(8/23)

4. SERVICE MODE

To conduct the following functions, a host computer (Windows 98 / ME / 2000 / XP), printer driver and

service tool (QY9-0068) for the iP2200, iP1600, and iP1200 are needed (though the stand-alone print

function is available).

If an error has occurred in the printer, the service tool cannot be used as it is. To use the service tool,

set the printer in the special mode, following the procedures below.

<Special mode setting procedures>

With the ink cartridges installed, while pressing and holding the Power button, connect the AC plug.

After the Power LED lights in green, with the Power button still pressed, press the Resume/Cancel

button 2 times, and release both the Power and Resume/Cancel buttons. (Each time the

Resume/Cancel button is pressed, the Alarm and Power LEDs light alternately, Alarm in orange

and Power in green, starting with Alarm LED.)

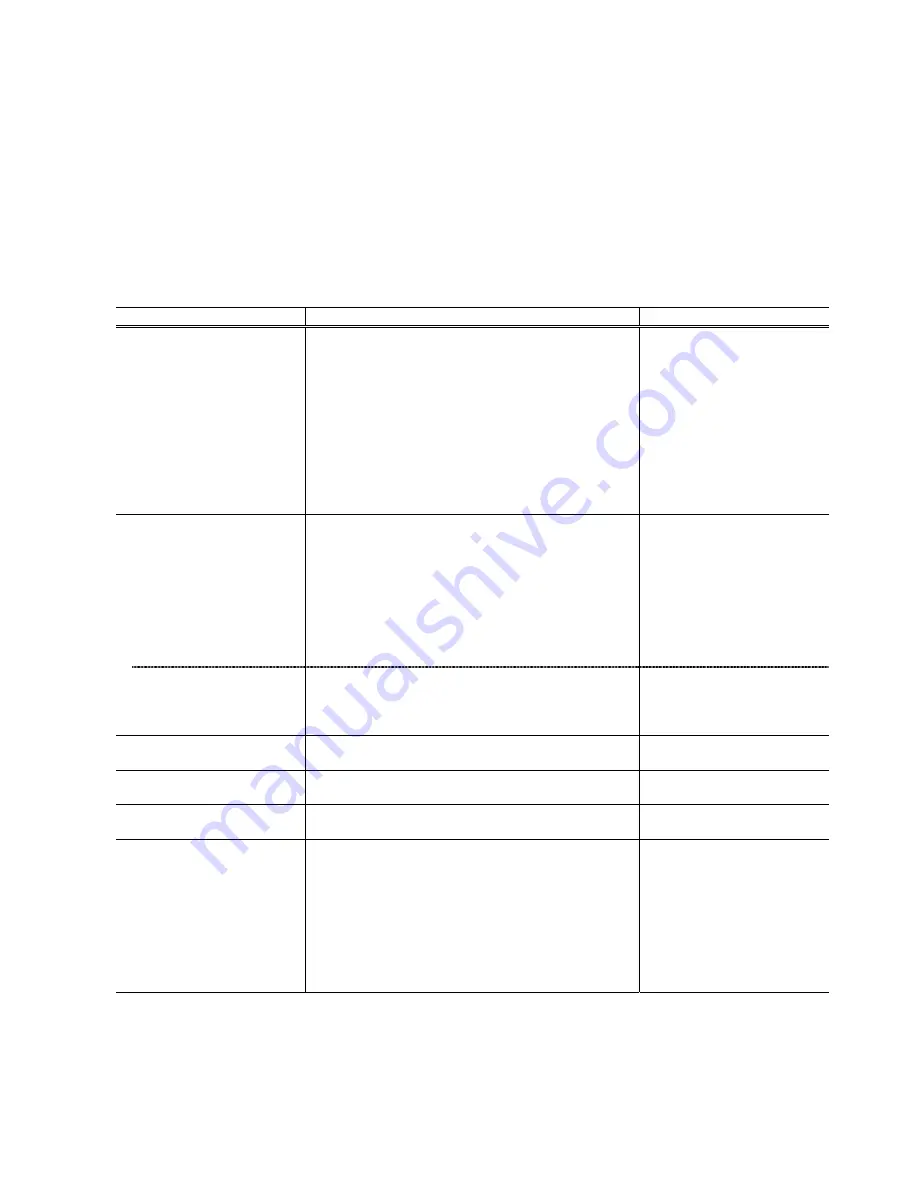

Function Procedure Remarks

Print head manual cleaning

<For reference>

Print head deep cleaning

Paper feed roller cleaning

Select “Cleaning” from the printer driver Maintenance.

Select “Deep Cleaning” from the printer driver

Maintenance.

1. Remove the paper from the ASF.

2. Select “Roller Cleaning“ from the printer driver

Maintenance.

3. Following the instruction from the Status Monitor, load 3

sheets of plain paper in the ASF, and feed them.

Cleaning time: Approx. 40 sec.

Cleaning time: Approx. 60 sec.

Cleaning time: Approx. 2 min.

Host computer is required.

Test printing

1)

Nozzle check pattern printing

<For reference>

Print head alignment

Select “Nozzle Check“ from the printer driver

Maintenance.

1. Select “Print Head Alignment“ from the printer driver

Maintenance.

2. Select the optimal value using the printed head position

adjustment pattern.

Nozzle check pattern printing

Significant misalignment can be

adjusted.

Host computer is required.

2)

Shipment pattern printing

- ROM version

- Number of pages fed

- Waste ink amount

Refer to Shipment inspection pattern*

1

below.

Refer to Shipment inspection

pattern sample*

2

below.

Host computer and service tool

are required.

EEPROM reset

(Reset of waste ink counter etc.)

Refer to EEPROM reset / Destination setting*

3

below.

Host computer and service tool

are required.

Destination setting

Refer to EEPROM reset / Destination setting*

3

below.

Host computer and service tool

are required.

EEPROM information check

Refer to Shipment inspection pattern sample*

2

below.

Host computer and service tool

are required.

Stand-alone printing

1. Set paper.

2. In the stand-by mode, press the Resume/Cancel button

5 times in 2 seconds.

<Conditions>

- At “no paper” error, turn the printer off, and turn it on

again, before doing the stand-alone printing.

- Even in the stand-by mode, if the printer enters the

power-saving mode (10 seconds after capping), the

stand-alone printing cannot be done.

Host computer and service tool

NOT required.

*

1

Shipment inspection pattern printing

a. Install the ink cartridge, and press the Power button to turn on the printer. (The Power LED lights in green.)

b. Set A4-sized paper.

c. Connect the printer to the computer. Using the iP2200 / iP1600 / iP1200 service tool (QY9-0068), select “USB

PORT.” (See APPENDIX 2, iP2200 / iP1600 / iP1200 SERVICE TOOL.)

d. Select “TEST PATTERN 1.” The printer starts printing the shipment inspection pattern.