Model 99FRD, 100CRD & 102CRD oil burners — Instruction manual

Carlin part number MN99102 Rev. 08/20/08

– 12 –

3. Prepare burner

(continued)

• The nozzle line heater needs power when the burner is in standby (no

call for heat from the appliance). Make sure the nozzle line heater is

powered directly from the 120 VAC HOT line, not through the appliance

operating control circuit. The nozzle line heater wiring should be shown

on the wiring diagram supplied with the appliance/burner unit.

• The nozzle line heater is supplied with an electrical disconnect harness,

allowing removal of the combustion head assembly without discon-

necting wires. Position the heater harness disconnect in the rear of

the blower housing, above the blower access cover. The wire leads to

the disconnect route through the side of the housing into the junction

box.

When first starting the burner, or after the service switch has

been off for some time, the heater requires about 15 minutes

to bring the oil to operating temperature.

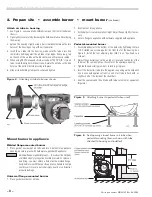

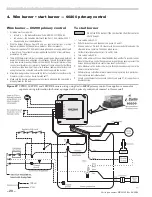

Figure 14

One-line fuel system

One-line fuel system requirements

See Figure 14. The standard burner fuel unit is a single-stage, 3450-RPM

oil pump. Apply this fuel unit only on one-line systems where the fuel sup-

ply is on the same level with, or higher than, the burner. This ensures oil

flow by gravity. Also make sure the total lift does not exceed 8 feet (height

difference from bottom of oil tank to fuel unit). For other conditions, you

must provide a two-line fuel system. You may also have to change the fuel

unit to a two-stage type.

Inspect/install fuel supply

Inspect the oil supply system. Ensure that the fuel lines are

correctly sized and installed and that the fuel flow is unob-

structed, the oil tank is clean and only # 1 or # 2 heating oil

are supplied. Failure to supply a reliable oil flow could result

in loss of heat and potential severe equipment damage.

Nozzle line heater

• Oil burners often operate in spaces where temperatures tend to be

cool, typically 60°F or lower. Cool oil has higher viscosity, which can

affect atomization, ignition, combustion and fuel consumption. The

nozzle line heater avoids this problem by heating the nozzle line oil to

between 120°F and 130°F, resulting in smoother ignition and improved

combustion.

General guidelines:

• When installing oil lines, use continuous runs of heavy-wall copper

tubing if possible.

• Check fuel unit (oil pump) data sheet for recommended line sizing, lift

limitations and maximum length.

• Check all connections and joints to ensure they are air-tight.

• Use flare fittings. Do NOT use compression fittings.

• Never use pipe sealing tape. Fragments can break off and plug fuel line

components.

• Install a shut-off valve at the tank and one near the burner. (Use fusible

handle design valves when possible or when required by codes.)

• Install a large capacity fuel filter (rated for 50 microns or less) near the

burner.

Fuel unit bypass plug

The fuel unit is shipped with its bypass plug not installed,

intended for a one-line oil system. Install the bypass plug only

if connecting to a two-line oil system. Operating with the plug

in place on a one-line system will damage the fuel unit and

could lead to oil leakage and fire hazard.

If the fuel line or fuel supply is above burner, never exceed 3

PSIG pressure at the fuel unit inlet. Install a suitable OSV to

reduce the pressure. Operating the fuel unit with higher inlet

pressure could result in fuel unit seal damage, oil leakage

and potential fire hazard.

Содержание 100CRD

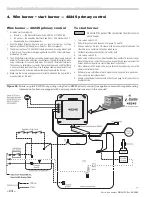

Страница 15: ...Model 99FRD 100CRD 102CRD oil burners Instruction manual Carlin part number MN99102 Rev 08 20 08 15...

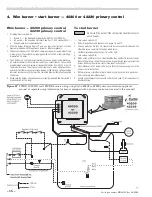

Страница 17: ...Model 99FRD 100CRD 102CRD oil burners Instruction manual Carlin part number MN99102 Rev 08 20 08 17...

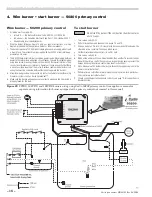

Страница 19: ...Model 99FRD 100CRD 102CRD oil burners Instruction manual Carlin part number MN99102 Rev 08 20 08 19...

Страница 21: ...Model 99FRD 100CRD 102CRD oil burners Instruction manual Carlin part number MN99102 Rev 08 20 08 21...