IIl. PRINCIPLE OF OPERATION

1. Movement occurs as pressure variations reg is ter

on the diaphragm (3). The registering pressure is

the inlet (P

1

) or upstream pressure which reg is ters

on the "un der neath" side of the diaphragm (3). The

second pressure registered is the loading (P

LOAD

)

pressure in the spring chamber (2) "above" the

diaphragm (3). The range spring (18) determines

the differential pres sure setpoint (P

SET

). As inlet

I. DESCRIPTION AND SCOPE

The Model 123-1+6+S Differential is designed for high pressure liquid or gas applications to Cashco drawing nos.

32934 (NACE construction) and 32935 (Non-NACE construction). It is used to control differential upstream (inlet or

P

1

) pressure and a loading (P

Load

) pressure to a rotating shaft seal. Sizes are 1/2", 3/4", 1", and 1-1/2" (DN15, 20,

25, and 40).

SECTION III

IOM-123 1+6+S

DIFF

02-16

MODEL 123-1+6+S DIFFERENTIAL

BACK PRESSURE / RELIEF REGULATOR

INSTALLATION, OPERATION & MAIN TE NANCE MANUAL (IOM)

SECTION I

SECTION II

II. INSTALLATION

This unit was designed and is used almost exclusively on compressor and turbo expander seal systems.

REFER

TO COM PRES SOR/EXPANDER MANUFACTURER'S MANUAL FOR DE TAILED INSTALLATION, START-UP

AND SHUTDOWN OF THIS UNIT.

Install regulator with Inlet (P

1

) pressure coming in the side body (1) connection

in accordance with the directional flow arrow cast on body (1).

∆

P

SIZING

= P

1

- P

2

P

1

> P

LOAD

P

1

= P

LOAD

+ P

SET

∆

P

DIFFERENTIAL

= P

1

- P

LOAD

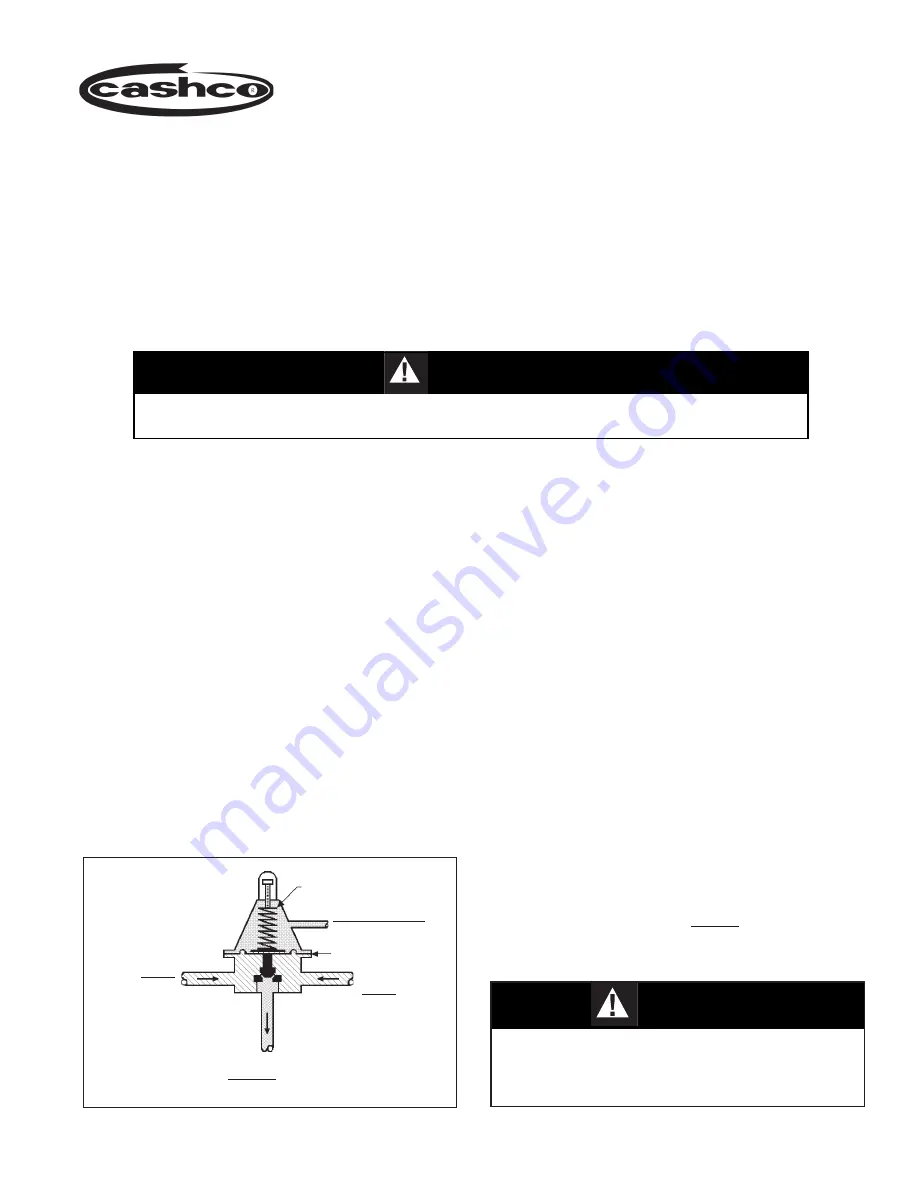

LOADING FLUID

@ P

LOAD

DIA PHRAGM

RANGE SPRING:

SETTING @ P

SET

(Optional)

INLET

@ P

1

OUTLET @ P

2

Model 123-1+6+S Differential Schematic

(P

1

) pressure drops, the range spring (18) pushes

the diaphragm (3) down, clos ing the port; as

inlet (P

1

) pressure increases, the diaphragm (3)

pushes up and the port opens. As the loading

(P

LOAD

) pressure varies, the inlet (P

1

) pressure

tends to follow. An increase in (P

LOAD

) will increase

inlet (P

1

)

pressure by nearly an equal amount ;

a decrease in (P

LOAD

)

will decrease the inlet (P

1

)

pres sure.

2. A complete diaphragm (3) failure will cause the

fluids to mix in the spring chamber (2) or loading

pressure piping. Reg u la tor action will "fail close"

under a di a phragm (3) failure.

3. Under normal operating conditions, the inlet (P

1

)

pressure should be greater than the loading

(P

LOAD

) pressure by the range spring (P

SET

)

setpoint.

INLET

@ P

1

Limit any field hydrostatic test to 1-1/2 times the

Maximum Pressure Rat ing (See Ta ble 1). En sure

that the test pressure is applied uniformly to the

body inlet, body outlet, and spring chamber.

CAUTION

This is not a safety device and must not be sub sti tut ed for a code approved pres sure safety

relief valve or rupture disc. NOT FOR STEAM SERVICE. NOT FOR OXYGEN SERVICE.

CAUTION

ISO Registered Company