1-3/4”

(44 mm)

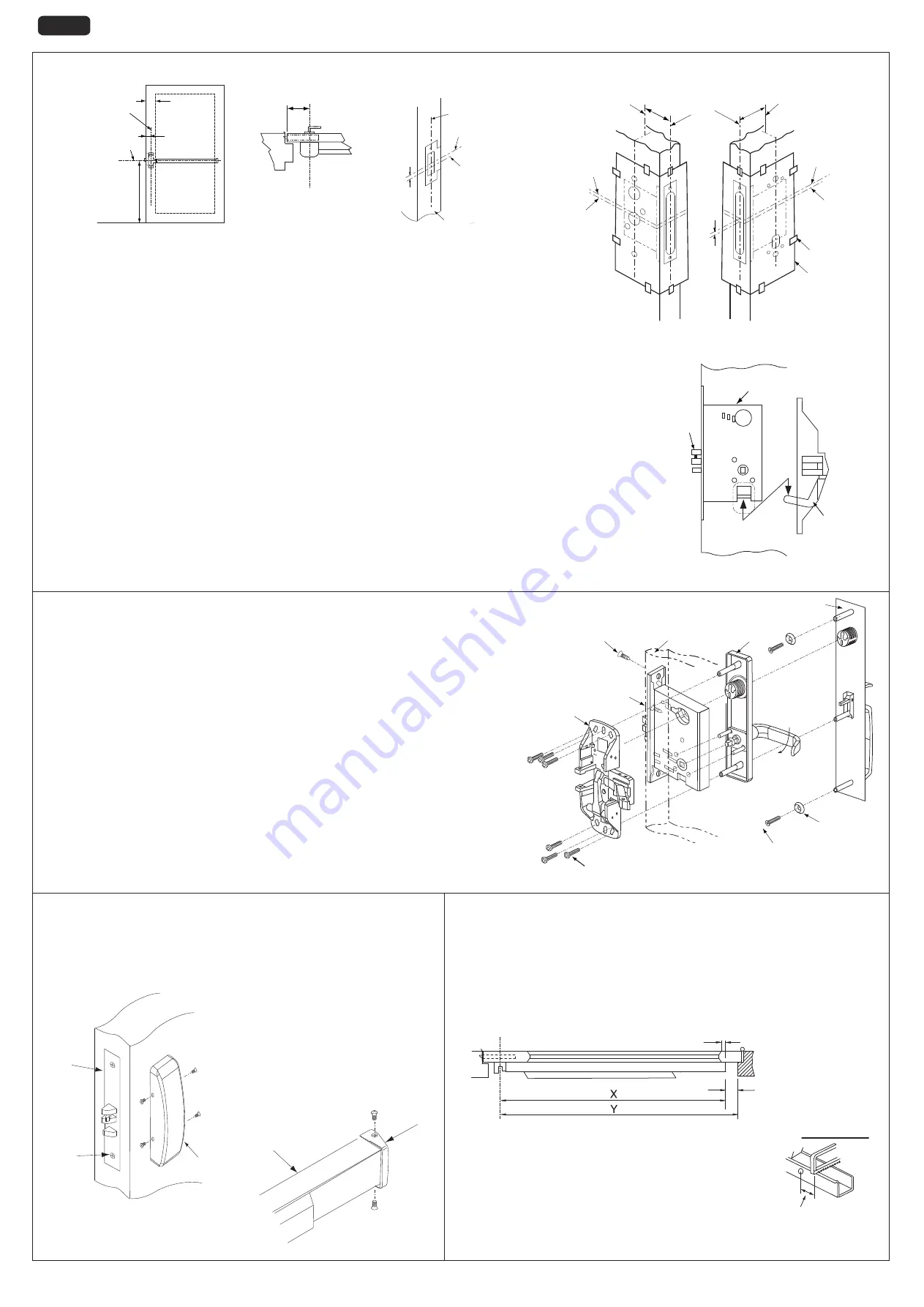

Provide minimum 1/2

“ (12.7 mm) overlap

with rail

backset & chassis

vertical reference line

single door (LHR)

Stile Width

Chassis vertical

centreline

Chassis horizontal

centreline

2 3/4” (70 mm) backset

2 3/4” (70 mm)

Backset

2 3/4” (70 mm)

Backset

2-3/4” (70 mm)

Backset

Backset & chassis

vertical reference line

INSIDE DOOR

SURFACE

Chassis Horizontal

Centreline

Chassis Horizontal

Centreline

Mortise Lock

Horizontal

Centreline

Mortise Lock

Horizontal

Centreline

Chassis Vertical

Centreline

Chassis Vertical

Centreline

Door Thickness

Vertical

Centreline

OUTSIDE DOOR

SURFACE

Strike Horizontal

Centreline

Mortise Lock

Horizontal Centreline

Strike Vertical

Centreline

Door Frame

3/8”

(9.5 mm)

Machine

screws

Mortise lock

faceplate

#10-24 Machine

Screw

Cup Washer

REFERENCE

40-3/16”

(1021 mm)

5-1/2”

(140 mm)

3/8”

(9.5 mm)

Cut off & deburr

Don't cut closer than 1 3/4"

(44 mm)

from lower pivot

(remove sliding cover to locate pivot)

Main chassis

cover

End Cap

Mounting Rail

Cover

machine screws

Machine screws

Finished Floor

Latch

Lock body

Latch

retraction

Chassis

lever arm

Finished floor

Door

#14 Combo

Screws

Cylinder screw

Escutcheon

Trim

Gripset Trim

Chassis

#10-24, Pan Head

Machine Screws

Template

Tape

Door

Edge

Door

Edge

9500M

SERIES

2. EXIT DEVICE, MORTISE LOCK, TRIM & STRIKE INSTALLATION

A. GENERAL NOTES:

1. It is recommended to prepare the door and door frame for the mortise lock at the door fabrication shop.

2. Supplied installation instructions and templates are for wood door/frame applications. Metal door/frame applications will require appropriate door

reinforcement, door edge and frame preparation to accommodate the mortise lock and strike.

