F97CMN and G97CMN: Installation, Start-up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

53

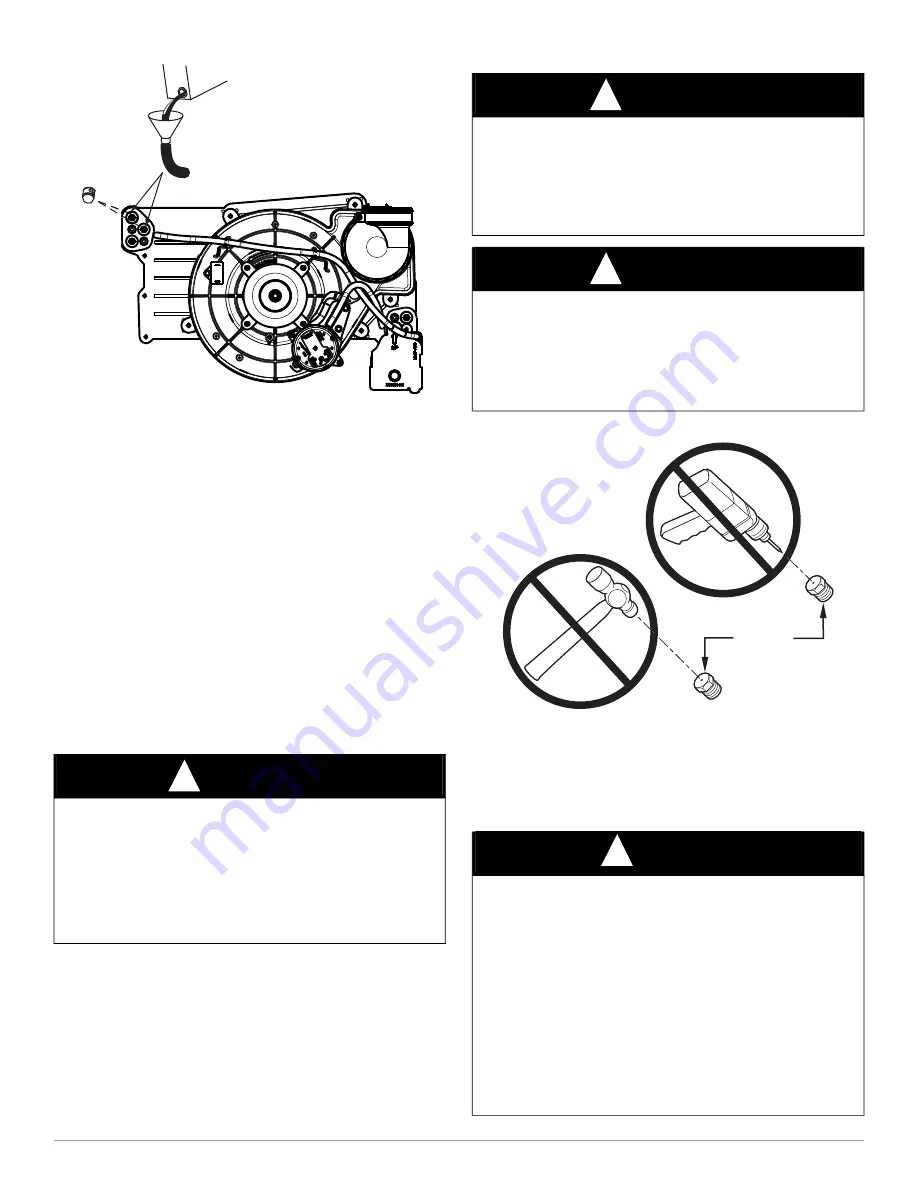

A11392

Fig. 59 – Priming Condensate Trap

(Appearance May Vary)

2. Connect field-supplied 5/8-in. (16 mm) ID tube with attached

funnel to upper collector box drain connection, see

3. Pour one quart (liter) of water into funnel/tube. Water should run

through collector box, overfill condensate trap, and flow into open

field drain.

4. Remove funnel; replace collector box drain plug.

5. Connect field-supplied 5/8-in. (16 mm) ID tube to middle collector

box drain port.

6. Pour one quart (liter) of water into funnel/tube. Water should run

through collector box, overfill condensate trap, and flow into open

field drain.

7. Remove funnel and tube from collector box and replace collector

box drain plug.

Purge Gas Lines

If not previously done, purge the lines after all connections have been

made and check for leaks.

Adjustments

A93059

Fig. 60 – Orifice Hole

For proper operation and long term reliability, the Furnace input rate

must be /-2 percent of input rate on furnace rating plate or as

adjusted for altitude.

The gas input rate on rating plate is for installations at altitudes up to

2000 ft. (609.6M).

WARNING

!

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal injury, death,

and/or property damage.

Never purge a gas line into a combustion chamber. Never test for gas

leaks with an open flame. Use a commercially available soap solution

made specifically for the detection of leaks to check all connections. A

fire or explosion may result causing property damage, personal injury

or loss of life.

CAUTION

!

FURNACE DAMAGE HAZARD

Failure to follow this caution could result in reduced furnace life.

DO NOT push or force gas valve adjusting screw. This can result in

damage to the adjustment screw resulting in incorrect manifold

pressure, which can result in a no heat situation or shorten the life of the

heat exchangers.

CAUTION

!

FURNACE DAMAGE HAZARD

Failure to follow this caution may result in reduced furnace life.

DO NOT redrill orifices. Improper drilling (burrs, out-of-round holes,

etc.) can cause excessive burner noise and misdirection of burner

flames. This can result in flame impingement of heat exchangers,

causing failures, see

Fig. 63

.

NOTICE

!

The NATURAL GAS manifold pressure adjustments in Tables 18 and

19 compensate for BOTH altitude AND gas heating value. DO NOT

apply an additional derate factor to the pressures show in

or

. The values in this table are NOT referenced to sea level; they

are AS-MEASURED AT ALTITUDE.

The heating content of natural gas at altitude may already provide for a

reduction in capacity of the furnace. Be sure to obtain the expected

in-season gas heating value of the gas from the gas supplier BEFORE

making any adjustments for capacity or altitude. Refer to

or

. No adjustments to the furnace may be necessary at altitude

for certain gas heating values.

Refer to the instructions provided in the factory-specified LP/Propane

conversion kit for instructions for setting gas manifold pressures for

LP/Propane applications.

BURNER

ORIFICE