P.

1

5

15

-

M

an

u

al

c

od

e:

11

9

A

V

7

0

11

9

A

V

7

0

ve

r.

1

.1

1.

1

08

/2

0

11

© C

A

M

E c

an

ce

lli

auto

m

ati

ci

s.p.a. - T

h

e d

ata a

n

d i

nf

or

m

ati

on i

n th

is

m

an

u

al

m

ay b

e c

h

an

g

ed at a

ny ti

m

e a

n

d w

ith

ou

t o

b

lig

ati

on

o

n th

e p

art of C

am

e C

an

ce

lli

A

uto

m

ati

ci

S

.p.a. to n

otify s

ai

d c

h

an

g

es.

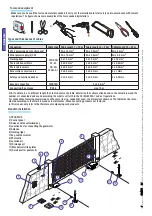

ENGLISH

Check that there is no vegetation within range of the photocells, and that no objects interfere with the operation of the automated

gate.

PROBLEMS

POSSIBLE CAUSES

CHECKS AND FIXES

The gate neither

opens nor closes

No power supply

The gearmotor is released

The tramitter battery is run down

The tramsitter is out of order

• The stop button is stuck or broken

The opening/closing button or key-switch selector are broken.

Check power supply

• Call for assistance

Replace batteries

• Call for assistance

• Call for assistance

• Call for assistance

The gate opens but

does not close

The photocells are engaged

• Check that photocells are cle-

an and in proper working order

• Call for assistance

The flashing light

does not work

Light bulb is burned

• Call for assistance

Troubleshooting

Date

Notes Signature

Periodic maintenance log to be done by users (every 6 months)