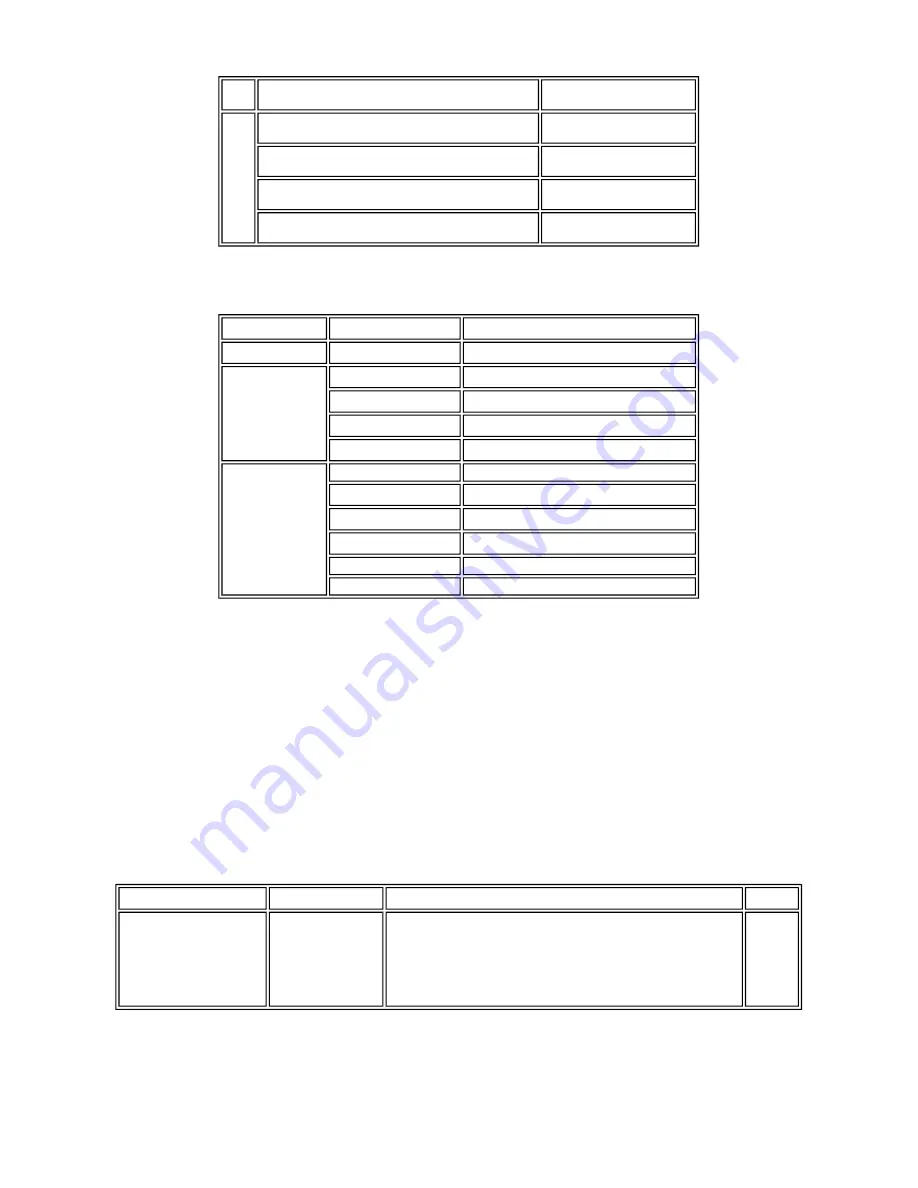

(3) Ink tank (target value)

Black

1,500 character pattern

6,000 pages

Color A4, 7.5% duty per color pattern

3,500 pages

A4, photo, borderless printing

400 pages

4 x 6, photo, borderless printing

3,000 pages

Postcard, photo, borderless printing

1,100 pages

Pattern

Ink tank used

Print yield

Black text

PGI-5BK

Approx. 870 pages

Color chart

PGI-5BK

Approx. 1,400 pages

CLI-8Y

Approx. 510 pages

CLI-8M

Approx. 540 pages

CLI-8C

Approx. 830 pages

Photo chart

CLI-8BK

Approx. 1,500 pages

CLI-8Y

Approx. 320 pages

CLI-8M

Approx. 600 pages

CLI-8C

Approx. 1,000 pages

CLI-8PM

Approx. 140 pages

CLI-8PC

Approx. 220 pages

Black text: When printing the Canon standard pattern (1,500 characters per page) on A4 size plain paper, with the default

settings in the Windows XP driver, using Word 2003.

Color chart: When printing the ISO/JIS-SCID N5 pattern on A4 size plain paper in bordered printing, with the default settings

in the Windows XP driver, using Photoshop 7.0.

Photo chart: When printing the Canon standard pattern on 4" x 6" Photo Paper Plus Glossy in borderless printing, with the

default settings in the Windows XP driver, using Windows XP Photo Printing Wizard.

The print yield in the table above is an average value measured in continuous printing, using the ink tank immediately after it is

unsealed, until the ink is out. Ink yield may vary depending on texts and photos printed, application software, print mode, and

type of paper used.

When the machine is turned on and while printing, each ink may be used for protecting the print head and maintaining print

quality.

1-4. Special Tools

1-5. Serial Number Location

On the carriage flexible cable holder (visible on the right of the carriage after the machine is turned on, the scanning unit is opened,

and the carriage moves to the center).

Name

Tool No.

Application

Remarks

FLOIL KG-107A

QY9-0057-000

To be applied to the sliding portions of the carriage shaft and lift cam

shaft.

In

common

with the

S500 and

S520.

1-3

Содержание PIXMA MP950

Страница 5: ...Part 1 MAINTENANCE ...

Страница 9: ...To the table of contents To the top Part 1 1 MAINTENANCE 1 4 ...

Страница 15: ...To the table of contents To the top Part 1 2 LIST OF ERROR DISPLAY INDICATION 1 10 ...

Страница 40: ...Part 2 TECHNICAL REFERENCE ...

Страница 45: ...3 PRINT MODE 3 1 Normal Color Printing via Computer 3 2 Normal Grayscale Printing via Computer 2 5 ...

Страница 47: ...3 7 Copying 4 SCANNING 2 7 ...

Страница 48: ...To the table of contents To the top Part 2 3 PRINT MODE 2 8 ...

Страница 52: ...Part 3 APPENDIX ...