Chapter 14

14-9

F-14-12

14.1.6 Checking the Surface Potential Control System

0015-5286

iR5065 / iR 5055 / iR5075 / / /

1. Outline

If an image fault occurs, it is necessary to find out whether the cause is in the static image formation block including the photosensitive drum and the potential

control system or if it is caused at time of development or transfer.

An image fault may be isolated by finding out whether the surface potential is correct using service mode.

2. Disabling the Auto Control Mechanisms

As a means of checking the potential control system, the auto control mechanism may be disabled (hereafter, non-auto control mode).

If the image fault in question is more or less corrected when the machine is in non-auto control mode, you can suspect the potential measurement unit and

the DC controller PCB as the cause of the fault.

You can also take advantage of non-auto control mode as a tentative remedy when the auto control mechanism has a fault.

When the machine is in non-auto control mode, all settings used for corona current control, laser power control, and developing bias control will be automatically

be set to default settings.

Using Non-Auto Control Mode

1) Make the following selections in service mode, enter '0', and press the OK key:

COPIER>OPTION>BODY>PO-CNT.

2) Press the Reset key twice.

3. Making a Zero-Level check

A "zero-level check" is a check made to see if the control mechanism of the DC controller PCB is identifying a 0-V level without fail when the drum surface

potential is 0 V.

A zero-level check may be made in either of 2 ways, and you can use it to decided whether the DC controller PCB and the potential measurement PCB is free

of error:

Method 1: use it to find out if the level shift circuit on the DC controller PCB is free of a fault

Method 2: use it to find out if the potential control circuit is free of a fault

(1) Method 1

1) Turn off the main power switch.

2) Remove the upper rear over.

3) Short GP33 on the DC controller PCB and GND using a cable equipped with an alligator clips or probes on both ends.

When shorting CP33 and GND, take full care to avoid contact between the clip/probe and the pattern of the PCB and other elements.

4) Remove the left cover (upper), delivery cover, and left cover (middle).

5) Remove the 5 screws [1], and detach the PCB cover [2].

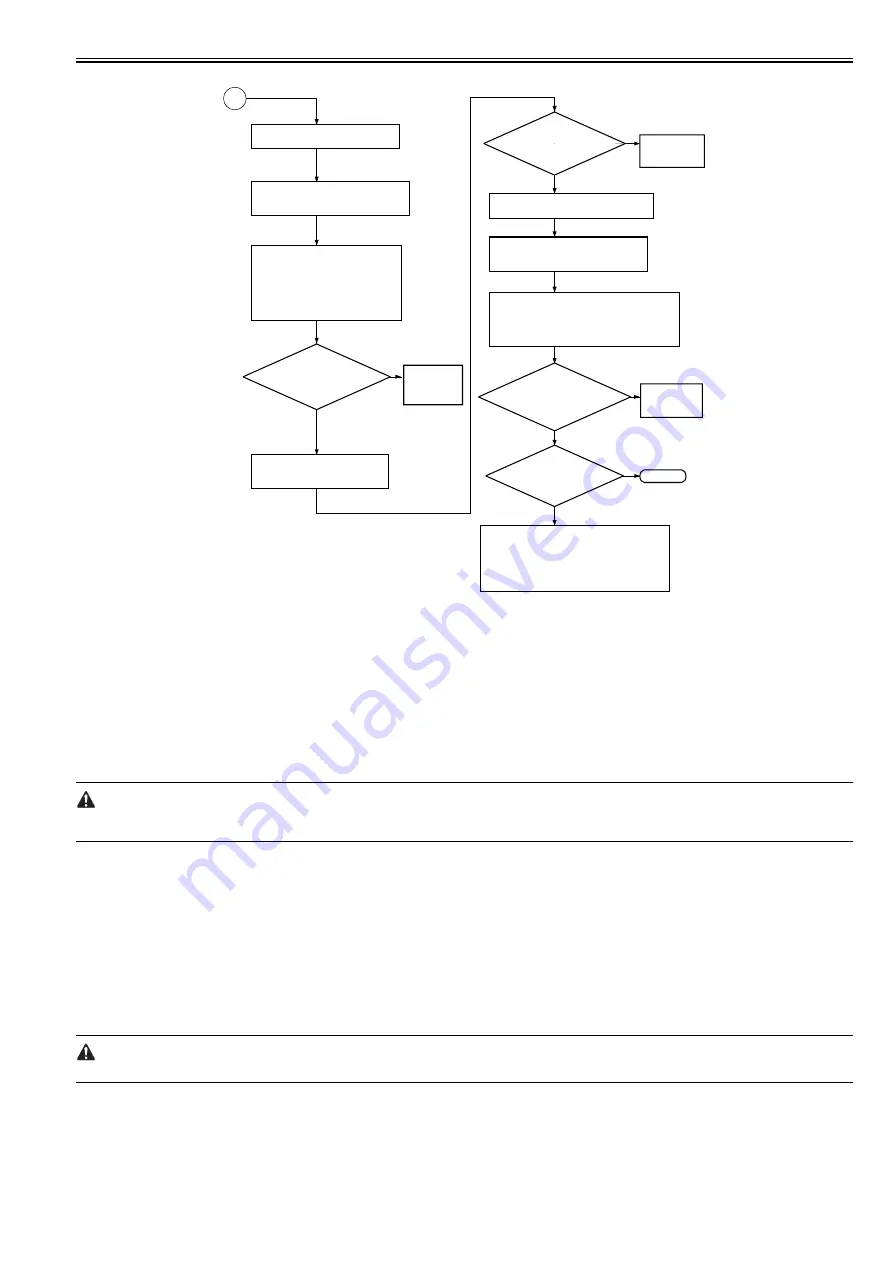

Check the developing assembly

for leakage; if normal, go to a

check on the transfer output.

