16

❏

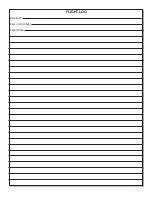

3. Connect your servo leads and the battery switch lead to

the receiver. Connect a Y-harness to your aileron channel. Wrap

the receiver in latex foam rubber and install it in the fuselage.

❏

4. Route the receiver’s antenna lead through the antenna

tube as shown. Make sure that your antenna is fully extended.

FUEL TANK & BATTERY

INSTALLATION

FUEL TANK ASSEMBLY

❏

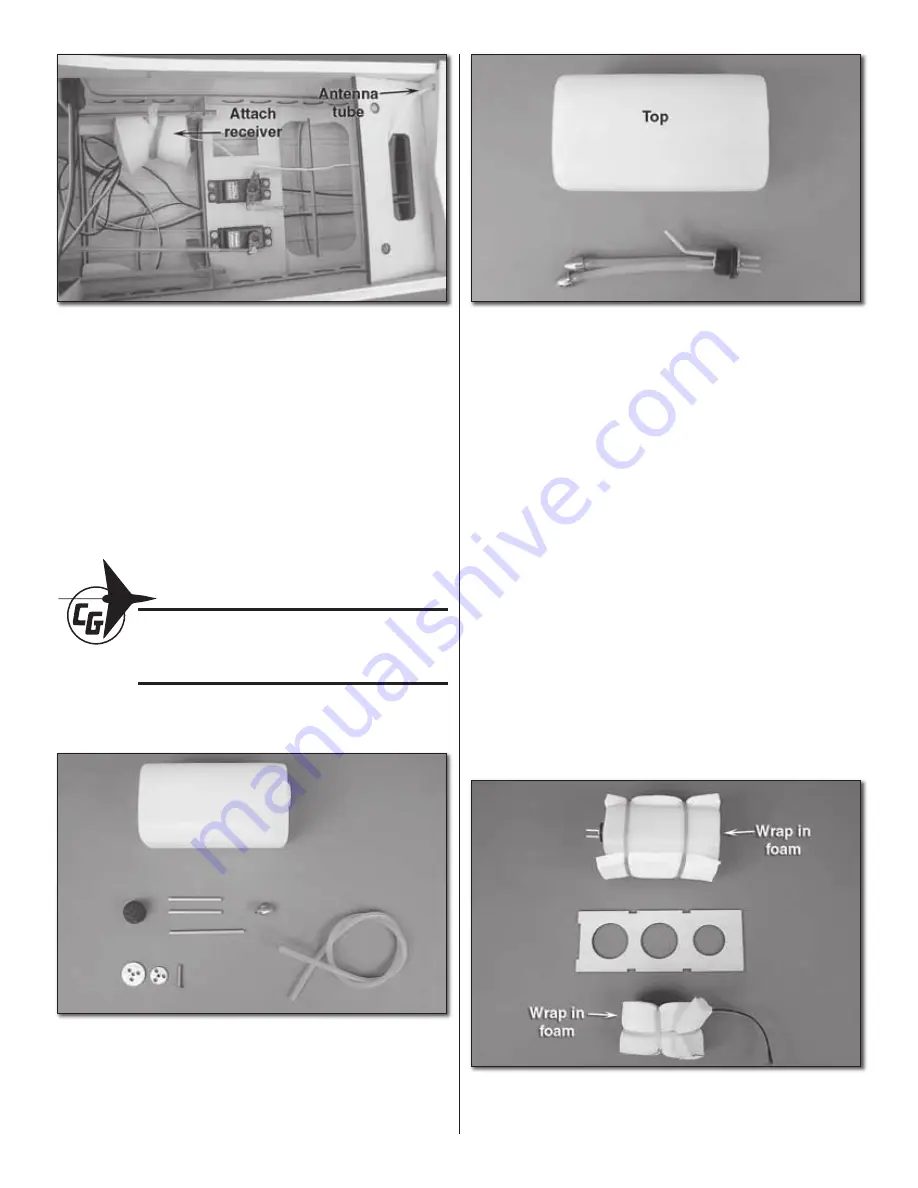

1. Gather the parts required for the fuel tank. You will

need: one (1) plastic fuel tank, one (1) rubber stopper, one

(1) stopper washer, one (1) stopper nut, one (1) stopper

screw, three (3) aluminum fuel lines, and one clunk. If you

are going to use a three line tank, you will need to purchase

a third fuel clunk and some extra fuel tubing.

❏

2. Assemble the stopper as shown with the vent line

pointing up to the top of the tank. The top of the tank must be

one of the wide sides so that the tank lays down as fl at to the

tray as possible. Make sure that the clunk is spaced at least

1/4" [6mm] from the back of the fuel tank – this will prevent it

from hanging up when the airplane fl ies inverted.

Note:

We

elected to use the three line setup, so there are two clunks

(only one is supplied with this kit).

❏

3. Label your vent, fi ll, and carb lines coming out of the

tank and install the stopper onto the tank. Do not overtighten

the stopper: this can cause the tank to split. Draw an arrow

on the back of the tank so you can easily tell which side is

up (vent).

MOUNT THE FUEL TANK & BATTERY

You may want to wait until your model is ready to balance to

perform this section. The 1.20 two-stroke that we installed in

this manual required a few ounces of ballast weight to arrive

at the proper C.G. with the battery installed on the fuel tank

tray as shown in the next steps. Installing a 1.20 four-stroke

without using lead ballast required the battery to be moved

to the bay just behind the fuel tank.

❏

1. Wrap your fuel tank and radio battery in latex foam

rubber. Use a minimum of 1/4" [6mm] thick foam. Locate the

fuel tank tray.