Entering programs and settings

Controller operation is based on an internal clock with calendar and automatic time adjustment.

By navigating through the appropriate menu items and using the buttons on the front panel (“MENU”.

“UP”

, “DOWN”

, and “OK”), the user can configure the controller, set the various parameters,

and display the temperature log.

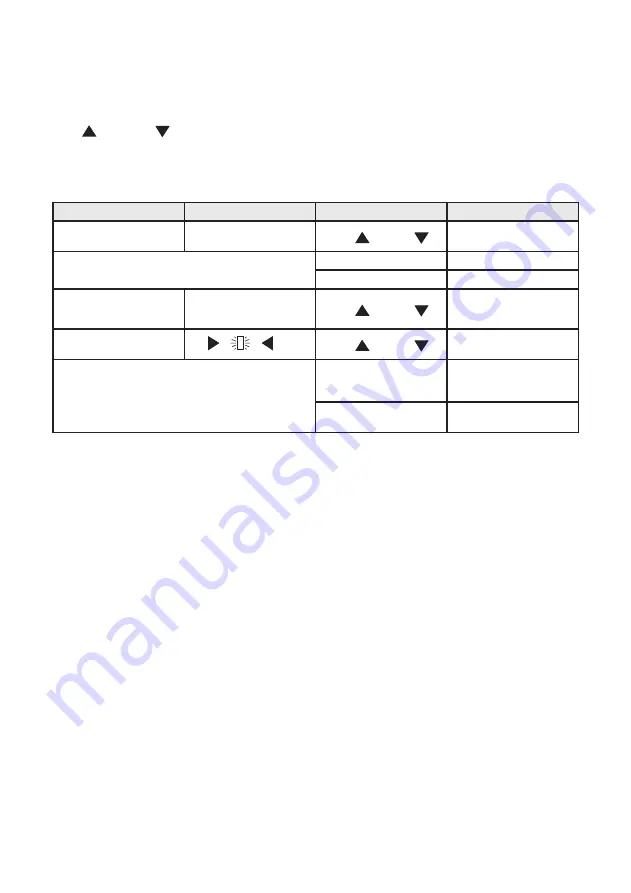

Functions of the configuration buttons

Description

Display

Button function

Effect

Menu item - arrows beside

the row

“UP”

,

“DOWN”

Moves the cursor to another

row

+OK

Opens the related submenue

Menu

Go back to previous level

Other rows available

-arrows in the screen margin

“UP”

,

“DOWN”

Displays other rows in the

menu

Parameter selection

-cursor flashing

“UP”

,

“DOWN”

Increases or descreases the

parameter value

+OK

Confirms the setting - cursor

disappears and the value

becomes actual

Menu

Return to previous level

without making changes

Whatever status the controller is in (except Low Power), navigation around the various menus to read

the various settings and view the stored log data is always possible. However, for safety purposes,

the

settings data can be modified only when the controller is in “Adjustment” mode.

In particular,

parameters can not be modified while the controller is in “disinfection”, “flux” or “thermal shock” mode,

and when the controller is in the “inactive with alarm” status. The various options are made availalble,

depending on whether the return water temperature sensor has been enabled. To set programs 1B or

2, the return water temperature sensor must be set as Present. To be able to remove the return water

temperature sensor (i.e. set it as Present of Absent), program 0 or 1A must be set first.

Remote control

The controller can be controlled from a remote computer with the RS485 serial output connection, which

can be accessed by hard-wired terminals and through the connector on the front panel. Since the interface

is the multipoint bus type it is necessary for each controller connected on the bus to be identified by

an appropriate address to avoid identification conflicts. For a detailed description of the operations and

controls that are available from a remote location using this interface, refer to the relevant documentation.

Contact Caleffi for list of registers (points) for mapping LEGIOMIX information to ModBus. Configuation,

mapping, hardware (routers, modem, etc.), and software are customer/user responsibility. Code NA10520

Modbus-to-BACnet gateway is available separately for translating ModBus to BACnet.

19