Make the following selections (DC

value of the developing bias):

COPIER>DISPLAY>HV-STS>BIAS.

Covert the indication during printing

(V) into a control voltage with

reference to "Potential Control

Conversion Table."

Is the

deferense between

the actual measurement of

HVT_DEV-BIAS_DC and 'BIAS'

in service mode

± 10%?

YES

NO

Checking the Developing Bias Output

1) Check the transfer charging assembly for

leakage.

2) Make the following selections in service

mode, and try changing the setting:

COPIER>OPTION>BODY>FUZZY.

3) Try replacing paper.

Make the following selections in service mode

(level of current of transfer charging). Convert

the reading (mA) during printing into a control

voltage based on 8.5 "Potential Control

Conversion Table."

Replace the

photosensitive

drum.

NO

YES

NO

YES

NO

Is the

difference between

the measurement of HVT_

TRANSFER and 'TR' in

service mode

+/- 10%?

Checking the Transfer Output

Is the toner

image on the photosensitive

drum before transfer

normal?

Replace the

high-voltage transformer.

Is the problem

corrected?

YES

Replace the

DC controller

PCB.

Replace the

DC controller

PCB.

END

Enable potential control: COPIER>

OPTION>BODY>PO-CNT=1

B

Measure the voltage HVT_DEV_BIAS

_DC during printing of J102A-8 on the

DC controller PCB.

Disable the potential control mechanism

by setting '0' for the following:

COPIER>OPTION>BODY>PO-CNT.

Measure the voltage HVT_TRA during

printing of J102A-12 on the DC

controller PCB.

Содержание imageRUNNER 5055 series

Страница 1: ...Feb 26 2007 Service Manual iR5075 5065 5055 Series ...

Страница 2: ......

Страница 6: ......

Страница 27: ...Chapter 1 Introduction ...

Страница 28: ......

Страница 30: ......

Страница 52: ......

Страница 53: ...Chapter 2 Installation ...

Страница 54: ......

Страница 98: ...Chapter 2 2 42 ...

Страница 99: ...Chapter 3 Basic Operation ...

Страница 100: ......

Страница 102: ......

Страница 108: ......

Страница 109: ...Chapter 4 Main Controller ...

Страница 110: ......

Страница 112: ......

Страница 129: ...Chapter 5 Original Exposure System ...

Страница 130: ......

Страница 162: ......

Страница 163: ...Chapter 6 Laser Exposure ...

Страница 164: ......

Страница 166: ......

Страница 172: ......

Страница 173: ...Chapter 7 Image Formation ...

Страница 174: ......

Страница 178: ......

Страница 210: ......

Страница 211: ...Chapter 8 Pickup Feeding System ...

Страница 212: ......

Страница 263: ...Chapter 9 Fixing System ...

Страница 264: ......

Страница 268: ......

Страница 307: ...Chapter 10 External and Controls ...

Страница 308: ......

Страница 312: ......

Страница 321: ...Chapter 10 10 9 F 10 8 ...

Страница 345: ...Chapter 11 MEAP ...

Страница 346: ......

Страница 348: ......

Страница 389: ...Chapter 12 RDS ...

Страница 390: ......

Страница 392: ......

Страница 399: ...Chapter 13 Maintenance and Inspection ...

Страница 400: ......

Страница 402: ......

Страница 411: ...Chapter 14 Standards and Adjustments ...

Страница 412: ......

Страница 440: ......

Страница 441: ...Chapter 15 Correcting Faulty Images ...

Страница 442: ......

Страница 444: ......

Страница 470: ......

Страница 471: ...Chapter 16 Self Diagnosis ...

Страница 472: ......

Страница 474: ......

Страница 493: ...Chapter 17 Service Mode ...

Страница 494: ......

Страница 496: ......

Страница 552: ......

Страница 553: ...Chapter 18 Upgrading ...

Страница 554: ......

Страница 556: ......

Страница 572: ...Chapter 18 18 16 F 18 29 2 Click Start F 18 30 3 When the session has ended click OK ...

Страница 587: ...Chapter 18 18 31 F 18 59 2 Select the data to download F 18 60 3 Click Start ...

Страница 589: ...Chapter 19 Service Tools ...

Страница 590: ......

Страница 591: ...Contents Contents 19 1 Service Tools 19 1 19 1 1 List of Special Tools 19 1 19 1 2 List of Solvents Oils 19 1 ...

Страница 592: ......

Страница 595: ...Feb 26 2007 ...

Страница 596: ......