Chapter 2

2-10

2.3.2 Ink Passage

2.3.2.1 Ink Passage

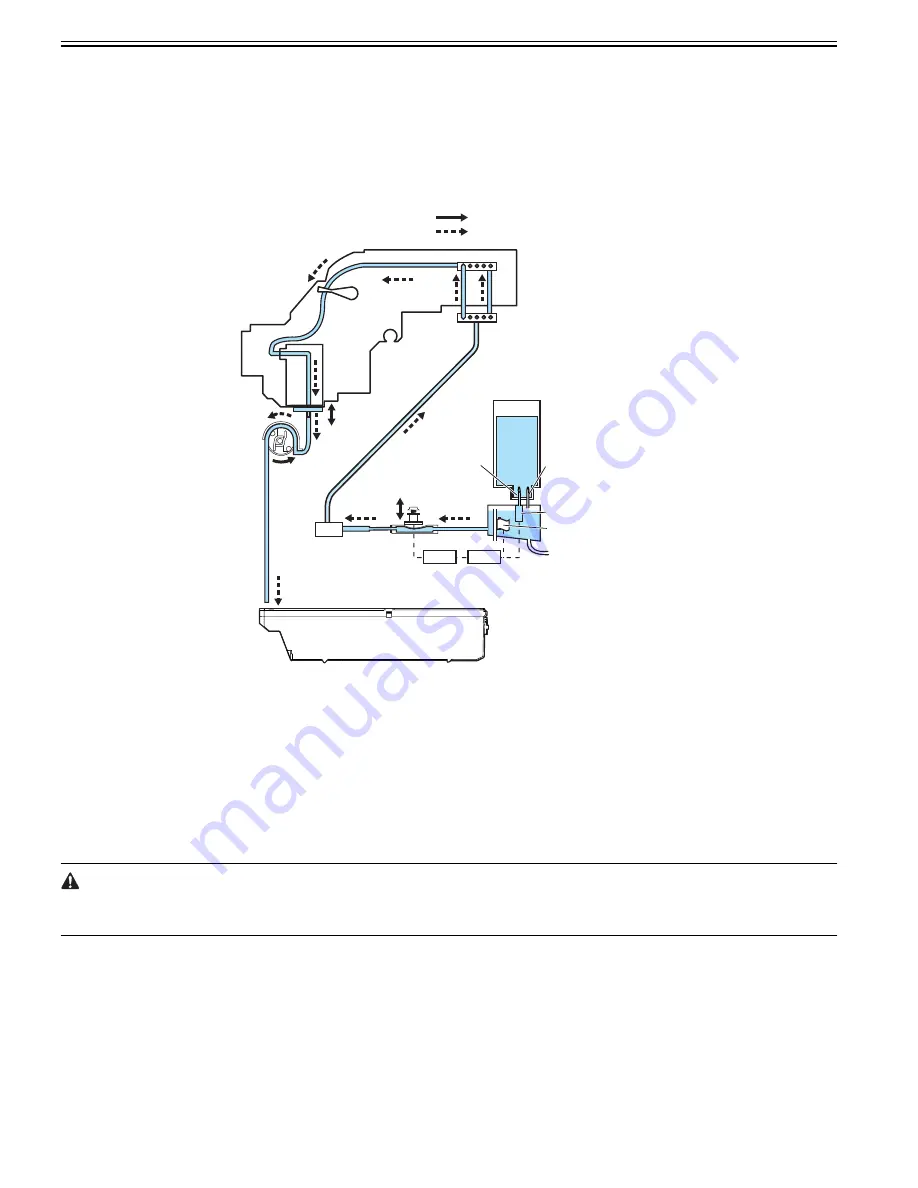

2.3.2.1.1 Overview of Ink Passage

0012-6328

The ink passage comprises ink tanks, a printheads, caps, a maintenance jet tray, a maintenance cartridge, ink tubes interconnecting the mechanical components of

the printer, and a suction pump that is driven to suck inks. It supplies, circulates, sucks and otherwise handles inks.

