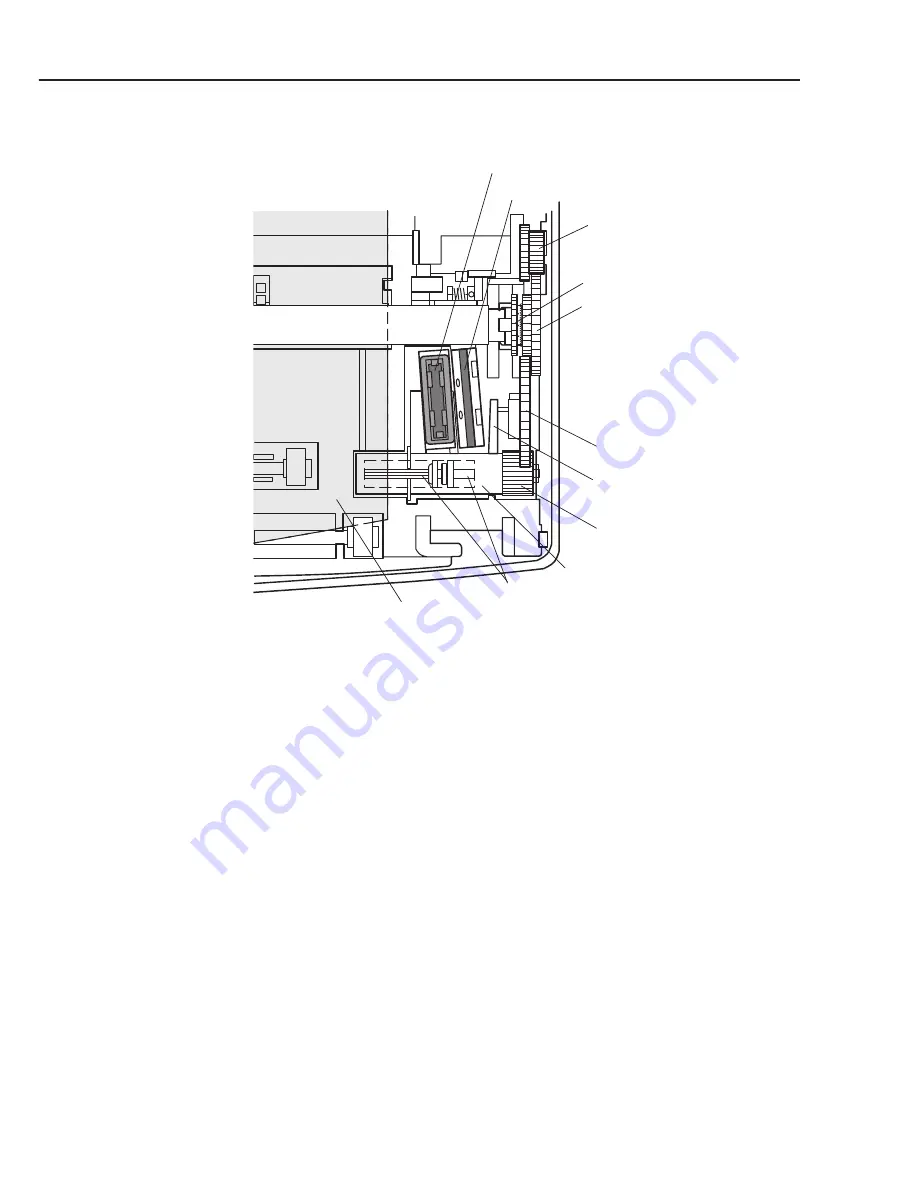

3.3 Purge Section Structure

3.3.1 Configuration

a) Cap section

When the carriage is at the home position, the cap is pressed against the print head

faceplate to cap the head. The rubber cap connects to the pump, and ink is sucked

from the head by the pump during cleaning. The sucked ink is absorbed by the ink

absorber in the pump and finally collected in the waste-ink absorber. The cap is

moved by the p pump arm, which is driven by the pump gear. Therefore, the

b) Wiper section

The wiper wipes excess ink off the print head faceplate when the carriage moves

from left to right. The wiper is moved up or down by the projections on the carriage.

The ink attached to the wiper is removed by the aluminum plate on the head.

Moreover when the wiper comes down, the ink remaining on it is splashed on the

pump gear.

c) Pump section

The pump contains a rubber piston, whose piston shaft is linked with the cylinder

gear. The cylinder gear is rotated by the pump gear. Then the pump is opened to

absorb the ink collected in the cap into the waste ink absorber. The ink in the cap

flows into the absorber in the pump, and then into the waste ink absorber.

d) Waste ink absorber

The ink sucked from the cap and the ink collected in the pump are sucked into the

absorber in the pump, and absorbed into the waste-ink absorber.

Part 4: Technical Reference

BJC-50

4-28

Paper Feed W-gear

Trigger Gear

Paper Feed Gear

Pump Gear

Pump Arm

Cylinder Gear

Waste Ink Absorber

Pump

Cap

Wiper

Piston Shaft

Figure 4-21 Purge Section Structure

Содержание BJC-55 Series

Страница 1: ...BJC 55 SERVICE MANUAL Canon...

Страница 34: ......

Страница 50: ......

Страница 72: ...2 4 Character Code Tables Code page 437 Code page 850 Part 2 Product Specifications BJC 50 2 22...

Страница 73: ...Code page 860 Code page 863 2 23 BJC 50 Part 2 Product Specifications...

Страница 74: ...Code page 865 Code page 857 Part 2 Product Specifications BJC 50 2 24...

Страница 75: ...Code page 855 Code page 852 2 25 BJC 50 Part 2 Product Specifications...

Страница 76: ...Code page 864 Code page 869 Part 2 Product Specifications BJC 50 2 26...

Страница 78: ......

Страница 96: ...3 4 1 Demonstration print Part 3 Operating Instructions BJC 50 3 18 Figure 3 13 Demonstration Print Sample...

Страница 103: ...3 6 4 EEPROM settings list print 3 25 BJC 50 Part 3 Operating Instructions Figure 3 20 EEPROM Settings List Print Sample...

Страница 106: ...Part 3 Operating Instructions BJC 50 3 28 This page intentionally left blank...

Страница 108: ......

Страница 160: ......

Страница 164: ...4 ADJUSTMENT No parts need to be adjusted Part 5 Maintenance BJC 50 5 4...

Страница 198: ...7 CIRCUIT DIAGRAMS 7 1 Parts Layout 7 1 1 Control board Upper section Part 5 Maintenance BJC 50 5 38...

Страница 199: ...7 1 2 Control board Lower section 5 39 BJC 50 Part 5 Maintenance...

Страница 200: ...Part 5 Maintenance BJC 50 5 40 This page intentionally left blank...

Страница 206: ...PRINTED IN JAPAN IMPRIME AU JAPON CANON INC The printing paper contains 70 waste paper...