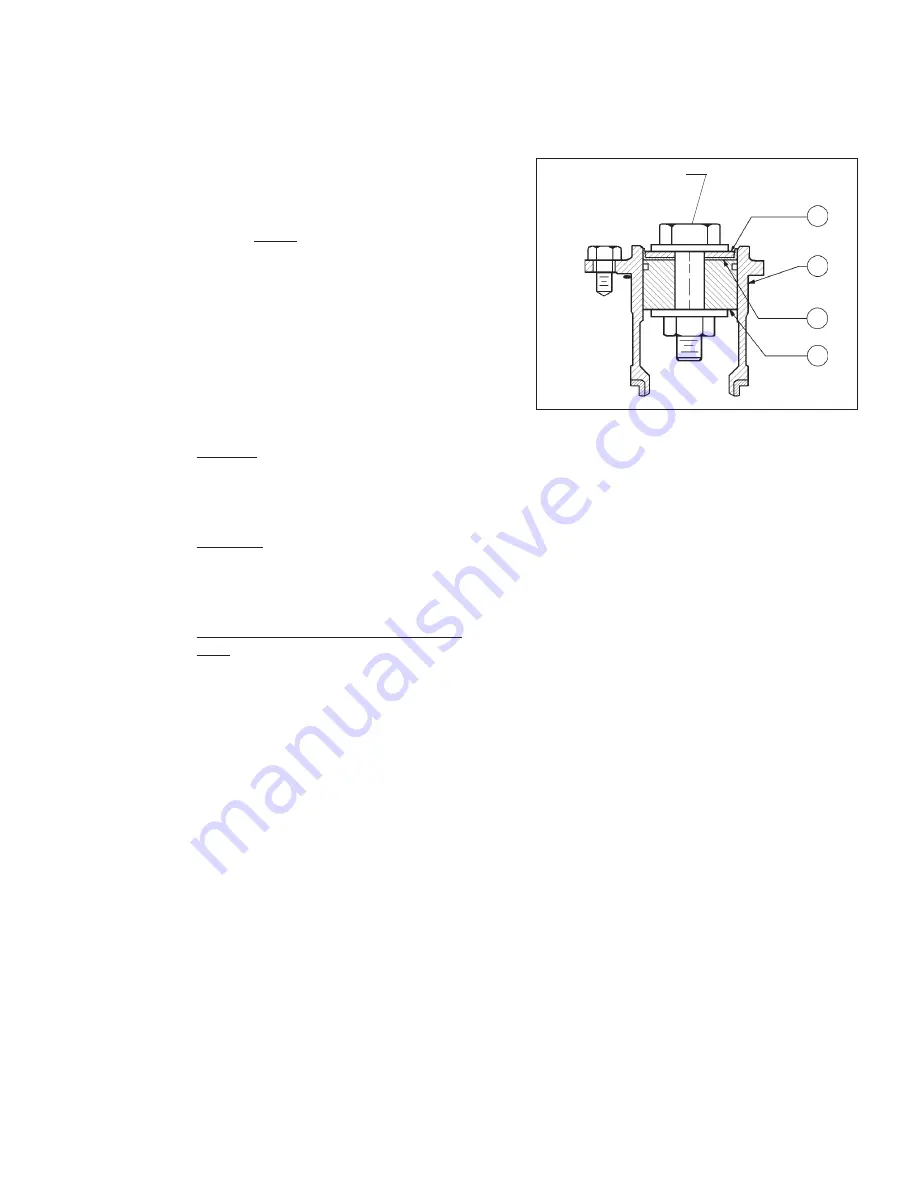

E. Reassembly of the ITA:

1. When replacing the wiper seal (16), the re-

placement wiper seal (16) is “pre-formed”.

It may, however, require re-forming. Under

normal circumstances, this step may not be

required. If needed, reform the wiper seal

(16) by press ing the temporary assembly of

parts into the cage (19) backwards as shown

in Figure 3. The wiper seal (16) is best left in

this position overnight (minimum of two (2)

hours) prior to final re as sem bly.

2. After re-forming the wiper seal, remove parts

(13, 16, 17) from cage (19) and disassemble

this tem po rary assembly.

Figure 3:

Temporary Wiper Seal Assembly

Not supplied. Use any

bolt, two washers and

nut of same approximate

hole size.

17

19

16

13

3. Place wiper washer (17) into “cup” of wiper

seal (16). Holding these parts between thumb

and forefinger, in sert into cage (19) at an ap-

proximate 45° angled approach with wiper

washer (17) on bottom, wiper seal (16) on

top with turned-down lip of wiper seal en ter-

ing cage first. Rotate wiper seal and wiper

washer to a level po si tion approximately half

way down into cage. Allow wiper washer to

rest on bottom of cage.

4. Stretch the corrugated, metal, piston ring

en er giz er of the dynamic seal (27) over the

lower cir cum fer ence of piston-guide bearing

(13). Using thumbs, work the energizer into

the bearing groove.

5. Carefully stretch and slip one of the piston

ring seals over the lower circumference of

pis ton-guide bearing (13), taking care not to

“cut” the piston ring seal. Using thumbs, work

the piston ring seal into the groove of the

bearing. Repeat this procedure with a second

piston ring seal.

NOTE:

A piston ring as sem bly

(PRA) (27), consists of one metal corrugated

energizer and two piston ring seals

6.

Position piston-guide bearing (13) over and

into upper end of cage (19) until the lower

piston ring seal touches the upper lip of the

cage. While gently applying force to press the

piston-guide bearing into the cage, si mul ta ne-

ous ly use fin gers to lightly circumferentially

press the first piston ring seal inwards into

the piston-guide bearing groove until the first