Step 11

Level and Square

58

docs.carbide3d.com

59

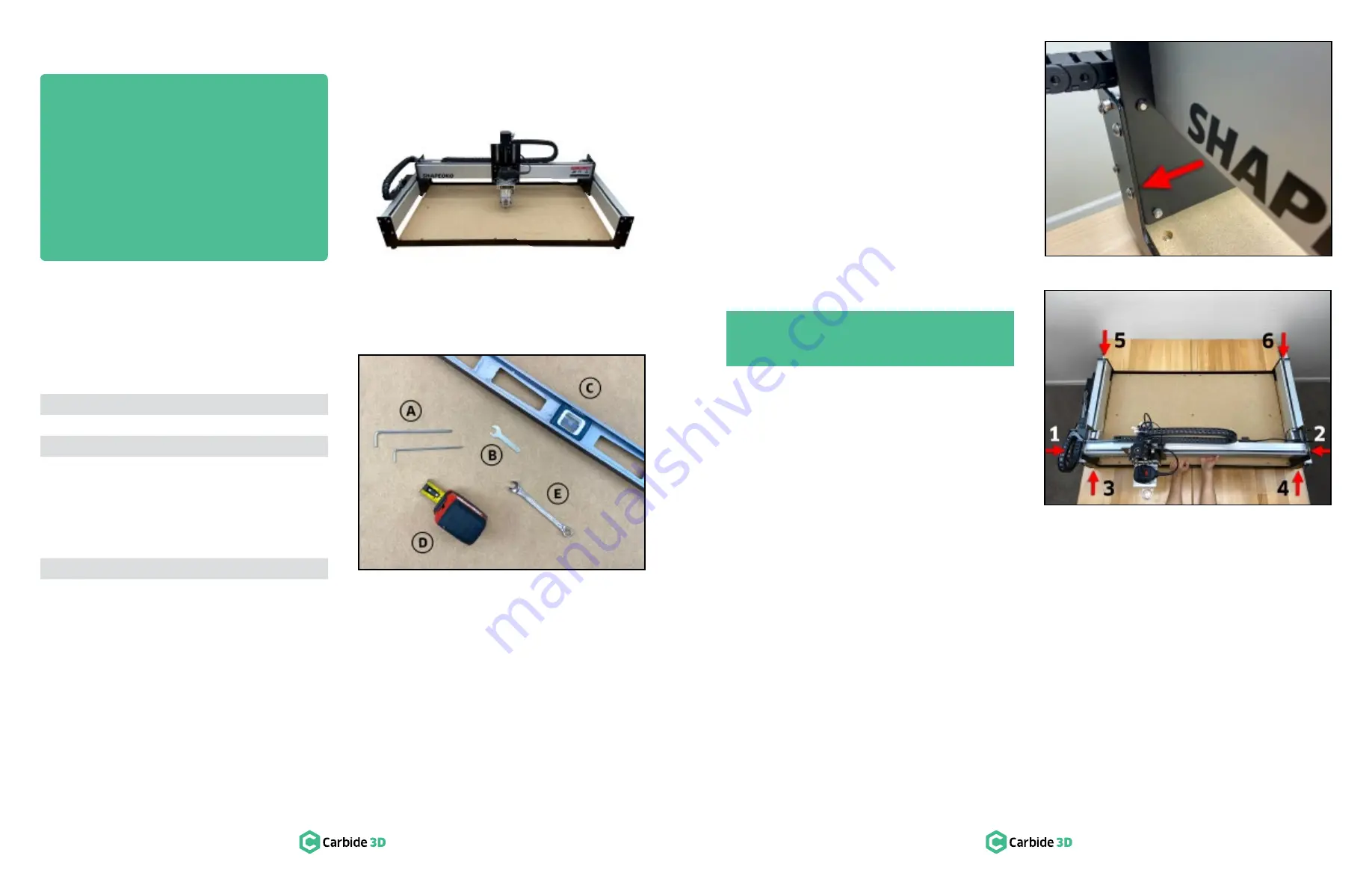

Required Tools

See

Figure 11‑2

:

Item Description

Qty

A

3 and 4mm Hex Key

1

B

10mm Wrench

1

C

Level (not included)

1

Recommended Tools

See

Figure 11‑2

:

Item Description

Qty

D

Tape Measure

1

E

10mm Combination Wrench

1

Confirm Level

The baseframe received a preliminary leveling in step 2.

1.

Double-check for level now at several different points across the machine: front-to-back, side-to-side,

and diagonally. Adjust the four (4) leveling feet where necessary.

Confirm Tension of the V‑Wheels

The V-wheels were tensioned in step 4.

1.

Double-check each one now and adjust where necessary. Refer back to

Figure 3‑4

and

3‑5

(page 18)

for a detailed explanation of eccentric nuts and instructions on tensioning V-wheels.

Square the Machine

The machine is gradually brought into square by

first loosening all structural support screws, then

tightening again while

SIMULTANEOUSLY

holding

the X-rail parallel to the front and rear endplates.

1. Use the 4mm hex key to loosen all twenty-four

(24) M6x12mm button head cap screws 1

/

2

turn

back from snug (there are four (4) in the ends of

each aluminum extrusion rail).

2. If necessary, use the 3mm hex key to loosen

the fifteen (15) M5x25mm button head screws

securing the baseplate to baseframe (these

screws were not tightened in step 2).

3.

With all thirty-nine (39) structural screws now

loose,

HOLD

the X-rail

FORWARD

, bringing

both Y-carriage plates squarely into contact

with the front endplate. See

Figure 11‑3

.

4. Maintain

FORWARD PRESSURE

and use the

4mm hex key to fully tighten the sixteen (16)

M6x12mm button head cap screw sets 1-4, in

numbered order, shown in

Figure 11‑4

.

5.

Move the X-rail to the rear and maintain

REARWARD PRESSURE

and use the 4mm hex key to fully tighten the eight (8) M6x12mm button head

cap screw sets 5-6, in numbered order, shown in

Figure 11‑4

.

6.

Use the 3mm hex key to fully tighten the fifteen (15) M5x25mm button head cap screws of the MDF

baseplate.

Congratulations! Assembly is now complete!

Next Steps

On the following pages you will find helpful information to get you ready to use your Shapeoko XL.

1. Connect to Power

2.

Download the Software

3.

Configure

Carbide Motion 5

4. Run the Test Project

5. Workholding

6. Cutting Tutorials & Projects

7. User Guides & Video Tutorials

PRO TIP:

During this step of the assembly, it

may be helpful to have another set of hands.

Figure 11-2

Figure 11-3

Figure 11-4

Содержание Shapeoko XL

Страница 1: ......