9

5

.

Drill a 3/16” hole in line with the throttle arm on

your engine.

4

.

Reinstall the engine and bolt in place using

the 6-32 bolts and aircraft lock nuts.

3

.

Place your engine on the mounts and mark

the location of the engine mounting holes on

the mounts. Remove the engine and drill a

5/64” hole at the marks.

Wing Assembly

1

.

The wing is one piece so all there is to do is

glue the aileron and flap hinges in place. Use

the straight pins in the holes in the hinges to

make sure they stay centered. Make sure

aileron is aligned with wing tip and flap does

not rub against aileron and both work freely.

2

.

Remove the pins and glue in the same man-

ner as we did the elevators and rudder.

Deflect the aileron and flap fully in one direc-

tions and apply one drop of thin CA. Turn the

wing over and deflect the aileron and flap in

the other direction and apply one drop to glue.

Repeat process of two drops of glue on each

hinge. Repeat for the other side of the wing.

3

.

Install the two servos in the cutout provided

with the output arm to the rear. You will need

a 12” extension on the out board servo. Use

the string provided to pull the servo lead to the

hole in the center of the wing. As the lead

passes the inboard servo attach the wire from

the servo and pull both to the middle.

4

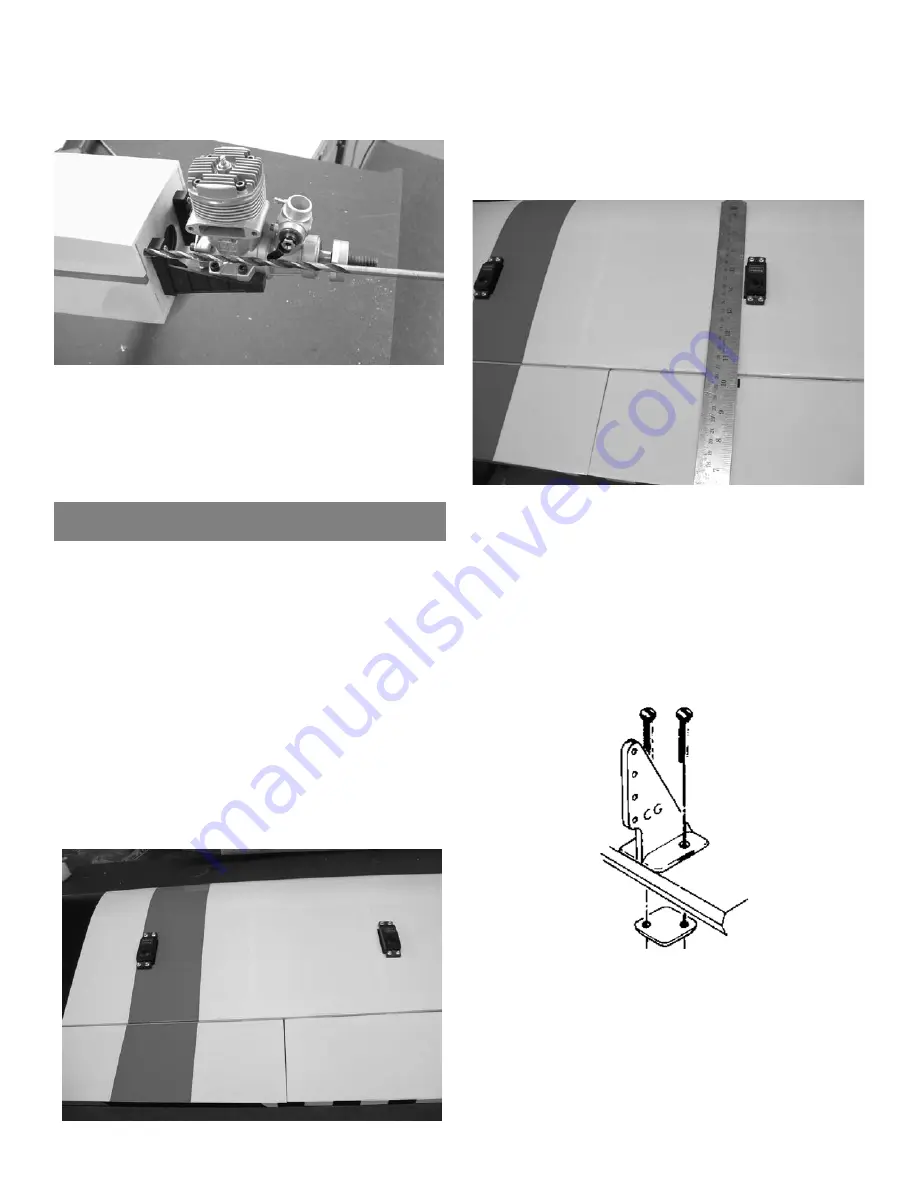

.

Lay a straight edge along side the servo and

mark the location of the horn on the aileron

and flap. Mark both aileron servos on the out-

board side of the servo (toward the tip of the

wing). If you plan to use the flaps as just flaps

you will have to mount the horn on the same

side of the servo on both sides(right flap on

the inboard side left flap on the outboard side)

If you plan to use them just as ailerons and

have them coupled to the ailerons you should

mount the horns as you did for the ailerons.

5

.

Mount the control horns using the #2 screws

with the nylon plate on top. Make sure the

holes for the clevis to connect to are aligned

over the hinge line.