© Copyright 2017 Caleffi

H0000741.01

www.caleffi.com

INSTRUCTIONS FOR INSTALLATION,

COMMISSIONING AND MAINTENANCE

Thank you for choosing our product.

Further technical details relating to this

device are vailable at www.caleffi.com

MOTORISED BUTTERFLY VALVE,

WAFER TYPE

Warnings

The following instructions must be read and understood before

installing and maintaining the product. The symbol

means:

CAUTION! FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN A SAFETY HAZARD!

Safety

The safety instructions provided in this document must be

observed.

LEAVE THIS MANUAL AS A REFERENCE GUIDE

FOR THE USER

DISPOSE OF THE PRODUCT IN COMPLIANCE

WITH CURRENT LEGISLATION

Function

The motorised, wafer type, butterfly valves can be used on

heating and air-conditioning systems as zone or shut-off

devices. Thanks to their compact body, they need reduced

spaces for the installation.

Technical specifications

Materials

Body:

cast iron EN-GJL-250C EN 16482

Control stem:

stainless steel EN 10088-3 (AISI 420)

Butterfly:

cast iron

EN-GJS-400 15C EN 16482

Butterfly seal:

EPDM

Control stem seal:

EPDM

Performance

Medium:

water, glycol solutions

Max. percentage of glycol:

30%

Max. working pressure:

16 bar

Max. differential pressure:

6 bar

Flanged connections:

PN 16

Can be coupled with EN 1092-1 counterflange

Conformity:

directive PED 2014/68/EC

(97/23/EC until July the 18

th

2016)

directive 2006/42/EC

Face to face distance:

EN 558-1 ( DIN 3202 T3 K1)

ISO 5752 T5

Upper flange:

EN ISO 5211

Ambient conditions

(valve + actuator)

Medium working temperature range:

-10–95°C

Ambient temperature:

- Operation:

-10–65°C EN 60721-3-3 Cl. 3K4,

max. humidity 95%

- Transportation:

-30–70°C EN 60721-3-2 Cl. 2K3,

max. humidity 95%

- Storage:

-20–70°C EN 60721-3-1 Cl. 1K2,

max. humidity 95%

Actuator technical specification

Synchronous motor three point type

Electrical supply:

230 V (ac), 24 V (ac)

Power consumption:

- DN 32–DN 80:

4,5 VA

- DN 100–DN 200:

10,5 VA

Auxiliary microswitch contact rating:

- DN 32–DN 80:

16 (4) A - 250 V (ac)

- DN 100–DN 200:

16 (6) A - 250 V (ac) - double switch

Protection class:

- DN 32–DN 80

IP 42

- DN 100–DN 200

IP 65

Operating time:

180 s (rotation 90°)

With manual opening system.

