9

Actuation relays

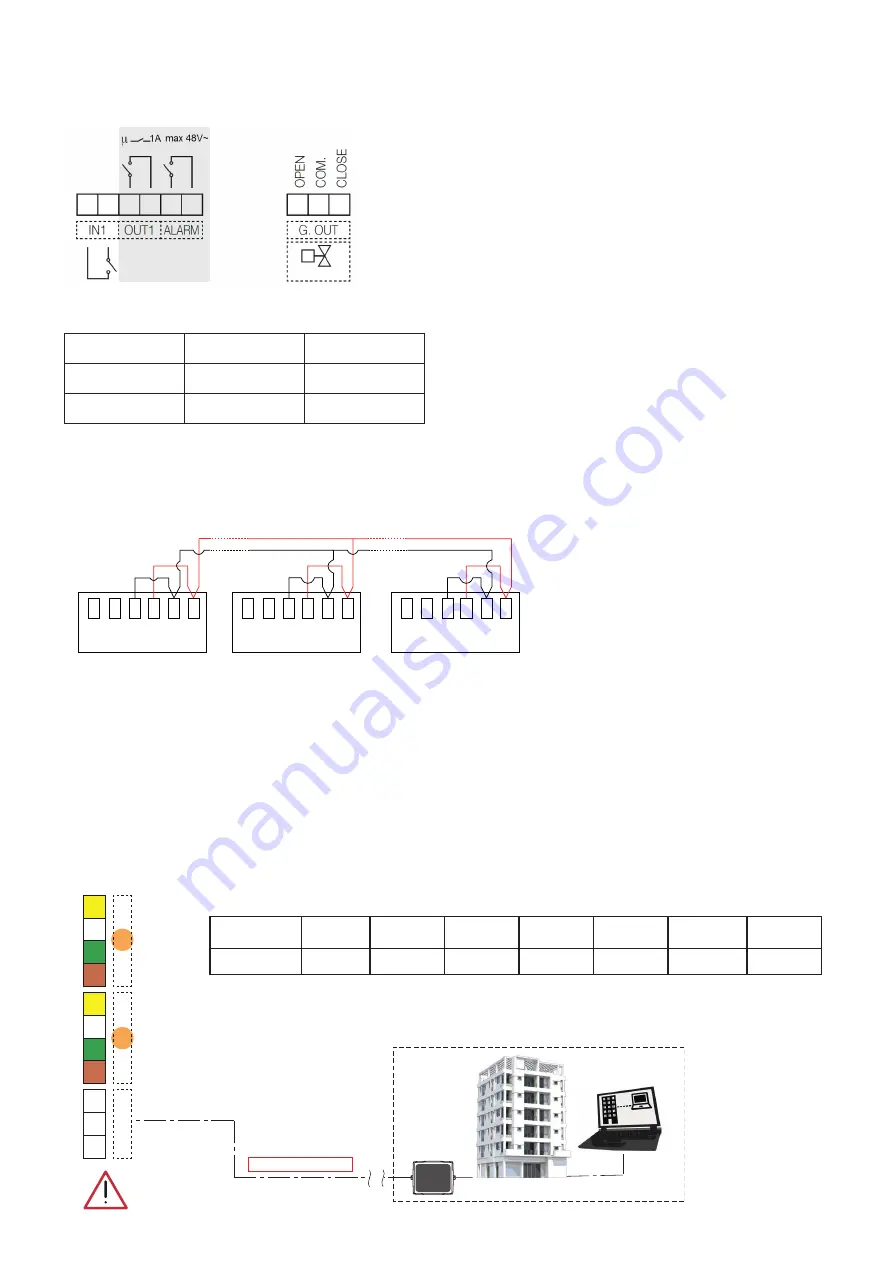

The board features the auxiliary replay contacts used to control auxiliary equipment and alarms.

IN1

input relay for voltage free contact. When the contact is closed, strainer

cleaning is inhibited

OUT1 relay output N.A. The contact closes when the strainer is in the cleaning

phase (max 48V,1A)

ALARM relay output N.A. for alarms indication (48V, 1A max)

G. OUT output for control of cold water injection valve on drain (max 5(2)A 250V).

The relay can drive a motorised diverter valve with 3-contact command.

MAINS LOSS

SIGNAL ACTIVE

OUT1

Open

Closed

ALARM

Open

Closed

Operation in parallel

Two or more strainers can be connected in parallel to increase the filtration capacity of the system, in cases in which there is no bypass provided

and the application calls for continuous service. Make sure however, that the cleaning phase does not occur at the same time. For this reason, if it is

detected that another device connected to the strainer is in the active phase, the system waits until the device in question is no longer operating. For

simple hook-up of the parallel connection of multiple devices (up to a maximum of 10), the following wiring diagram can be used:

MAX10

IN1

OUT1

ALARM

IN1

OUT1

ALARM

1

2

3

4

5

6

1

2

3

4

5

6

IN1

OUT1

ALARM

1

2

3

4

5

6

This connection can be made using a shielded twisted pair with minimum conductor size of 0.5 mm

2

. Maximum length of connections between one

device and another is 2.95 m. The cable must be routed through data trunking carrying only very low voltage cables. During operation, with a direct

connection between OUT1 and IN1, when a controller performs a cleaning cycle, its display shows a flashing “I” message to indicate that contact

IN1 is closed.

IMPORTANT! Comply with the wiring diagram and do not invert connections 1 – 2 from one device to the next.

Operation not recommended in the case of activation of the cleaning cycle by means of

D

p. Enabling preferable via programmed

cleaning; in the case of an electric supply loss of one of the strainers it is not possible to guarantee correct operation of the system:

the other strainers will be inhibited.

Remote control via MODBUS

Make the connection using the “BUS” terminals:

BMS

RS485/MODBUS-RTU

A

B

BUS

SCH

-

2

1

+

S2

-

2

1

+

S1

Protocol type

BUS

Baud Rate

Data bit

Parity

Stop bit

Handshake

Unit Load

MODBUS-RTU

RS-485

9600

8

EVEN

1

None

1/8 UL

Transmission

Actuator relay status summary table:

With this connection, if one of the dirtmagclean

units performs a cleaning cycle or assumes alarm

status, a flashing "I" message will be shown on all

the devices and cleaning of the other strainers is

inhibited until the device, in cleaning status or alarm

mode, resumes its normal operation or filtration.

Содержание DIRTMAGCLEAN 579 Series

Страница 14: ...14...