18

Section 3

Model 289A Differential Pressure Indicating Switch

4. Check the pointer for zero indication. If necessary, set the pointer to zero

by slipping the pointer on the hub, per

Calibration Check

, step 2,

page

15

.

5. Apply 100% pressure. If the pointer exceeds full-scale, lengthen the

movement range arm by adjusting the range adjust screw with a 1/8-in.

open-end wrench.

6. Release pressure. Set the pointer to zero, by slipping the pointer on the

hub, per

Calibration Check

, step 2,

page 15

.

7. Repeat steps 4 and 5, as necessary, to obtain the correct zero/full-scale.

8. Apply 50% DP. If the pointer indicates 50%, proceed to step 9. If the

pointer does not indicate 50% scale, adjust linearity as follows.

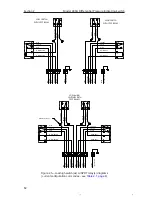

a. Loosen the drive arm screw (Figure 3.5) and move the arm to shift

the pointer in the direction of the error a distance of about 10 times

the linearity error.

b. Check to see that the drive arm clears the end of torque-tube housing

by approximately 0.030 in. before retightening the drive arm screw

to prevent interference.

c. While supporting the block/shaft, tighten clamp screw until snug to

shaft.

d. Still supporting block/shaft, tighten clamp screw an additional 1/3

to 1/2 turn. (This screw can normally turn one full revolution before

breaking.)

e. Perform the Drive Arm Tightness Test described on

page 19

.

1/8” WRENCH

(PN 9A-0163-0044C)

CLAMP SCREW

DRIVE ARM

LINK

SINTERED

CLAMP BLOCK

TO TIGHTEN

.03 (approx)

M224

SHAFT

Figure 3.5—Drive arm to torque tube connection

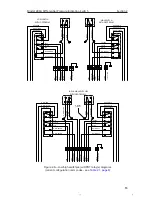

9. Release pressure and reset the pointer at zero. Check the span. If the gear

in the movement reaches a limit of travel as a result of linearity adjust-

ment (step 7), slip the range arm along the gear approximately 5 degrees

from the normal 37.5 degree angle to approximately 43 degrees (see step

2). The range arm is slipped by applying pressure to the range arm with

Содержание BARTON 289A

Страница 75: ...R U S S I A ms kl c a m com 603 5569 0501 ...