17

MAINTENANCE

Periodic maintenance is necessary to keep all components

functioning as designed. A maintenance log is recommended

to ensure a proper maintenance schedule is followed.

Pumpout Compressor Oil Charge —

Use oil con-

forming to Carrier specifications for centrifugal or screw com-

pressor use. Oil requirements are listed in Table 6.

Monitor and adjust compressor oil level as often as

necessary. When replacing lost oil, add the same type of oil that

is used in the chiller being pumped out.

Table 6 — Pumpout Compressor Requirements

The pumpout oil separator comes pre-charged with 13 oz of

ISO viscosity 220 POE (Polyol Ester) oil. The pumpout com-

pressor is approved for use with ISO viscosity 220 POE oil or

ISO viscosity 68 POE oil. The pumpout compressor is also fac-

tory precharged with POE oil.

Oil should be visible in the pumpout compressor sight glass

both during operation and at shutdown. Always check the oil

level before operating the pumpout compressor.

Oil can be added to the 1/4-in. SAE flare access valve port

running from the top of the oil separator to the compressor

while the compressor is running. Be careful not to overfill.

NOTE: Compressor access valve has a self-sealing fitting

which will require a hose connection with a depressor to open.

To change or remove oil, the compressor will have to be re-

moved from the assembly. Compressor can be disconnected

from connected tubing by the quick connect fittings at suction

and discharge and oil recovery line.

Prior to removal, close service valves 2, 3, 4, and 5, and run

the pumpout compressor in AUTOMATIC until the vacuum

switch is satisfied and the compressor shuts off.

Move pumpout selector switch to OFF, and turn off all power

to unit prior to removing compressor unit from pumpout as-

sembly frame and connecting tubing.

Service valves 2, 3, 4, and 5 remain closed while compres-

sor is removed. Put compressor back in place. Use the torque

values listed in Table 7 for reassembly:

Table 7 — Torque Values for Reassembly

Be sure to use backup wrench and pull a deep vacuum in the

serviced pumpout tubing prior to any refrigerant exposure. At

this point, confirm that the oil level is satisfactory and put the

pumpout back in service.

Storage Tank —

To prevent moisture and contaminants

from entering the storage tank, maintain positive pressure in

the tank when not transferring refrigerant. Leak test the storage

tank periodically.

Ordering Replacement Parts —

The following in-

formation must accompany an order for Carrier-specified parts:

• machine model number and serial number

• name, quantity, and part number of the part required

• delivery address and method of shipment

TROUBLESHOOTING

Information on troubleshooting for the PPS system is in-

cluded in Table

8.

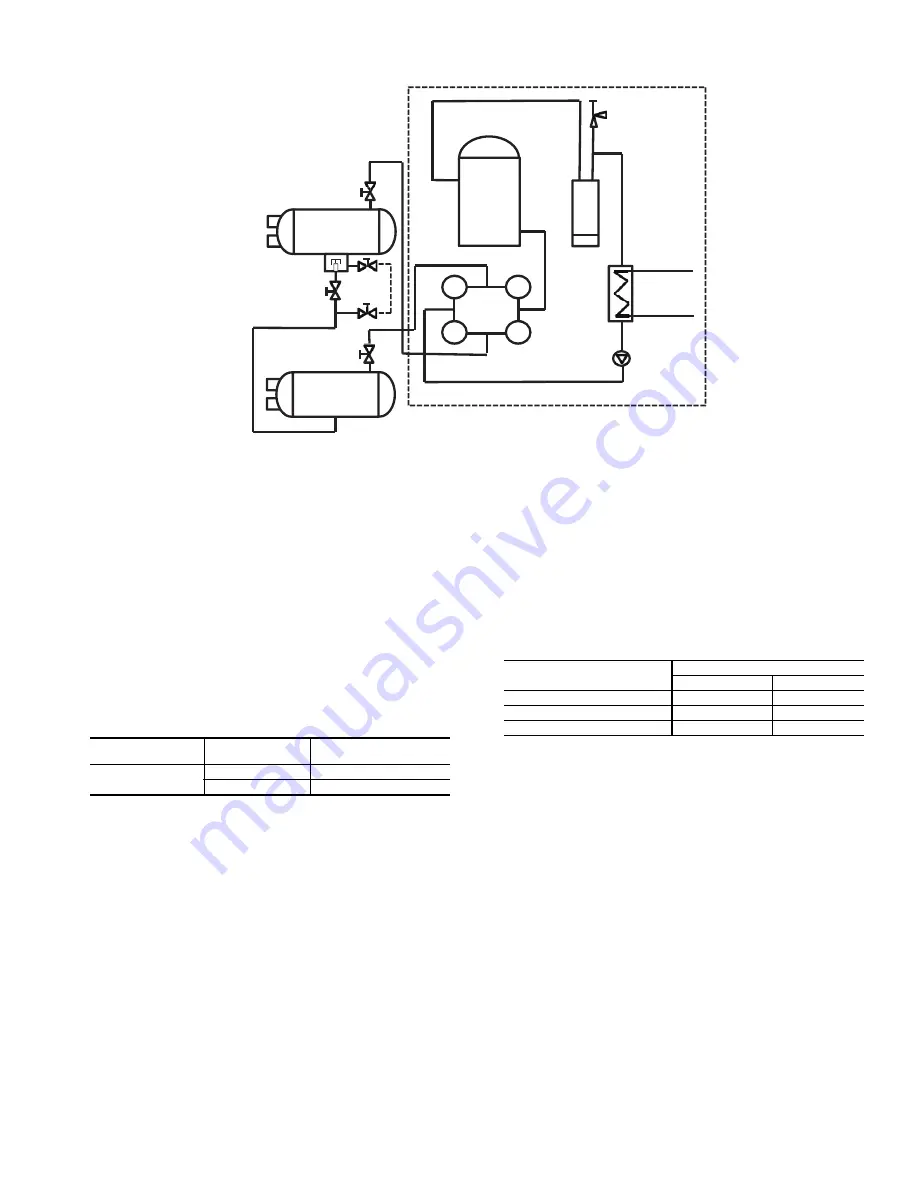

a19-2435

7

1a

11

8

1b

5

3

4

2

PUMPOUT

COMPRESSOR

OIL

SEPARATOR

RELIEF

VALVE

PUMPOUT

CONDENSER

CHECK

VALVE

CONDENSER

COOLER

Fig. 11 — Typical Optional Pumpout System Piping Schematic without Storage Tank

NOTE: Valve 8 is only applicable for products with linear float valves.

REFRIGERANT

ISO

VISCOSITY

CARRIER

SPECIFICATION NO.

R-134a

68

PP47-31

220

PP47-32

PARAMETER

VALUES

ft-lb

Nm

Suction

80 to 100

109 to 136

Discharge

50 to 60

68 to 81

O-ring Face Seal

7 to 9

10 to 12

Содержание 19XR Series

Страница 19: ......