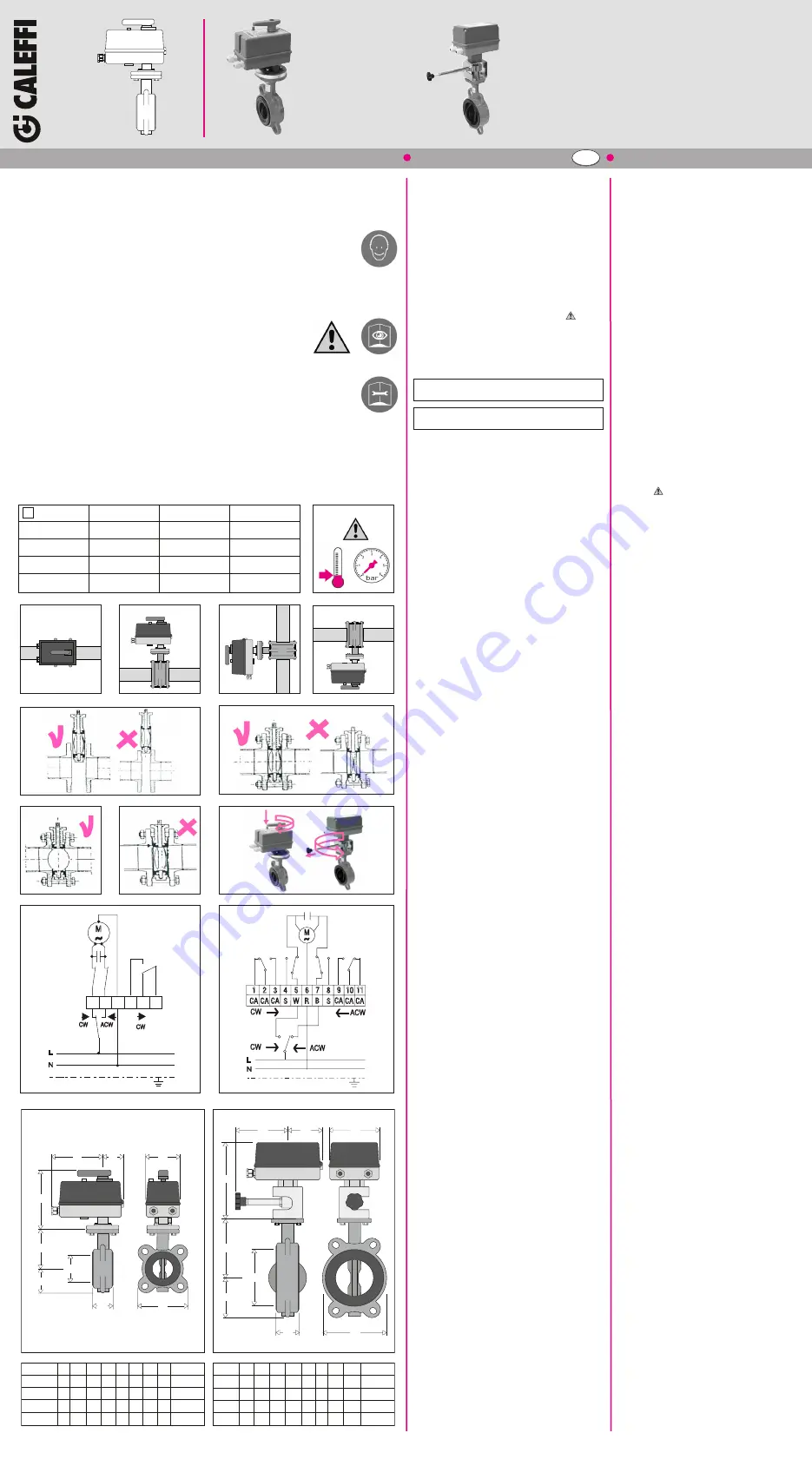

Hydraulic characteristics (fig. A)

Installation (fig. B – C – D – E – F - G - H - I - L)

Assembly and disassembly should always be carried out while

the system is cold and not in pressure (fig. B).

The butterfly valve is bidirectional and can be mounted in the

following ways:

• the recommended position is on horizontal pipe with

the actuator laying on the side (actuator axis in horizontal

position), with the lower part of the butterfly opening from

upstream to downstream (fig. C);

• on horizontal pipe with the actuator in vertical position

above the valve body (fig. D). The actuator should never be

installed upside down (fig. F);

• on vertical pipe, with cable glands pointing downward

(fig. E).

Compatibility with pipes and flanges

Check that the flange diameter allows the butterfly rotation.

The valves are intended for fitting between collar and flanges.

Installation on pipe

General: the valve should not be used to separate the flanges

to be inserted within, otherwise the seal can get damaged

(fig. G). Separate the flanges by means of a specific tool in

order to obtain a distance between the flanges which is

suitable for the valve insertion without forcing.

Installation on existing pipe

1. The valve should be installed between the flanges without

difficulty. Separate the flanges by means of a specific tool.

Flanges not perfectly separated could damage the gasket

or butterfly during the insertion of the valve (fig. G).

