10

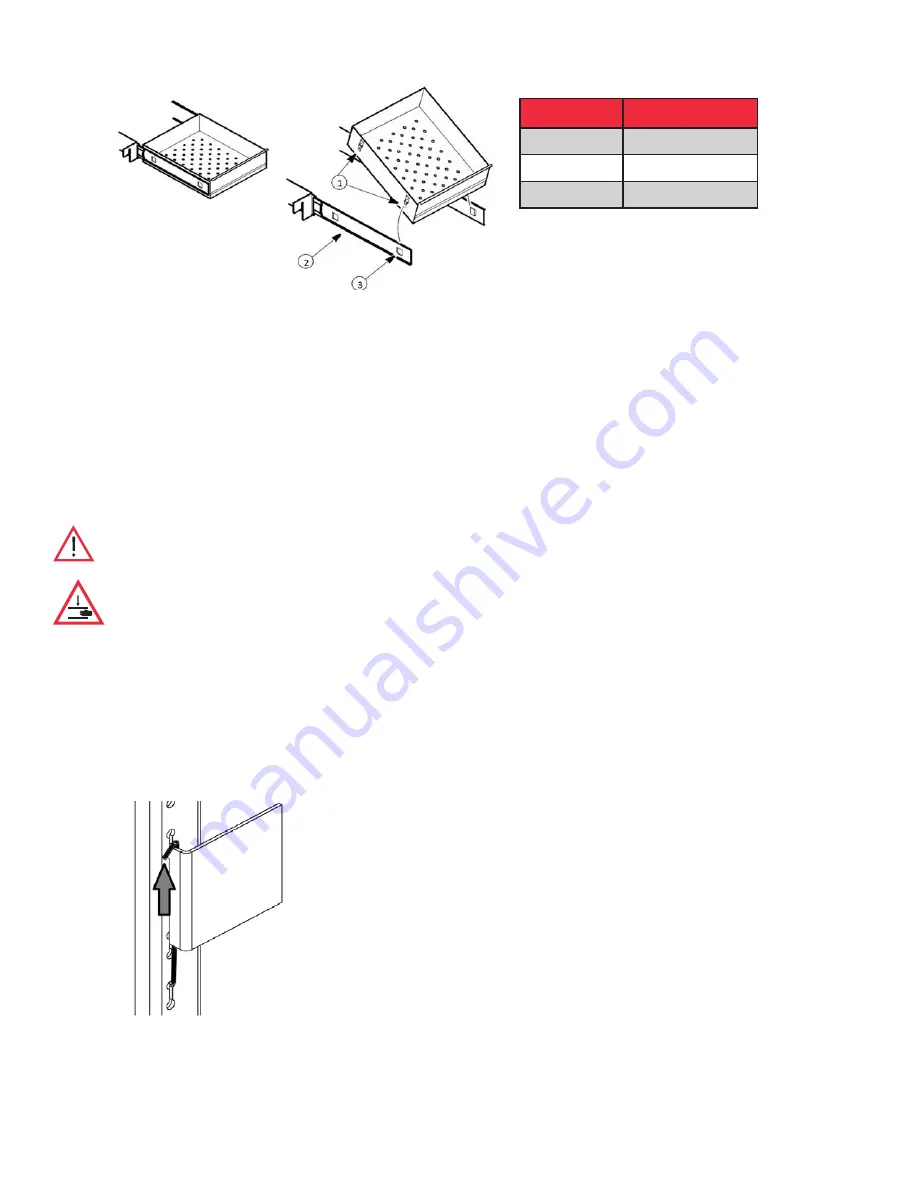

7.4.2 Reinstalling the Drawers

To reinstall the drawers, complete the following steps

(refer to

Figure 2

):

1. Pull both the slides of the drawer towards you until the slides are fully extended.

2. Position the drawer between the slides and with the back facing end raised at 45 degree angle, insert the mounting

clips at the front into the slots on front of the slides.

3. Push the back of the drawer down between the slides and insert the basket tabs into the slots at the back.

Note

The drawers fit snugly between the slides. Push on the back of the drawer from the inside to insert the

drawer tabs completely into the slots. Make sure both the drawer tabs are aligned with the slots on the

slides before pushing the drawer down between the slides.

CAUTION:

Be careful when reinstalling the drawers to avoid possible pinching.

7.4.3 Changing Drawer Position

Drawer slides have a small wire safety clip at the front pilaster which prevent the slides from falling when the drawer is

removed. To change the position of the drawer slides, complete the following steps:

1. Locate the safety clip.

2. Slip a small screwdriver under the bottom of the wire clip and pry the clip towards the inside of the freezer.

Figure 3. Clip Removal

Figure 2. Drawer Removal and Installation

Label

Description

1

Tabs

2

Drawer slide

3

Slot

3. Raise the back of the drawer almost to a vertical position and disengage the front mounting clips from the sides.

Содержание CAX1230FA

Страница 35: ... This page intentionally left blank ...