The ink passage (per color) is schematically shown below, along with the ink flow.

F-2-8

a) Supplying inks from the ink tanks to the ink supply valve assembly

The ink tanks each contain ink to feed the printhead.

Head differences allow the inks to flow from the ink tanks to the subtanks first, then to the ink supply valves.

Air is discharged through the air passage of the subtanks to keep the internal pressure of the ink tanks constant.

b) Supplying inks from the ink supply valves to the printhead

The ink stored in an ink tank flows to the printhead when the suction pipe is driven with the ink supply valve opened and the head capped.

c) Supplying inks while printing

The ink supply valves are kept open while printing, so that ink is constantly flowing to the printhead under the negative pressure of the nozzle assembly which is

caused by the discharging inks.

Furthermore, waste inks sucked in the cleaning operation and inks from the maintenance jet tray flow into the maintenance cartridge.

Opening all the ink passages (by opening both the ink supply valve and the printhead fixer lever with an ink tank yet to be installed) while an ink tube is being filled

with ink could cause the ink in the ink tube to flow backwards due to a head pressure difference, causing leakage through the hollow needle in the ink tank.

As a precaution, never open all the ink passages at the same time while the ink tubes are being filled with inks.

d) Ink agitating

Ink will be agitated to prevent the element of the pigment ink from subsiding in the ink tank and the sub-tank.

The valve motor drive is transmitted to the agitation cam, the agitation fin in the sub-tank rotates and ink in the sub-tank will be agitated. In addition, ink flows

backward by moving the piston under the needle(ink supply) up and down in the ink tank, and ink in the ink tank will be agitated.

Maintenance cartridge

Ink tank

Ink supply vavle

Joint

Joint

Carriage unit

Printhead

Cap

Suction pump

Mechanical Drive Unit

Ink or air flow

Subtank

Agitation fin

Needle(ink supply)

Piston

Needle(air passage)

Valve

motor

Agitation

cam

Содержание imagePROGRAF iPF8400

Страница 2: ......

Страница 6: ......

Страница 11: ...Chapter 1 PRODUCT DESCRIPTION ...

Страница 12: ......

Страница 14: ......

Страница 52: ...Chapter 1 1 38 3 Push in the left and right Basket Rods toward the back all the way until they stop F 1 36 ...

Страница 63: ...Chapter 2 TECHNICAL REFERENCE ...

Страница 64: ......

Страница 106: ......

Страница 107: ...Chapter 3 INSTALLATION ...

Страница 108: ......

Страница 110: ......

Страница 123: ...Chapter 3 3 13 F 3 22 6 FAN UNIT A ...

Страница 125: ...Chapter 3 3 15 ...

Страница 126: ......

Страница 127: ...Chapter 4 DISASSEMBLY REASSEMBLY ...

Страница 128: ......

Страница 130: ......

Страница 165: ...Chapter 4 4 35 5 Upper cover stay shaft hole 1 gear shaft 2 shaft end 3 gear tooth face 4 F 4 54 1 2 4 3 ...

Страница 167: ...Chapter 4 4 37 ...

Страница 168: ......

Страница 169: ...Chapter 5 MAINTENANCE ...

Страница 170: ......

Страница 172: ......

Страница 177: ...Chapter 6 TROUBLESHOOTING ...

Страница 178: ......

Страница 180: ......

Страница 214: ......

Страница 215: ...Chapter 7 SERVICE MODE ...

Страница 216: ......

Страница 218: ......

Страница 273: ...Chapter 7 7 55 ...

Страница 274: ......

Страница 275: ...Chapter 8 ERROR CODE ...

Страница 276: ......

Страница 278: ......

Страница 296: ......

Страница 297: ...Appendix ...

Страница 298: ......

Страница 307: ...Sep 14 2012 ...

Страница 308: ......