2. Close the butterfly so that it is about 5-10 mm inside

the valve body. A fully open butterfly could in fact get

damaged by scraping against the flanges.

3. Position the valve between the flanges. Centre the valve

body and put in all the bolts.

4. Completely open the valve.

5. While z the valve correctly aligned with the flanges, and

removing the tool used to separate them, screw the nuts

by hand (fig. H).

6. Carefully close the valve and check that the butterfly

rotates freely.

7. Completely reopen the butterfly and fully screw the nuts.

The bolts should be fully screwed with the valve in fully

open position, otherwise the gasket could be compressed

in not optimum conditions. This could result in too high

closing torque or leakage (fig. I). Do not use o-ring or grease

(fig. L).

Installation on new pipe

1. With the butterfly almost closed, put the two flanges on the

body with a few bolts. Close the tap between the flanges.

2. Install everything on the pipe.

3. Fix the flanges to the pipe with a few welding spots.

4. Undo the nuts and remove the valve from the flanges.

5. Complete the welding of the flanges and allow to cool

completely.

6. Refit the valve as described above in the section

“Installation on existing pipe”.

DO NOT COMPLETELY WELD THE FLANGES WITH THE

VALVE FITTED AS THIS COULD DAMAGE THE GASKETS.

ENGLISH

EN

Manual opening /closing (fig. M)

After cutting off the electric supply, it is possible to open/close

manually the valve by means of the specific manual command.

On DN 32-80 sizes, press the clutch button and rotate the lever

(both are located on the actuator cover). For DN 100–DN 200

sizes, pull the clutch knob (located at the end of the lever) and

rotate the lever into the desired position.

Wiring diagram (fig. N - O)

- Actuator SM 100 for DN 32–DN 80 valves (fig. N):

1 clockwise rotation (CW)

2 anticlockwise rotation (ACW)

3 common

Auxiliary microswitch

(diagram at the end of the indicated rotation)

4 normally open NO

5 normally closed NC

6 common

- Actuator SM 200 for DN 100–DN 200 valves (fig. O):

5 clockwise rotation (CW)

6 common

7 anticlockwise rotation (ACW)

Auxiliary microswitches

(diagram at the end of the indicated rotation)

1 normally closed NC

2 common

3 normally open NO

9 normally open NO

10 common

11 normally closed NC

Safety instructions

Warnings

The following instructions must be read and understood

before installing and maintaining the device.

The symbol means:

Safety

CAUTION! YOUR SAFETY IS INVOLVED. FAILURE TO FOLLOW

THESE INSTRUCTIONS MAY RESULT IN DANGER.

THE PRODUCT SUPPLIED WITH THIS INSTRUCTION

SHEET IS CALLED “DEVICE”.

1. The device must be installed, commissioned and

maintained by a licensed technician in accordance with

national regulations and/or relevant local requirements.

2. If the device is not installed, commissioned and maintained

correctly in accordance with the instructions provided in

this manual, it may not work properly and may endanger

the user.

3. The device is not intended to be used by people

(children included) with reduced mental, physical and

sensory faculties or with lack of experience unless they

are supervised or instructed in the use of the device by a

person responsible of their safety.

4. Clean the pipes of all deposits, rust, incrustations, limescale,

welding slag and any other contaminants. The hydraulic

circuit must be clean.

5. Make sure that all connection fittings are watertight.

6. When connecting water pipes, make sure that threaded

connections are not mechanically overstressed. Over time

this may result in breakages, with consequent water leaks

which could harm people and/or damage property.

7. Water temperatures higher than 50°C may cause severe

burns. When installing, commissioning and maintaining

the device, take the necessary precautions so that these

temperatures will not endanger people.

8. If the water is particularly hard or contains a lot of impurities,

suitable filtration and treatment should be performed

to water before it enters the device, in accordance with

current legislation. Otherwise the device may be damaged

and will not work properly.

9. For optimal operation, any air in the medium must

be removed. For safety reasons, due to the high

compressibility of air, testing the entire system, and

especially the valves, for watertightness using compressed

air is not recommended.