3. Surface on which the exit device will be installed must be flush and flat within 1/32” (0.8 mm).

4. It is important that all hole positions must be precise within 1/32” (0.8 mm).

5. The door stile width must be at least 5-1/2 (140 mm)” wide.

6. Study all supplied instructions and templates prior to start of drilling.

B. MORTISE LOCK AND TRIM

1. Determine the lock’s horizontal and vertical (backset) centrelines. NOTE: the lock’s horizontal centreline is 3/8” (9.5 mm) above the exit device

chassis horizontal centreline. The exit device mortise latch horizontal centerline is recommended to be located approximately 40-5/16“ (1023 mm)

above the finished floor.

2. Prepare door edge for the lock body using supplied template and dimensions.

3. Prepare outside door surface for the applicable trim using supplied trim template and dimensions.

4. Drill the trim mounting holes per applicable trim.

5. If required, Drill the cylinder hole only on the door outside surface.

C. EXIT DEVICE CHASSIS

1. Using the supplied template, mark and cutout hole on door interior surface for exit device lever arm.

2. Prior to drilling holes for the main chassis, verify that the exit device can activate and fully retract the mortise lock latch.

a. Temporarily fasten lock body into the door edge cavity and place the exit device flat on the door.

b. With push pad released (not pressed), ensure that the exit device chassis lever arm just touches the lock body (see Detail “A”) and does not

retract the latch.

c. With the push pad depressed, ensure that the mortise latch is fully retracted. Mark the chassis position and mounting holes.

3. Or prepare the chassis mounting holes using supplied template and dimensions (if preparing door in advance).

4. Remove lock body (if attached to door) and drill the required holes for the chassis.

5. Ensure holes in chassis align with holes in the trim post (If not, adjust slot height in exit device chassis). Refer to pictorial in section 2.

D. STRIKE

1. The strike horizontal centreline must be 3/8” (9.5 mm) higher than the lock centreline.

2. Position the strike vertical centreline as per supplied template and mark the strike outline on door frame.

3. Recess the door frame strike cutout depth as per template and depending if dust box is used.

4. Pre-drill in wood frame or drill and tap in metal frame for the strike mounting screws.

NOTE: Metal frames require appropriate preparation for the strike mounting. Refer to ANSI A156-115 or consult your mortise lock exit device supplier.

A. INSTALLATION

1. Verify that the mortise lock handing is appropriate for the installation. Reverse handing if required as indicated on sheet 1.

2. Insert the mortise lock into the door edge cavity and temporarily fasten with mounting screws.

3. Insert exterior trim into prepared holes on the door’s exterior surface, then follow the installation instructions supplied with trim.

4. Install mortise cylinder and secure with cylinder screw. NOTE: Lock body dictates the position of the trim posts and exit device chassis.

5. Place exit device chassis on the door’s inside surface, ensure that the chassis lever engages properly with the lock and retracts the

latch. Fasten the chassis and trim using supplied machine screws. Verify that trim operates latch as per trim function.

6. Attach the chassis to door surface with #10 pan head wood or #10-24 machine screws.

7. Level the mounting rail, then mark and drill holes for the rail mounting bracket and fasten to door with supplied screws.

8. Tighten all mounting screws.

9. Install strike and dust box and fasten using supplied screws.

B. VERIFICATION

1. Verify that the exit device retracts the mortise lock latch when push pad is depressed and engages properly with strike.

2. Verify the lock function.

3. Verify that the trim operates the mortise lock and retracts the latch.

4. Ensure that there is no binding once all screws are tightened.

5. If lever does not spring back after it is pressed down, ensure that the all posts in the door holes have not been distorted due

to holes misalignment. Provide sufficient clearance for all holes.

4. RAIL MODIFICATION AND INSTALLATION

3. FACEPLATE & COVER INSTALLATION

1. Verify that all mounting screws are sufficiently tightened.

2. Install and attach the lock body faceplate.

3. Install and attach the main chassis cover.

4. Install and attach the railing end cap.

1. Confirm length of device and determine if cutting is required

2. Determine length 'X' by subtracting 1 3/4" (45mm) from 'Y'

Mark cut-off point on rail and sliding cover and cut-off

3. Deburr edges of rail and sliding cover and install as per Section 2

9500M-INS-EN-2015-02

2/2

1. PREPARE DOOR AND DOOR FRAME FOR MORTISE LOCK EXIT DEVICE

MORTISE LOCK EXIT DEVICE (FIRE) - INSTALLATION INSTRUCTIONS

LEFT HAND REVERSED SHOWN

DETAIL “

A

”

LEFT HAND REVERSED SHOWN