HRF

MF05

7

R

EPAIRS

& R

EPLACEMENTS

5.1

Safety Warning – Disconnection from Supply

Always ensure that the furnace is disconnected from the supply before repair work

is carried out.

5.2

Safety Note - Refractory Fibrous Insulation

This furnace contains refractory fibres in its thermal insulation. These materials may

be in the form of fibre blanket or felt, vacuum formed board or shapes, mineral wool

slab or loose fill fibre.

Normal use of the furnace does not result in any significant level of airborne dust from these

materials, but much higher levels may be encountered during maintenance or repair.

Whilst there is no evidence of any long term health hazards, we strongly recommend that safety

precautions are taken whenever the materials are handled.

Exposure to dust from fibre which has been used at high temperatures may cause

respiratory disease.

When handling fibre always use an approved mask, eye protection, gloves and long

sleeved clothing.

Avoid breaking up waste material. Dispose of waste fibre in sealed containers.

After handling rinse exposed skin with water before washing gently with soap (not

detergent). Wash work clothing separately.

Before commencing any major repairs we recommend reference to the European Ceramic Fibre

Industry Association Bulletin No. 11 and the UK Health and Safety Executive Guidance Note

EH46.

We can provide further information on request. Alternatively our service division can quote for

any repairs to be carried out at your premises or ours.

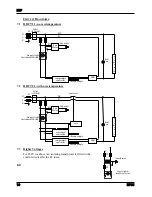

5.3 Temperature Controller Replacement

201. This controller is fitted to the back of the control panel; in many models this can be separated

from the base by removal of two screws.

Before handling the controller:

wear an anti-static wrist strap

or otherwise avoid any possibility

of damage to the unit by static electricity.

Refer to the detailed instructions supplied with the replacement controller.

2132, 2416, 2408 etc. Ease apart the two lugs at the side; grip the instrument and withdraw it from

its sleeve; push in the replacement.

5.4 Solid-state Relay Replacement

Disconnect the furnace from the supply and remove the furnace back panel.

Make a note how the wires are connected to the solid state relay, and disconnect them. Remove

the solid state relay from the base panel or aluminium plate.

Replace and reconnect the solid state relay ensuring that the heat-conducting thermal pad is

sandwiched between the relay and the base panel or aluminium plate. Alternatively a thin layer of

white, heat-conducting silicon paste may be applied between the new relay and the plate.

Replace the removed panel.