18

LPG GAS ONLY

Do not install this appliance in a room below ground level. This does

not preclude installation in rooms which are basements with re-

spect to one side of the building but open to ground level on the

opposite side.

Failure to install appliances correctly is dange-

rous and could lead to prosecution.

WARNING: It is the responsibility of the installer to ensure

that the standards referred to below are strictly adhered to.

The manufacturer declines all responsibility deriving from the

failure to apply these standards.

CONNECTION TO THE GAS MAINS

IMPORTANT: The installation must be carried out in compliance

with local regulations. Install the appliance in a well-ventilated

room, check that the gas meter capacity and pipe diameters are

sufficient to supply all the connected appliance. Do not forget to

install, upstream of the appliance, a gas cock no smaller than 1/2”,

in a clearly visible and accessible position.

Before connecting the appliance, check the data plate affixed

to the inner side of the Plate Warming Door or to the back of

the appliance for the type of gas, the working pressure and

the capacity.

NOTE:

- do not forget to fit the seal

- the soft or flexible hose must be visible along its entire length,

and must pass behind the appliance at floor level where the

supply comes from the opposite side.

- Important: once installation is complete, check that all connec-

tion seals are tight using a soapy solution, never a flame.

- check that the gas pressure entering the cooker is as required:

Liquid gas: butane

G28/30mbar

propane

G31/37mbar

Methane gas: natural

G20/20mbar

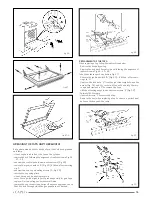

ADAPTATION FOR DIFFERENT TYPES OF GAS

To adapt the cooker for a different type of gas than that for whi-

ch it was designed (see the labels on the inside of the Plate War-

ming Door), carry out the following operations:

a) disconnect the appliance from the mains to avoid any acci-

dental contact.

b) replace the burner injectors on the hob:

c) adjusting the minimum settings of the hob burners

No adjustment of the burner primary air is required.

Once the gas regulation is completed, replace the data plate insi-

de the plate warming door (Fig. 3) with the correct one supplied

with the injector set.

CHANGING THE INJECTORS FOR

THE DIFFERENT TYPES OF GAS

Hob Burners:

- remove the pan stands, the flame dividers and the burner heads

from their mountings;

- select from the pack of injectors, checking the corresponding

indication on the injector, the appropriate one for each burner

and for the desired type of gas (see “table of technical charac-

teristics”, page 3);

- using a 7 mm spanner unscrew the injectors fitted (Fig. 39)

Replace them with the appropriate injectors and tighten them

without excessive force;

- replace the heads and the caps of the burners on the burner cap

supports;

- adjust the low settings as indicated in the chapter “Adjusting

the low settings” below.

ADJUSTING THE LOW SETTINGS (REDUCED FLOW)

Adjusting the low settings of the hob burners (Fig. 40)

- light one burner at a time, in the fully on position, remove the

knob using a screwdriver, unscrew by approximately three turns

minimum screw H located on the right hand side of the stem,

turn the tap to the left to the reduced gas flow position and

turn screw H until a small regular flame is obtained.

With butane or propane gas the screw will be screwed fully down.

These screws are pierced and mounted on the tap according to

the type of burner.

N.B.

Check that when turning the tap rapidly from the fully on position

to the minimum position, the burner does not go out.

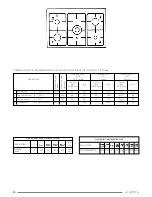

The taps are colour-marked (see table below):

Rapid burner

R

diameter

0.42 mm

yellow

Semi-rapid burner

B

diameter

0.32 mm

blue

Auxiliary burner

A

diameter

0.27 mm

red

Fish burner

P

diameter

0.57 mm

white

Kwali burner

BK

diameter

0.57 mm

white

ELECTRICAL CONNECTION

(varies according to model)

This appliance must be installed by a qualified electrician to com-

ply with the relevant Institute of Electrical Engeneers (I.E.E.) re-

gulations and also the local electricity supply company require-

ments.

Check that the network characteristics (voltage, nominal power,

etc.) correspond to those indicated on the small plate mounted

on the inside of the oven or Plate Warming Door or on the back of

the cooker.

The appliance is designed for installation with connection to a sin-

gle phase earthed supply, 230V~50Hz.

For combination cookers (gas-electricity), see the following note.

For direct connection to the network (cable without plug) an dou-

ble pole swich should be fitted upstream of the appliance with a

contact opening distance of at least 3mm.

The appliance should be earthed using particular care by a quali-

fig. 39

fig. 40

Содержание CR1001SS

Страница 2: ......

Страница 24: ...2 12VFQ011640 GB spazio per targa dati ...