10. Any use of the device other than its intended use is

prohibited.

11. The device is not suitable for use in agricultural applications.

12. Any coupling of the device with other system components

must be made while taking the operational characteristics

of both units into consideration. An incorrect coupling

could compromise the operation of the device and/or

system.

1. CAUTION: Risk of electric shock. Live parts. Cut off the

electric supply before opening the device box

2. Wiring must be made according to the state of the art and,

in case of connection to the electric network, the minimum

cross-section of the cable must be equal to 0,75 mm

2

.

3. During installation and maintenance procedures, always

take care to avoid direct contact with live or potentially

hazardous parts.

4. The device must be installed in a specific area and must not

be exposed to leakages or humidity, direct sunlight, bad

weather, sources of heat or high-intensity electromagnetic

fields. This device cannot be used in areas at risk of

explosion or fire.

5. The device must have a separate connection to an

independent bipolar switch. If the equipment needs

maintenance, cut off the electric supply before any work

is carried out. Do not use devices with automatic or timed

reset, or which may be reset accidentally.

6. Use suitable automatic protection devices in accordance

with the electrical characteristics of the zone in which

the device is installed and in compliance with current

legislation.

7. The device must always be earthed before it is connected

to the electric supply. If the device needs to be removed,

the earth connection should always be disconnected after

the other electrical wires. Make sure that the building has

been earthed professionally, in accordance with current

legislation.

Declaration of conformity

We C.N.T. CASPANI SRL declare that our motorized valves

are constructed in accordance with directives 2014/30/EC e

2014/35/EC and assume full responsibility for conformity with

the standards laid down therein when operated according fo

their intended purpose, as described in the operated hand-

book.

Manufactured by

CNT CASPANI S.R.L.

CALEFFI S.p.A.

S.R. 229, N. 25

28010 Fontaneto d’Agogna (NO)

Italia

X

M

1 2 3 4 5 6 7 8 9 10 11

CA

CA CA CA

CA CA S

S

W R B

CW

CW

ACW

ACW

L

N

CW

ACW

L

N

1 2 3 4 5 6

CW

M

A

Size

Kv (m

3

/h)

Size

Kv (m

3

/h)

DN 32/40

149

DN 100

861

DN 50

207

DN 125

1345

DN 65

351

DN 150

1937

DN 80

520

DN 200

3445

B

A

DN 32/40

DN 50

DN 65

DN 80

B

56

62

69

94

C

110

120

135

141

D

152

152

152

152

E

118

118

118

118

F

50

50

50

50

I

79

79

79

79

G

38

50

52

52

H

116

130

137

143

A

DN 100

DN 125

DN 150

DN 200

B

106

127

133

170

C

165

180

193

225

D

227

227

227

227

E

192

192

192

192

F

97

97

97

97

I

108

108

108

108

G

58

65

65

65

H

147

180

206

257

I

H

A

A

B

C

D

E

F

I

H

G

G

E

F

B

C

D

Mass (kg)

3,5

4,5

4,5

5

Mass (kg)

9

11

12

16

X

X

X

E

F

M

1 2 3 4 5 6 7 8 9 10 11

CA

CA CA CA

CA CA S

S

W R B

CW

CW

ACW

ACW

L

N

CW

ACW

L

N

1 2 3 4 5 6

CW

M

G

H

I

L

M

N

O

C

D

639

042

DN 32 /40 230 V

639

052

DN 50 230 V

639

062

DN 65 230 V

639

082

DN 80 230 V

639

044

DN 32 /40 24 V

639

054

DN 50 24 V

639

064

DN 65 24 V

639

084

DN 80 24 V

639

102

DN 100 230 V

639

122

DN 125 230 V

639

152

DN 150 230 V

639

202

DN 200 230 V

639

104

DN 100

24 V

639

124

DN 125 24 V

639

154

DN 150 24 V

639

204

DN 200 24 V